Nissan March K13. Manual - part 280

EM-54

< REMOVAL AND INSTALLATION >

[HR12DE]

CAMSHAFT

1.

Support the bottom surface of engine using a transmission jack, and then remove the engine mounting

bracket and insulator (RH). Refer to

2.

Remove rocker cover. Refer to

.

3.

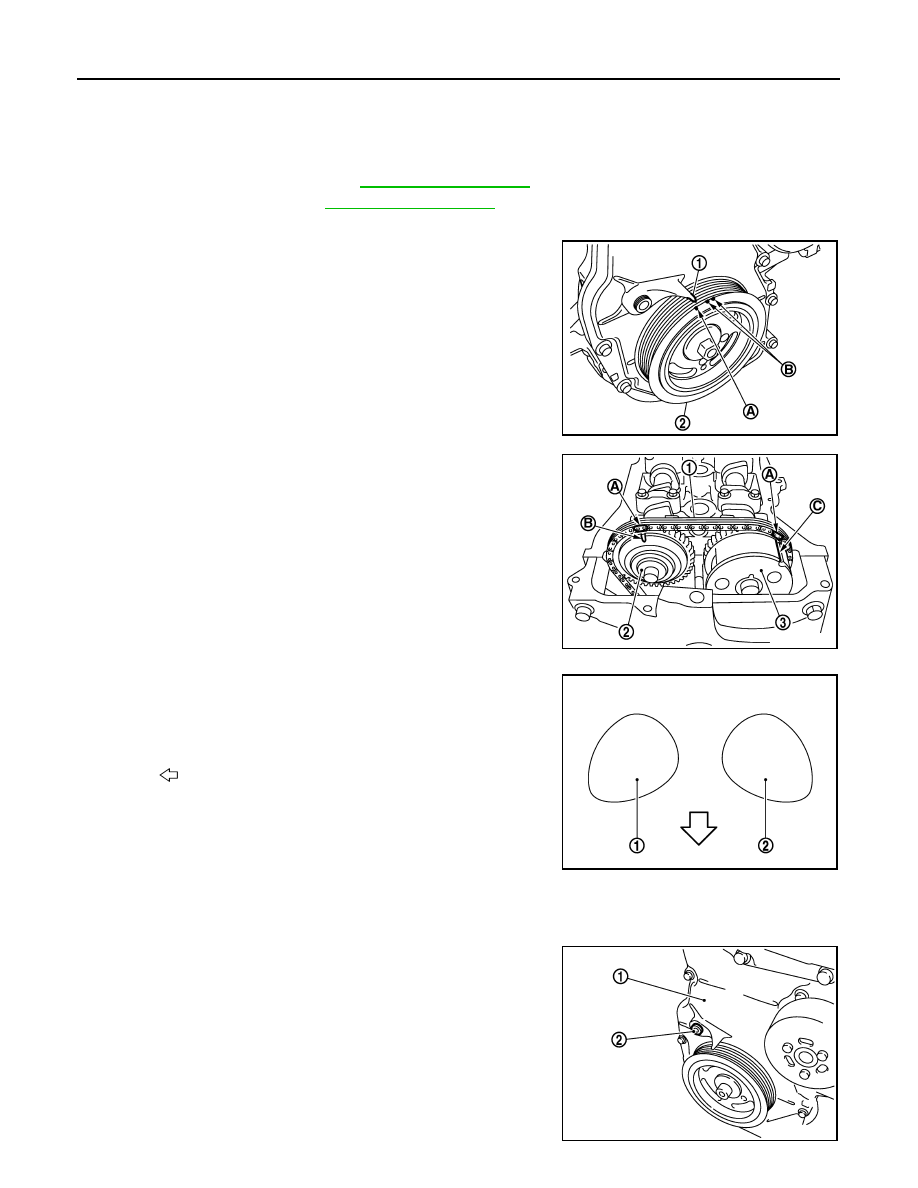

Place cylinder No. 1 at TDC with the following procedure.

a.

Rotate crankshaft pulley (2) clockwise and align TDC mark

(without paint mark) (A) to timing indicator (1) on front cover.

b.

Check that the matching marks on each camshaft sprocket are

in the position as shown in the figure.

• If the matching marks are not in place, rotate crankshaft pull

one more turn to satisfy the position shown in figure.

c.

Check that the cam nose of cylinder 1 is positioned as shown in

the figure.

d.

Paint matching marks (A) on the timing chain links

4.

Secure the plunger of chain tensioner in the fully compressed position with the following procedure. And

then, loosen the timing chain tension.

a.

Remove the plug (2) from the front cover (1).

·Step 9

: The camshaft (EXH) can be removed simultaneously with the camshaft (INT).

·Step 10

: When the camshaft sprocket (INT) mounting bolt is removed, the lifting up of cam-

shaft is not necessary.

B

: White paint mark (Not use for service)

PBIC3673E

1.

: Timing chain

2.

: Camshaft sprocket (EXH)

3.

: Camshaft sprocket (INT)

A

: Matching mark (Paint)

B

: Matching mark (Stamp)

C

: Matching mark (Peripheral stamp line)

1.

: Camshaft (EXH)

2.

: Camshaft (INT)

: Cylinder head side

PBIC3674E

JPBIA3413ZZ

PBIC3675E