Nissan Pathfinder (2006 year). Manual - part 254

FUEL TANK

FL-15

C

D

E

F

G

H

I

J

K

L

M

A

FL

2006 Pathfinder

●

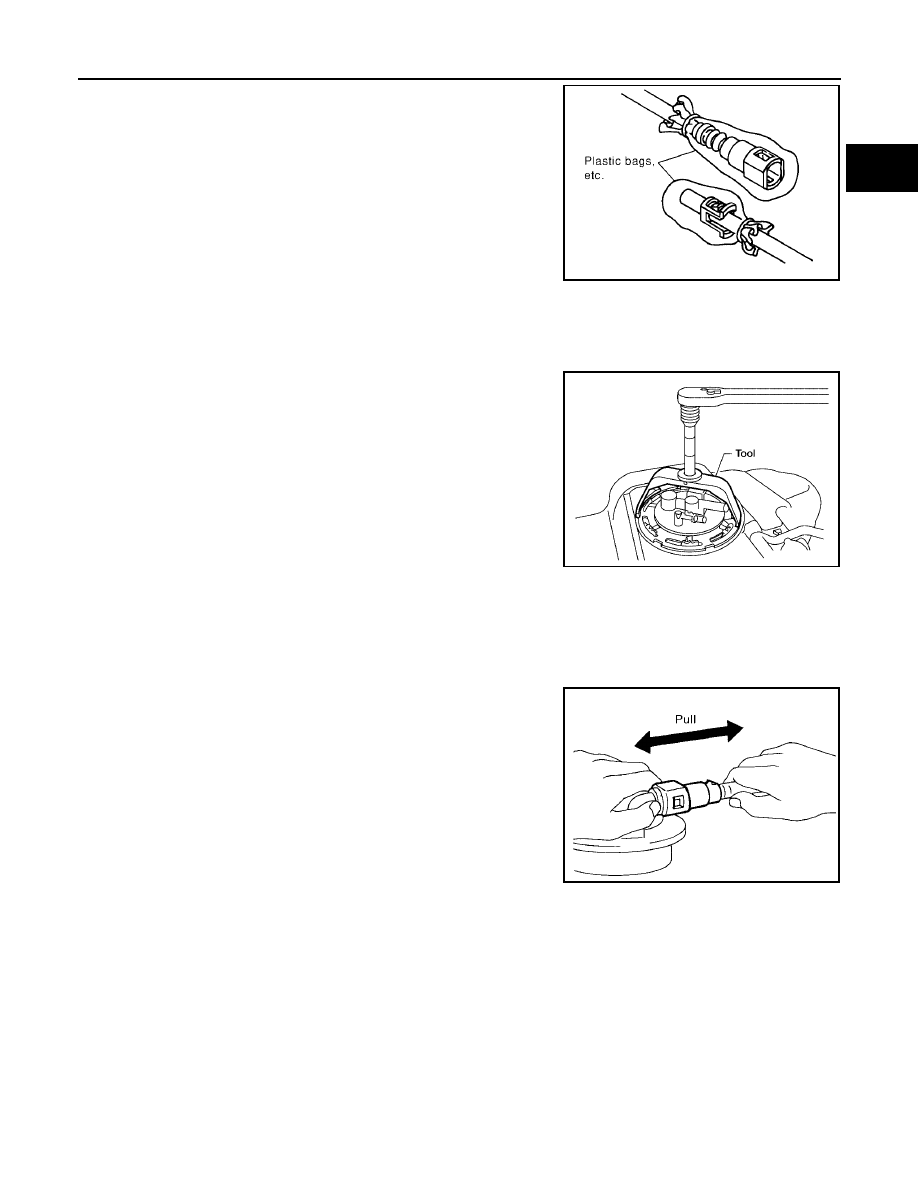

To keep the quick connector clean and to avoid damage

and contamination from foreign materials, cover the

quick connector with plastic bags or suitable material as

shown.

13. Lower the fuel tank using a suitable lift jack and remove the fuel tank.

14. Disconnect the EVAP hose from the fuel pump and remove the EVAP hose from the molded clip in the top

of the fuel tank.

15. Remove the lock ring using Tool.

16. Remove the fuel level sensor, fuel filter, and fuel pump assem-

bly.

CAUTION:

●

Do not bend the float arm during removal.

●

Avoid impacts such as dropping when handling the com-

ponents.

INSTALLATION

Installation is in the reverse order of removal.

●

Connect the quick connector as follows:

–

Check the connection for any damage or foreign materials.

–

Align the connector with the pipe, then insert the connector straight into the pipe until a click is heard.

–

After connecting the quick connector, make sure that the con-

nection is secure by checking as follows:

–

Pull the tube and the connector to make sure they are securely

connected.

–

Visually inspect the connector to make sure the two retainer tabs

are securely connected.

CAUTION:

●

Do not bend the float arm during installation.

●

Avoid impacts such as dropping when handling the compo-

nents.

INSPECTION AFTER INSTALLATION

1.

Turn the ignition switch ON but do not start engine, then check the fuel pipe and hose connections for

leaks while applying fuel pressure.

2.

Start the engine and rev it above idle, then check that there are no fuel leaks at any of the fuel pipe and

hose connections.

PBIC0163E

Tool number

:

—

(J-45722)

LBIA0445E

PBIC1653E