содержание .. 864 865 866 867 ..

Nissan X-Trail 32. Manual - part 866

P0031, P0032 A/F SENSOR 1 HEATER

EC-593

< DTC/CIRCUIT DIAGNOSIS >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace error-detected parts.

2.

CHECK A/F SENSOR 1 HEATER OUTPUT SIGNAL CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check the continuity between A/F sensor 1 harness connector and ECM harness connector.

4.

Also check harness for short to ground and to power.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair open circuit, short to ground or short to power in harness or connectors.

3.

CHECK A/F SENSOR 1 HEATER

Check the A/F sensor 1 heater. Refer to

EC-593, "Component Inspection"

.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> GO TO 4.

4.

REPLACE AIR FUEL RATIO (A/F) SENSOR 1

Replace malfunctioning air fuel ratio (A/F) sensor 1. Refer to

CAUTION:

• Discard any A/F sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

• Before installing new A/F sensor, clean exhaust system threads using Oxygen Sensor Thread

Cleaner [commercial service tool (J-43897-18 or J-43897-12)] and approved Anti-seize Lubricant

(commercial service tool).

>> INSPECTION END

5.

CHECK INTERMITTENT INCIDENT

GI-44, "Intermittent Incident"

.

>> INSPECTION END

Component Inspection

INFOID:0000000010986311

1.

CHECK AIR FUEL RATIO (A/F) SENSOR 1

1.

Turn ignition switch OFF.

2.

Disconnect A/F sensor 1 harness connector.

3.

Check resistance between A/F sensor 1 terminals as per the following.

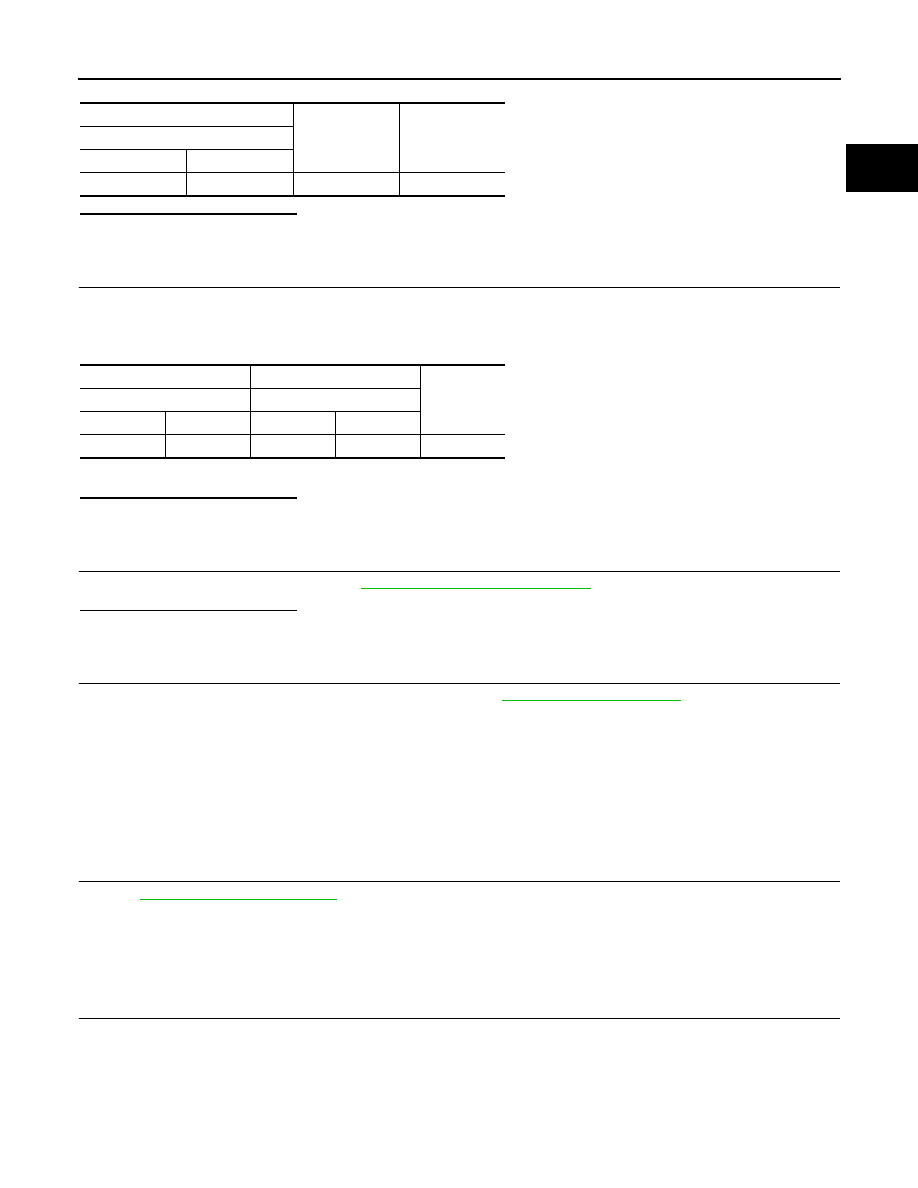

+

−

Voltage

A/F sensor 1

Connector

Terminal

F27

4

Ground

Battery voltage

+

−

Continuity

A/F sensor 1

ECM

Connector

Terminal

Connector

Terminal

F27

3

F68

53

Existed