Nissan March K13. Manual - part 271

EM-18

< PERIODIC MAINTENANCE >

[HR12DE]

DRIVE BELT

PERIODIC MAINTENANCE

DRIVE BELT

Checking

INFOID:0000000005988168

• Inspection should be done only when engine is cold or over 30

minutes after the engine is stopped.

• Visually check belts for wear, damage, and cracks on inside and

edges.

• Turn crankshaft pulley two time clockwise, and check tension on all pulleys is equal before doing the test.

• When measuring deflection, apply 98 N (10 kg, 22 lb) at the ( ) marked point.

• Measure the belt tension and frequency with acoustic tension gauge (commercial service tool) at the ( )

marked point.

CAUTION:

• When the tension and frequency are measured, the acoustic tension gauge should be used.

• When checking immediately after installation, first adjust it to the specified value. Then, after turning

crankshaft two turns or more, readjust to the specified value to avoid variation in deflection between

pulleys.

Tension Adjustment

INFOID:0000000005988169

CAUTION:

• When belt is replaced with new one, adjust belt tension to the value for “New belt”, because new belt

will not fully seat in the pulley groove.

• When tension of the belt being used exceeds “Limit”, adjust it to the value for “After adjusted”.

• When installing a belt, check it is correctly engaged with the pulley groove.

• Never allow oil or engine coolant to get on the belt.

• Never twist or bend the belt strongly.

1.

Remove front fender protector (RH). Refer to

EXT-17, "FENDER PROTECTOR : Exploded View"

.

2.

Loosen the idler pulley lock nut (A) from the tightening position

with the specified torque by 45 degrees.

CAUTION:

• When the lock nut is loosened excessively, the idler pulley tilts and the correct tension adjust-

ment cannot be performed. Never loosen it excessively (more than 45 degrees).

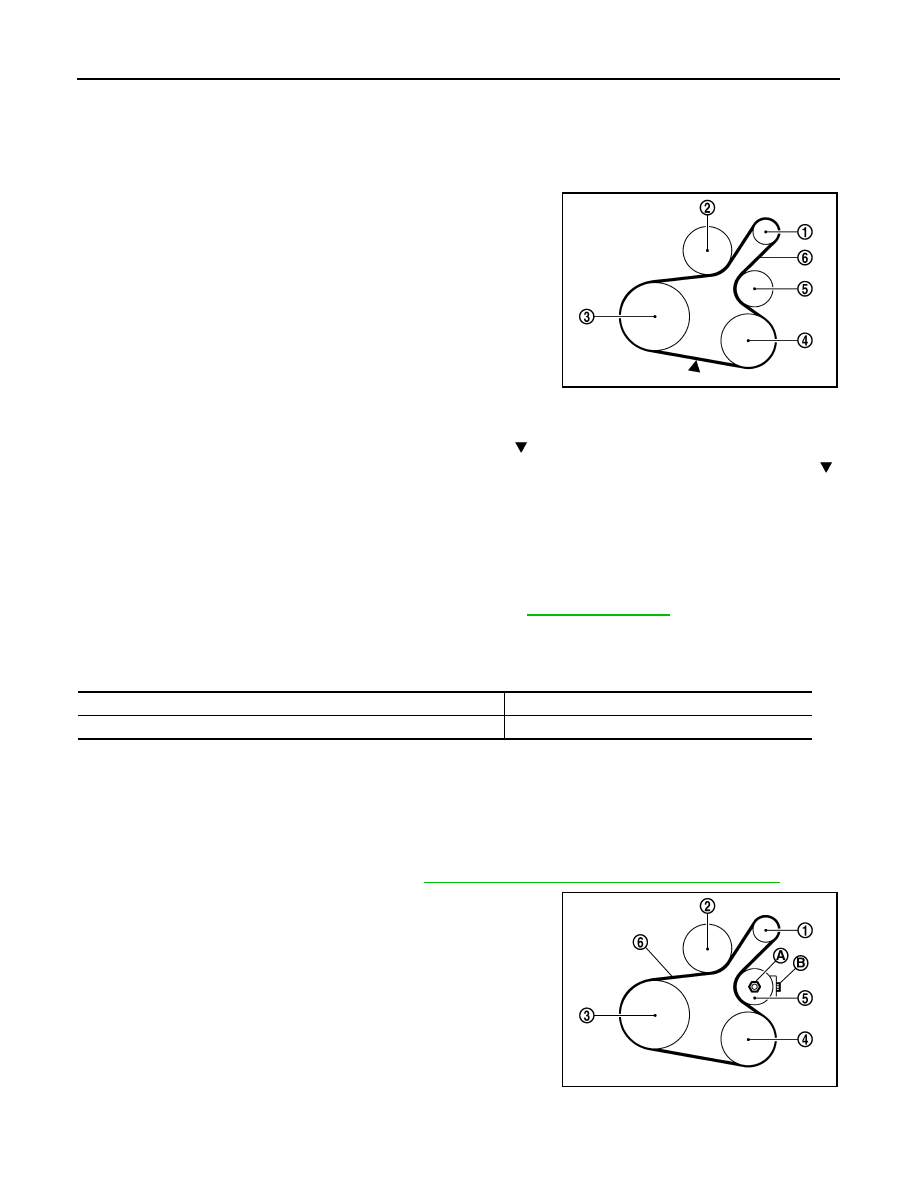

1

: Alternator

2

: Water pump

3

: Crankshaft pulley

4

: A/C compressor (With A/C models)

: Idler pulley (Without A/C models)

5

: Idler pulley

6

: Drive belt

Belt Deflection/Belt Tension and Frequency: Refer to

PBIC3642E

Location

Location of adjuster and tightening method

Drive belt

Adjusting bolt on idler pulley

1

: Alternator

2

: Water pump

3

: Crankshaft pulley

4

: A/C compressor (with A/C models)

: Idler pulley (without A/C models)

5

: Idler pulley

6

: Drive belt

PBIC3643E