содержание .. 93 94 95 96 ..

Nissan GT-R. Manual - part 95

EM-28

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Spark Plug

INFOID:0000000009162879

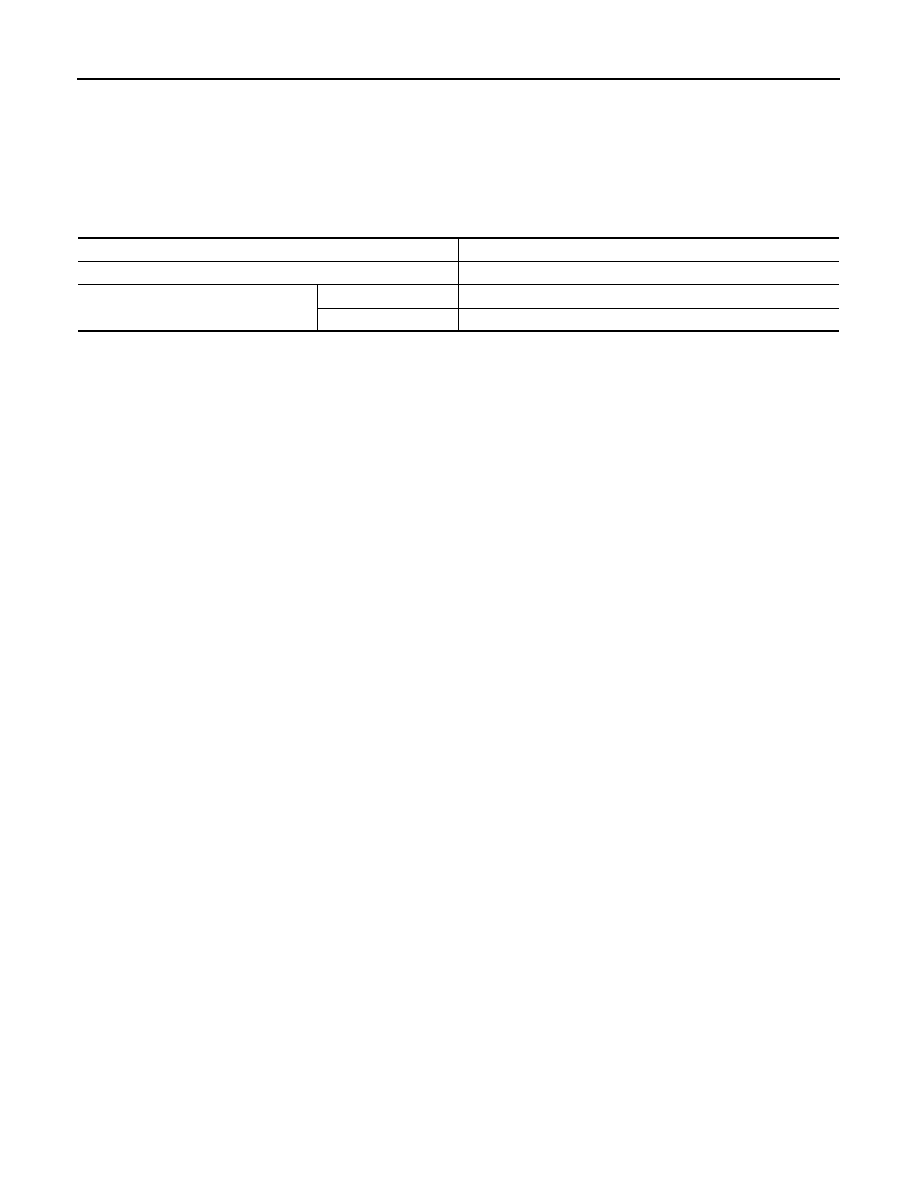

SPARK PLUG

Unit: mm (in)

Make

NGK

Standard type

DILKAR8A8

Gap (Nominal)

Standard

0.7 - 0.8 (0.028 - 0.031)

Limit

1.0 (0.039)