Nissan March K13. Manual - part 275

EM-34

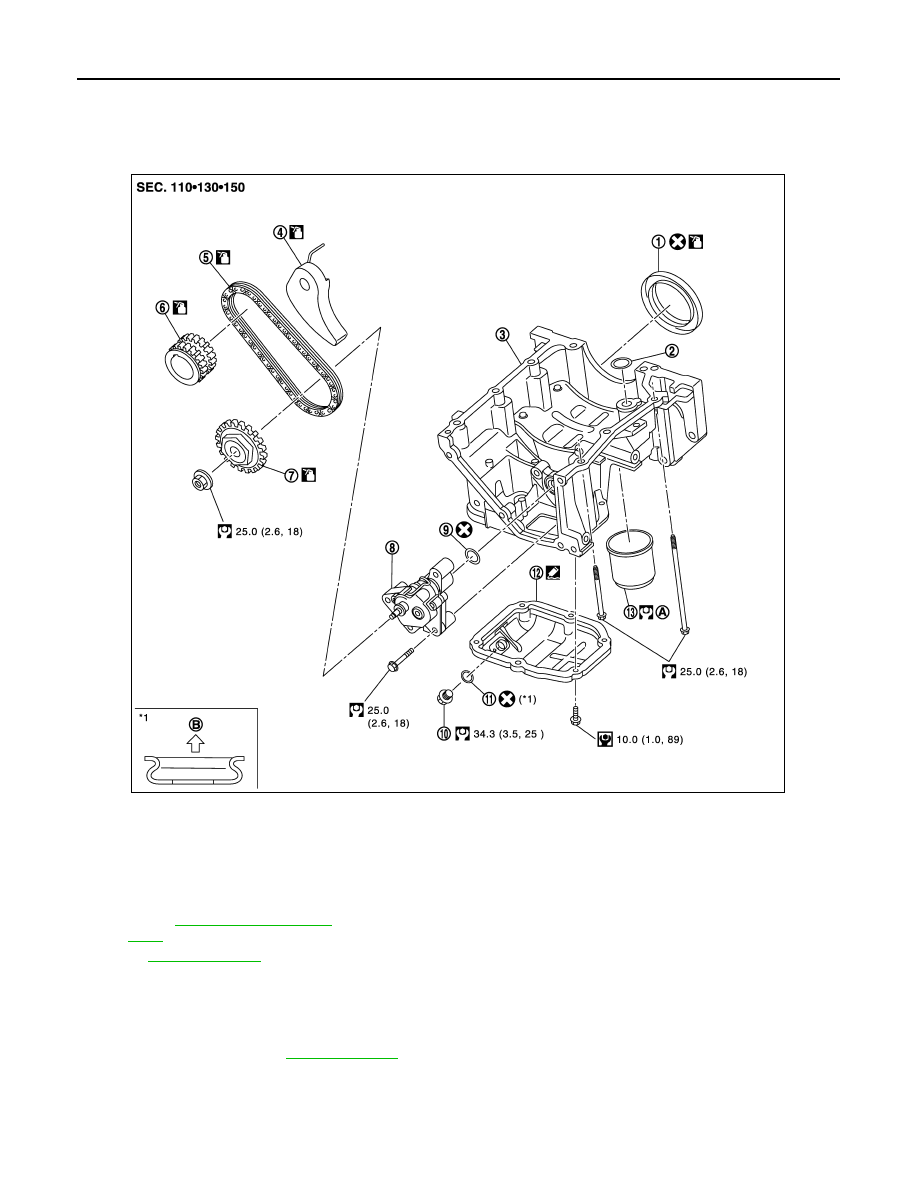

< REMOVAL AND INSTALLATION >

[HR12DE]

OIL PAN (LOWER)

OIL PAN (LOWER)

Exploded View

INFOID:0000000005988184

Removal and Installation

INFOID:0000000005988185

REMOVAL

1.

Drain engine oil. Refer to

.

2.

Remove oil pan (lower) with the following procedure:

1.

Rear oil seal

2.

O-ring

3.

Oil pan (upper)

4.

Oil pump chain tensioner

5.

Oil pump drive chain

6.

Crankshaft sprocket

7.

Oil pump sprocket

8.

Oil pump

9.

O-ring

10. Drain plug

11.

Drain plug washer

12. Oil pan (lower)

13. Oil filter

A.

B.

Oil pan (lower) side

Refer to

for symbols in the figure.

JPBIA3384GB