Nissan Pathfinder (2012 year). Manual - part 332

P0300, P0301, P0302, P0303, P0304, P0305, P0306, P0307, P0308 MISFIRE

EC-737

< DTC/CIRCUIT DIAGNOSIS >

[VK56DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

2. Is there any cylinder which does not produce a momentary engine speed drop?

Without CONSULT

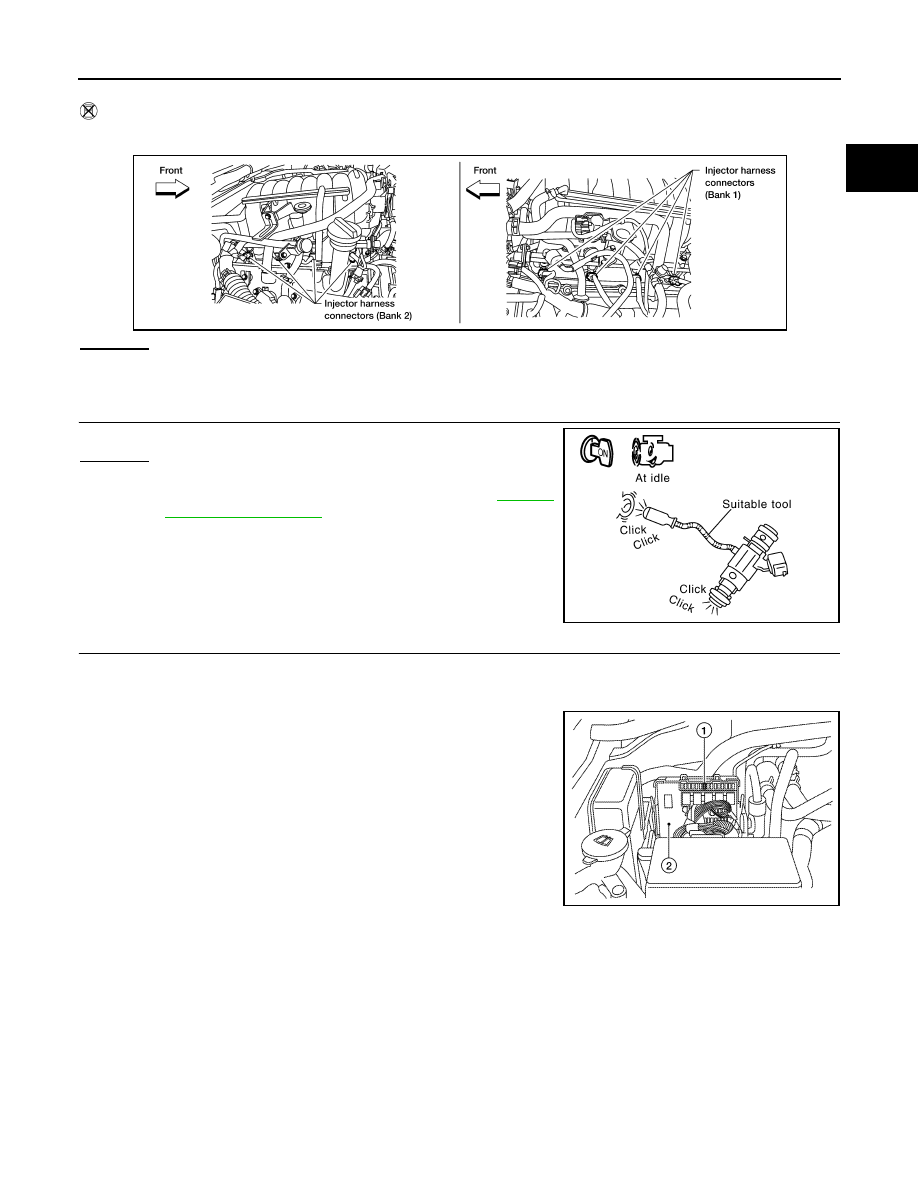

When disconnecting each fuel injector harness connector one at a time, is there any cylinder which does not

produce a momentary engine speed drop?

Yes or No

Yes

>> GO TO 4.

No

>> GO TO 7.

4.

CHECK FUEL INJECTOR

Does each fuel injector make an operating sound at idle?

Yes or No

Yes

>> GO TO 5.

No

>> Check fuel injector(s) and circuit(s). Refer to

.

5.

CHECK FUNCTION OF IGNITION COIL-I

CAUTION:

Perform the following procedure in a place with no combustible objects and good ventilation.

1. Turn ignition switch OFF.

2. Remove fuel pump fuse (1) in IPDM E/R (2) to release fuel pres-

sure.

NOTE:

Do not use CONSULT to release fuel pressure, or fuel pressure

applies again during the following procedure.

3. Start engine.

4. After engine stalls, crank it 2 or 3 times to release all fuel pres-

sure.

5. Turn ignition switch OFF.

6. Remove all ignition coil harness connectors to avoid the electri-

cal discharge from the ignition coils.

7. Remove ignition coil and spark plug of the cylinder to be

checked.

8. Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

9. Connect spark plug and harness connector to ignition coil.

BBIA0374E

PBIB1986E

ALBIA0351ZZ

August 2012

2012 Pathfinder