Nissan March K13. Manual - part 273

EM-26

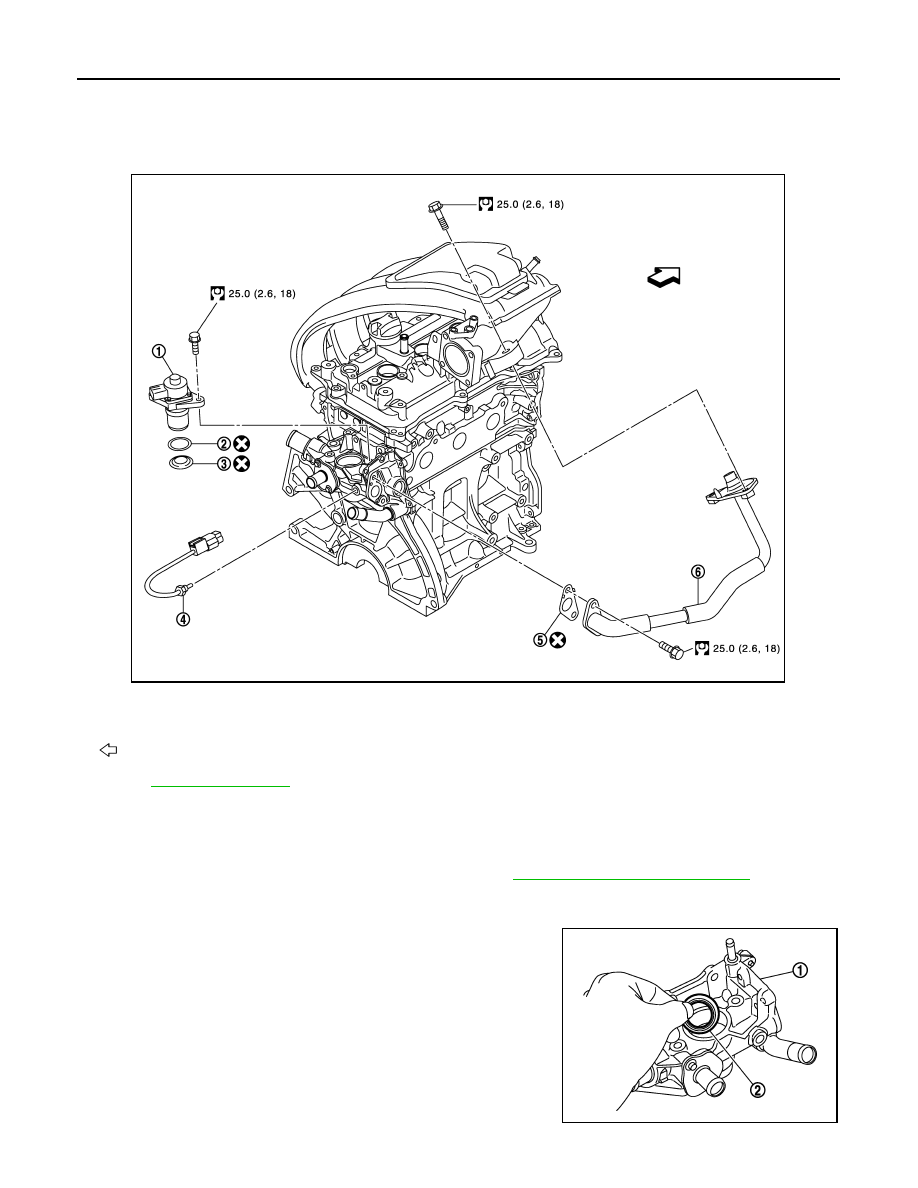

< REMOVAL AND INSTALLATION >

[HR12DE]

EGR SYSTEM

EGR SYSTEM

Exploded View

INFOID:0000000006038725

• Refer to

for symbol marks except in the above.

Removal and Installation

INFOID:0000000006038726

REMOVAL

1.

Remove air duct (inlet) and air cleaner assembly. Refer to

EM-24, "Removal and Installation"

.

2.

Remove EGR guide tube.

3.

Remove EGR volume control valve.

• Remove holder (2) from water outlet (1) if removed from EGR

volume control valve.

CAUTION:

• Do not damage or impact EGR volume control valve.

• Do not disassemble or adjust EGR volume control valve.

1.

EGR volume control valve

2.

O-ring

3.

Holder

4.

EGR temperature sensor

5.

Gasket

6.

EGR guide tube

Engine front

JPBIA3414GB

JPBIA3462ZZ