содержание .. 2029 2030 2031 2032 ..

Nissan X-Trail 32. Manual - part 2031

TM-82

< PRECAUTION >

[6MT: RS6F52A]

PRECAUTIONS

• The auto acc function is adapted to this vehicle. For this reason, even when the ignition switch is turned

to OFF position, the accessory power source does not turned OFF and continues to be supplied for a

certain amount of time.

6.

Disconnect both battery cables. The steering lock will remain released with both battery cables discon-

nected and the steering wheel can be turned.

7.

Perform the necessary repair operation.

8.

When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the ignition switch from OFF position to ON position, then to LOCK position. (The steering wheel will lock

when the ignition switch is turned to LOCK position.)

9.

Perform self-diagnosis check of all control units using CONSULT.

Precaution for Procedure without Cowl Top Cover

INFOID:0000000010921069

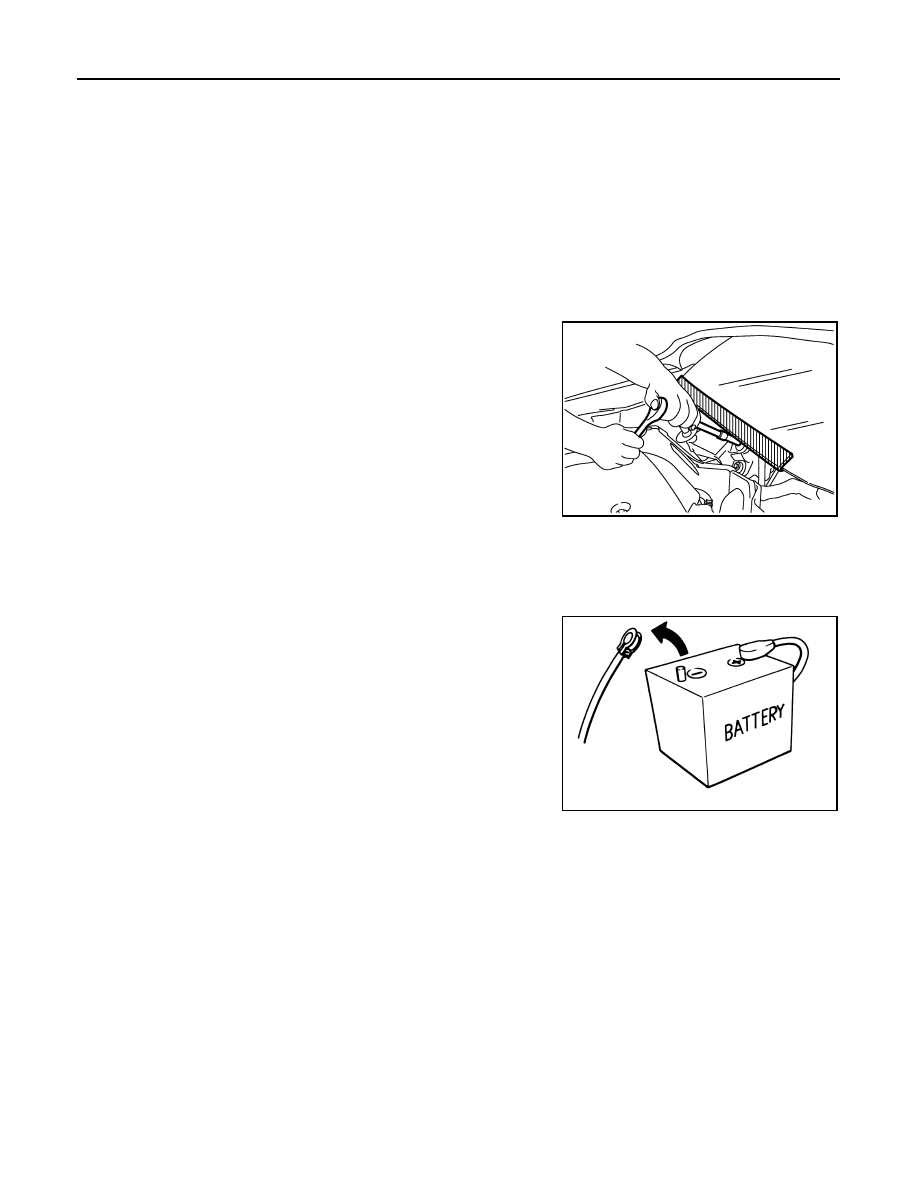

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc to prevent damage to

windshield.

Precautions for Removing Battery Terminal

INFOID:0000000010921070

• With the adoption of Auto ACC function, ACC power is automatically supplied by operating the intelligent key

or remote keyless entry or by opening/closing the driver side door. In addition, ACC power is supplied even

after the ignition switch is turned to the OFF position, i.e. ACC power is supplied for a certain fixed time.

• When disconnecting the 12V battery terminal, turn off the ACC

power before disconnecting the 12V battery terminal, observing

“How to disconnect 12V battery terminal” described below.

NOTE:

Some ECUs operate for a certain fixed time even after ignition

switch is turned OFF and ignition power supply is stopped. If the

battery terminal is disconnected before ECU stops, accidental DTC

detection or ECU data damage may occur.

• For vehicles with the 2-batteries, be sure to connect the main bat-

tery and the sub battery before turning ON the ignition switch.

NOTE:

If the ignition switch is turned ON with any one of the terminals of

main battery and sub battery disconnected, then DTC may be detected.

• After installing the 12V battery, always check "Self Diagnosis Result" of all ECUs and erase DTC.

NOTE:

The removal of 12V battery may cause a DTC detection error.

HOW TO DISCONNECT 12V BATTERY TERMINAL

Disconnect 12V battery terminal according to Instruction 1 or Instruction 2 described below.

For vehicles parked by ignition switch OFF, refer to Instruction 2.

INSTRUCTION 1

1.

Open the hood.

2.

Turn key switch to the OFF position with the driver side door opened.

3.

Get out of the vehicle and close the driver side door.

4.

Wait at least 3 minutes. For vehicle with the engine listed below, remove the battery terminal after a lapse

of the specified time.

PIIB3706J

SEF289H

D4D engine

: 20 minutes

HRA2DDT

: 12 minutes