Nissan Pathfinder (2012 year). Manual - part 330

P0172, P0175 FUEL INJECTION SYSTEM FUNCTION

EC-721

< DTC/CIRCUIT DIAGNOSIS >

[VK56DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

2. Listen for an exhaust gas leakage before three way catalyst (manifold).

OK or NG

OK

>> GO TO 2.

NG

>> Repair or replace malfunctioning part.

2.

CHECK FOR INTAKE AIR LEAKAGE

Listen for an intake air leakage after the mass air flow sensor.

OK or NG

OK

>> GO TO 3.

NG

>> Repair or replace malfunctioning part.

3.

CHECK AIR FUEL RATIO SENSOR 1 INPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect corresponding air fuel ratio (A/F) sensor 1 harness connector.

3. Disconnect ECM harness connector.

4. Check harness continuity between A/F sensor 1 terminals and ECM terminals as per the following.

Refer to Wiring Diagram.

5. Check harness continuity between the following terminals and ground.

Refer to Wiring Diagram.

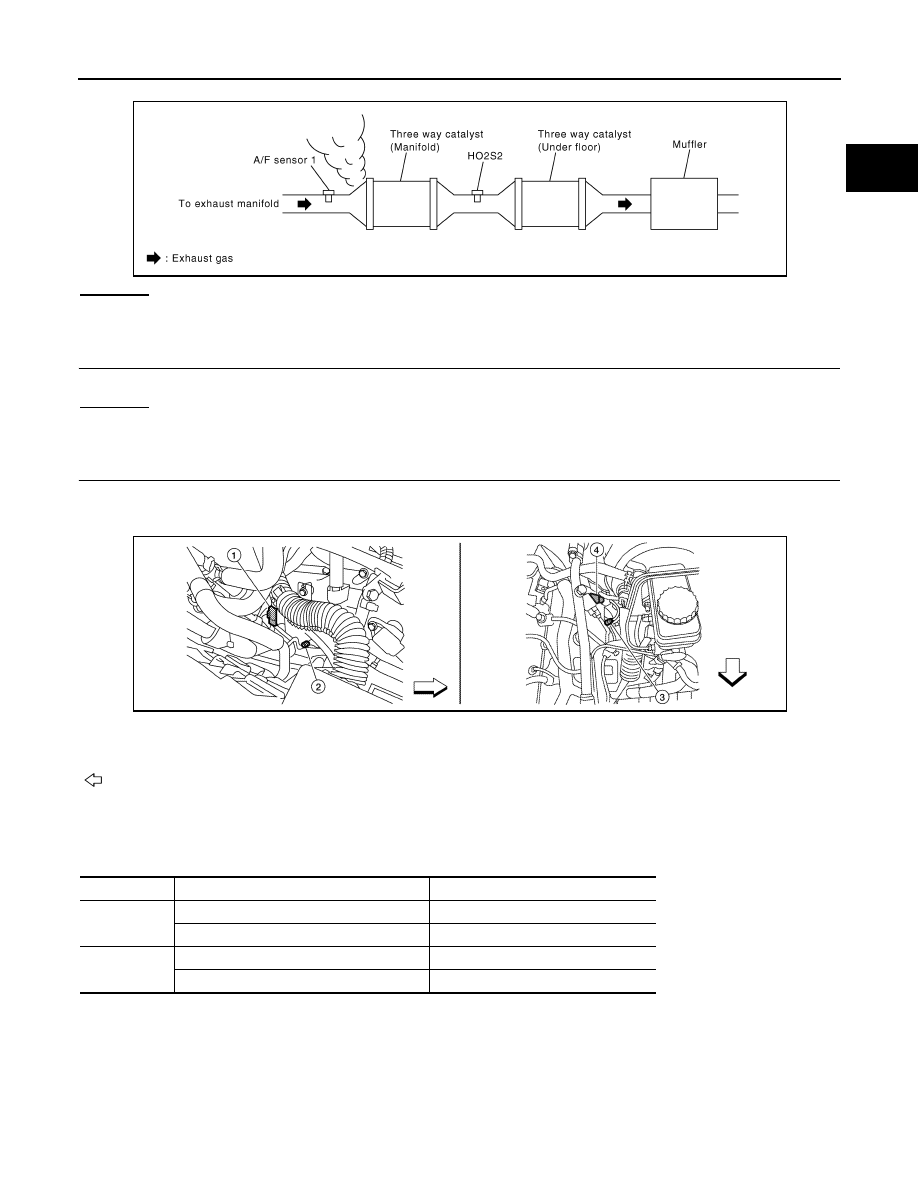

PBIB1216E

ALBIA0360ZZ

1.

A/F sensor 1 (bank 2) harness connector

2.

A/F sensor 1 (bank 2)

3.

A/F sensor 1 (bank 1)

4.

A/F sensor 1 (bank 1) harness connector

: Vehicle front

A/F sensor 1 terminal

ECM terminal

Bank 1

1

35

2

56

Bank 2

1

16

2

75

Continuity should exist.

August 2012

2012 Pathfinder