содержание .. 2184 2185 2186 2187 ..

Nissan X-Trail 32. Manual - part 2186

TM-702

< REMOVAL AND INSTALLATION >

[CVT: RE0F10G]

ELECTRIC OIL PUMP

ELECTRIC OIL PUMP

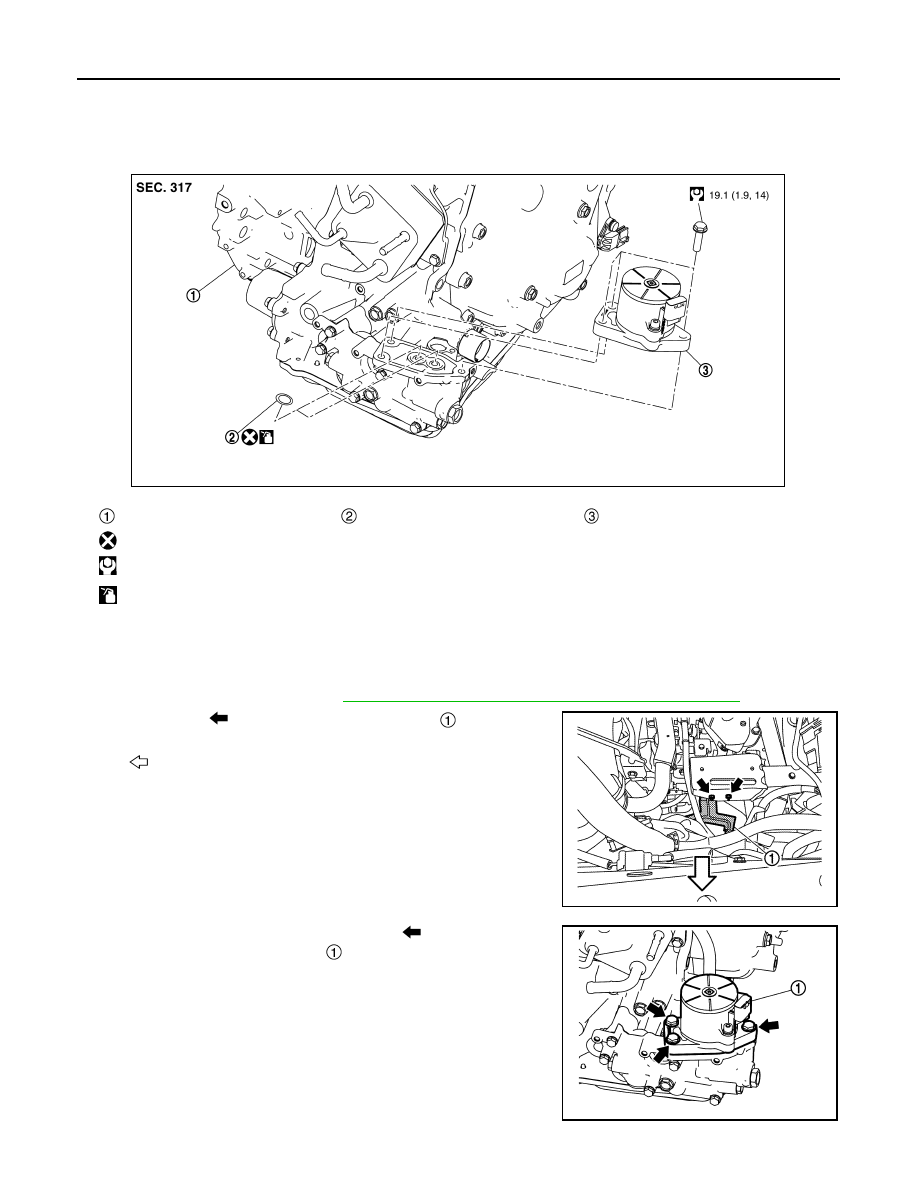

Exploded View

INFOID:0000000010742044

Removal and Installation

INFOID:0000000010742045

REMOVAL

1.

Remove the battery tray. Refer to

PG-148, "EXCEPT FOR R9M : Removal and Installation"

2.

Remove nuts (

) and remove harness bracket

.

3.

Disconnect the electric oil pump harness connector.

4.

Remove electric oil pump mounting bolts (

) and remove elec-

tric oil pump & motor assembly

.

Transaxle assembly

O-ring

Electric oil pump & motor assembly

: Always replace after every disassembly.

: N·m (kg-m, ft-lb)

: Apply CVT fluid

JSDIA5137GB

: Vehicle front

JSDIA6395ZZ

JSDIA5215ZZ