Nissan March K13. Manual - part 283

EM-66

< REMOVAL AND INSTALLATION >

[HR12DE]

CAMSHAFT

1.

Install camshaft in cylinder head. Refer to

EM-53, "Removal and Installation"

2.

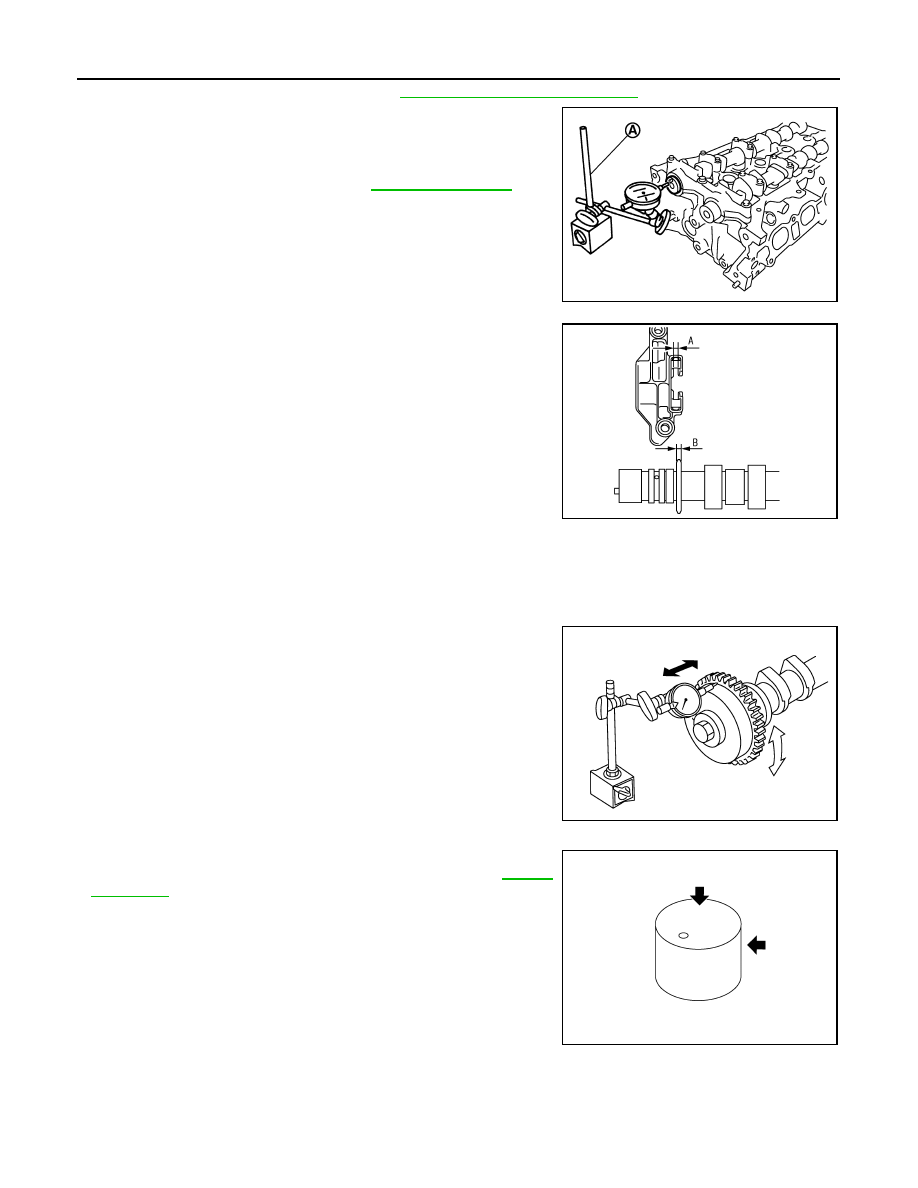

Install a dial indicator (A) in thrust direction on front end of cam-

shaft. Measure the camshaft end play on the dial indicator when

camshaft is moved forward/backward (in direction to axis).

• Measure the following parts if out of the standard.

- Dimension “A” for cylinder head No. 1 journal bearing

- Dimension “B” for camshaft thrust

• Refer to the standards above, and then replace camshaft and/

or cylinder head.

Camshaft Sprocket Runout

1.

Put V-block on precise flat table, and support No. 2 and 5 journals of camshaft.

CAUTION:

Never support No. 1 journal (on the side of camshaft sprocket) because it has a different diameter

from the other four locations.

2.

Measure the camshaft sprocket runout with a dial indicator.

(Total indicator reading)

• If it exceeds the limit, replace camshaft sprocket.

Valve Lifter

Check if surface of valve lifter has any wear or cracks.

• If anything above is found, replace valve lifter. Refer to

.

Valve Lifter Clearance

VALVE LIFTER OUTER DIAMETER

Standard and Limit

: Refer to

PBIC3694E

Standard

: 4.000 - 4.030 mm (0.1574 - 0.1586 in)

Standard

: 3.877 - 3.925 mm (0.1526 - 0.1545 in)

KBIA3345J

Limit

: 0.15 mm (0.0059 in)

KBIA1493J

KBIA0182E