Nissan Pathfinder (2006 year). Manual - part 255

ON-VEHICLE SERVICE

FSU-7

C

D

F

G

H

I

J

K

L

M

A

B

FSU

2006 Pathfinder

●

Your alignment machine should be regularly calibrated in order to give correct information.

●

Check with the manufacturer of your specific alignment machine for their recommended Service/Cali-

bration Schedule.

THE ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to

.

1.

When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Do NOT use these indicators.

●

The alignment specifications programmed into your alignment machine that operate these indicators

may not be correct.

●

This may result in an ERROR.

2.

Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com-

pensate” the sensors (alignment targets or head units). Do NOT use this “Rolling Compensation”

method.

●

Use the “Jacking Compensation” method. After installing the alignment targets or head units, raise the

vehicle and rotate the wheels 1/2 turn both ways.

●

See Instructions in the alignment machine you are using for more information.

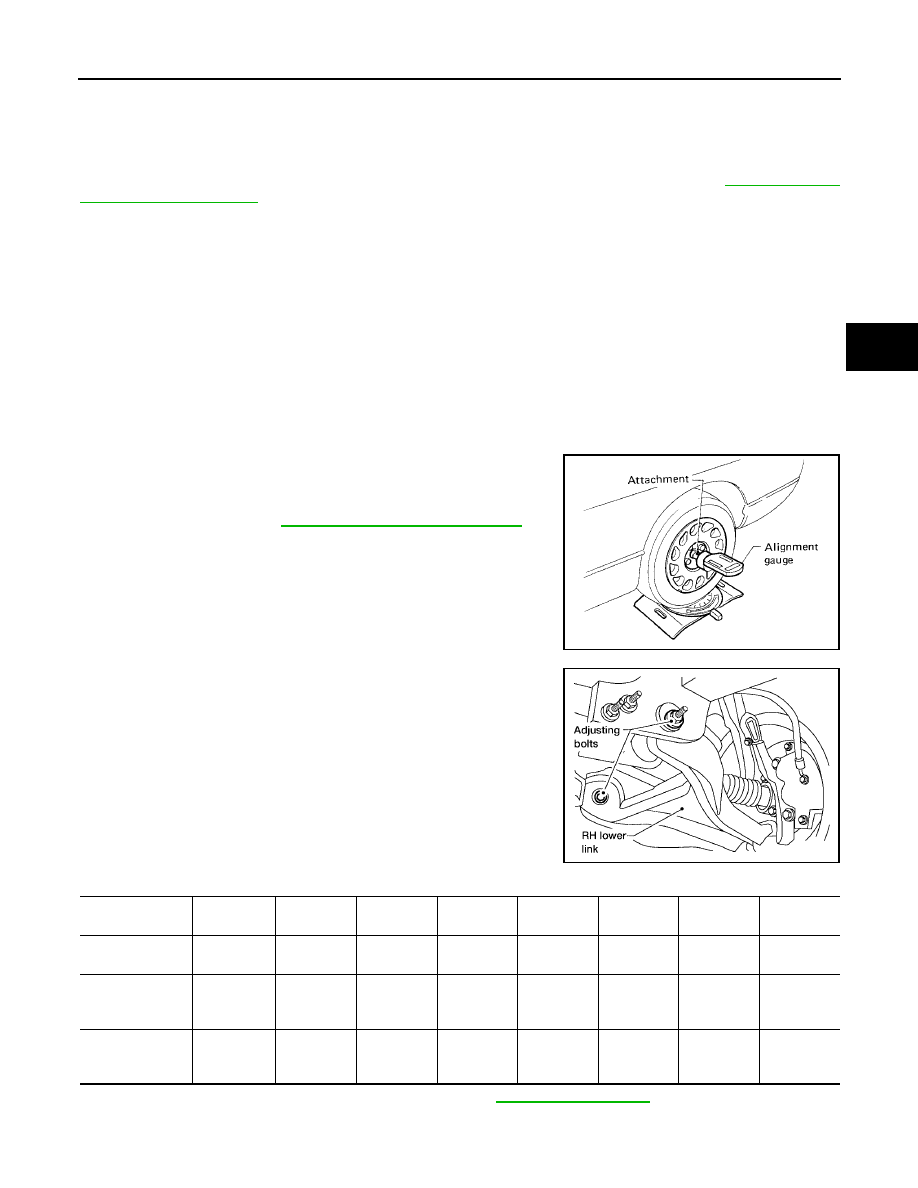

CAMBER AND CASTER

1.

Measure camber and caster of both the right and left wheels

with a suitable alignment gauge and adjust as necessary to

specification.

NOTE:

Some vehicles may be equipped with straight (non-adjustable)

lower link bolts and washers. In order to adjust camber and

caster on these vehicles, first replace the lower link bolts and

washers with adjustable (cam) bolts and washers.

2.

If outside of the specified value, adjust camber and caster using

the adjusting bolts in the front lower link.

CAUTION:

After adjusting the camber then check the toe-in.

NOTE:

Camber changes about 3' (0.05

°

) minutes with each graduation

of one adjusting bolt. Refer to table below for examples of lower

link adjusting bolt effect on camber and caster.

3.

Tighten the adjusting bolt nuts to specification. Refer to

Camber

: Refer to

FSU-6, "Front Wheel Alignment"

.

SRA096A

WEIA0115E

Rear adjusting

bolt

1 In

1 Out

1 In

1 Out

0

0

1 In

1 Out

Front adjusting

bolt

1 Out

1 In

1 In

1 Out

1 In

1 Out

0

0

Camber

Degree minute

(Decimal degree)

0 (0)

0 (0)

7' (0.12

°

)

- 7' (-0.12

°

)

3' (0.05

°

)

- 3' (-0.05

°

)

3' (0.05

°

)

- 3' (-0.05

°

)

Caster

Degree minute

(Decimal degree)

- 12' (-0.20

°

)

12' (0.20

°

)

0 (0)

0 (0)

6' (0.10

°

)

- 6' (-0.10

°

)

- 6' (-0.10

°

)

6' (0.10

°

)