Nissan Pathfinder (2007 year). Manual - part 34

TRANSMISSION ASSEMBLY

AT-243

D

E

F

G

H

I

J

K

L

M

A

B

AT

2007 Pathfinder

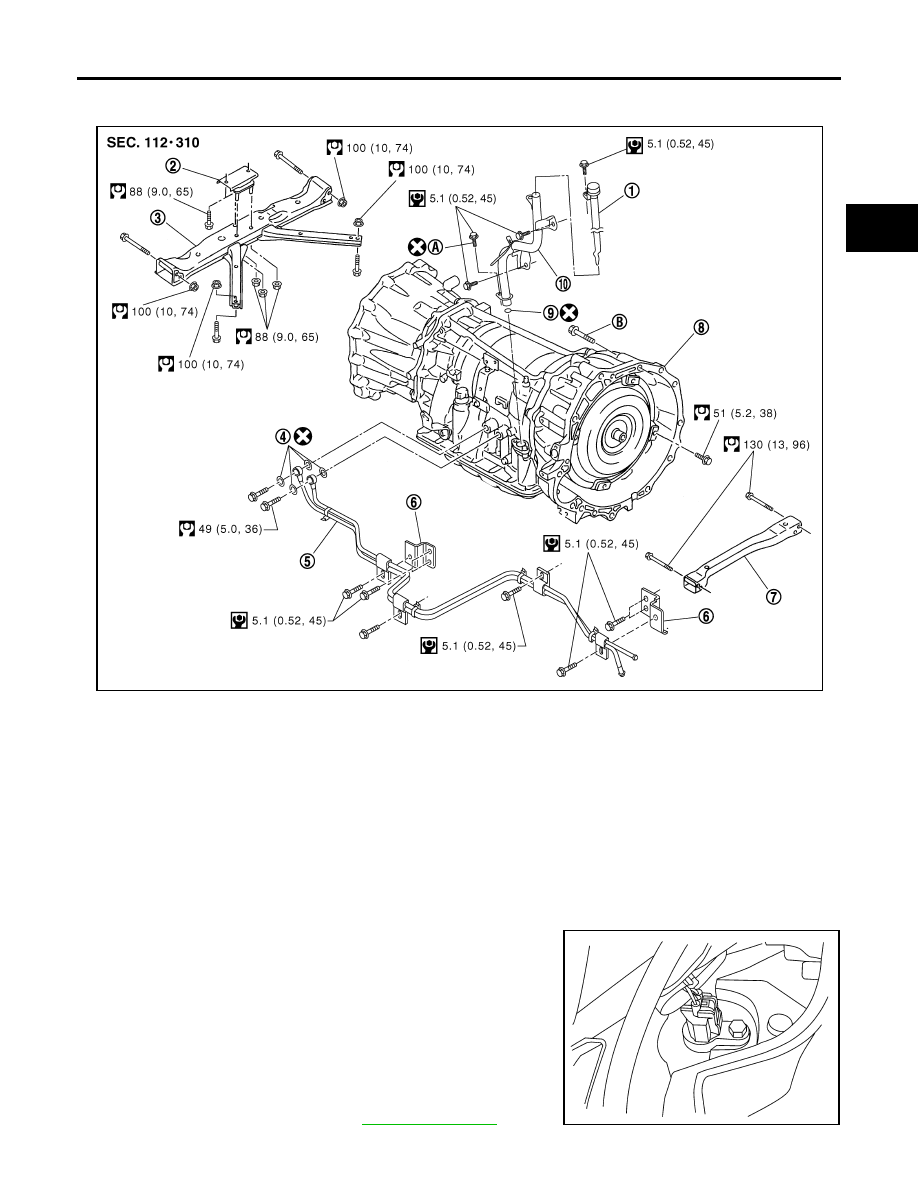

Removal and Installation (4WD)

ECS00ELY

COMPONENTS

REMOVAL

CAUTION:

When removing the A/T assembly from engine, first remove the crankshaft position sensor (POS) from

the A/T assembly.

1.

Disconnect the negative battery terminal.

2.

Remove the A/T fluid level gauge.

3.

Remove the LH fender protector.

4.

Remove the crankshaft position sensor (POS) from the A/T

assembly.

CAUTION:

●

Do not subject it to impact by dropping or hitting it.

●

Do not disassemble.

●

Do not allow metal filings or foreign material to get on the

sensor's front edge magnetic area.

●

Do not place in an area affected by magnetism.

5.

Remove the undercovers using power tool.

6.

Partially drain the A/T fluid. Refer to

1.

A/T fluid level gauge

2.

Insulator

3.

A/T crossmember

4.

Copper washers

5.

A/T fluid cooler tube

6.

Bracket

7.

Front crossmember

8.

Transmission assembly

9.

O-ring

10.

A/T fluid charging pipe

A.

Self-sealing bolt

B.

Refer to installation.

WCIA0574E

LCIA0367E