Nissan Pathfinder (2007 year). Manual - part 33

ON-VEHICLE SERVICE

AT-235

D

E

F

G

H

I

J

K

L

M

A

B

AT

2007 Pathfinder

7.

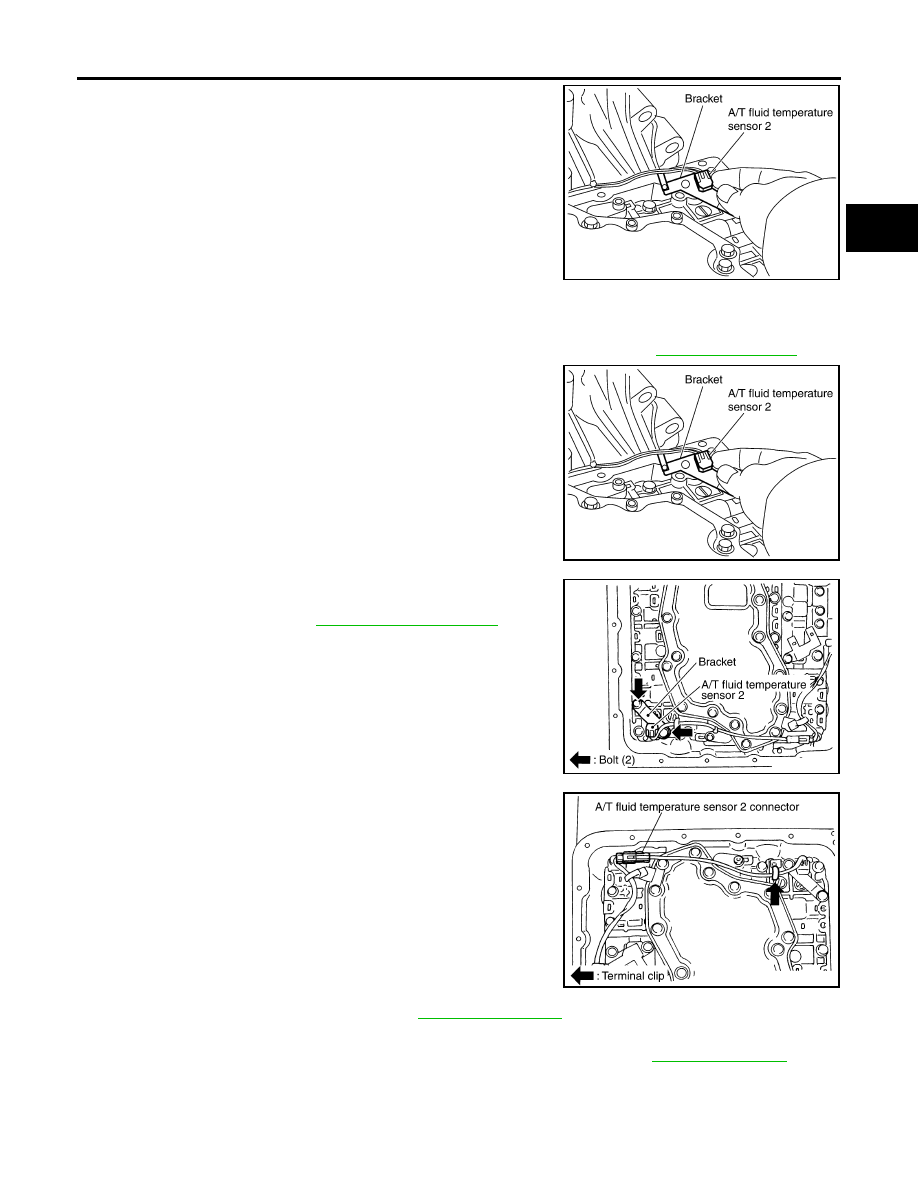

Remove bracket from A/T fluid temperature sensor 2.

Installation

CAUTION:

After completing installation, check A/T fluid leakage and fluid level. Refer to

1.

Install A/T fluid temperature sensor 2 to bracket.

2.

Install A/T fluid temperature sensor 2 (with bracket) in control

valve with TCM. Tighten A/T fluid temperature sensor 2 bolt to

the specified torque. Refer to

CAUTION:

Adjust bolt hole of bracket to bolt hole of control valve with

TCM.

3.

Connect A/T fluid temperature sensor 2 connector.

4.

Securely fasten A/T fluid temperature sensor 2 harness with ter-

minal clip.

5.

Install oil pan to transmission case. Refer to

.

6.

Connect the negative battery terminal.

7.

Refill the A/T with fluid and check the fluid level and for fluid leakage. Refer to

.

SCIA5264E

SCIA5264E

SCIA5253E

SCIA5146E