содержание .. 1567 1568 1569 1570 ..

Nissan X-Trail 32. Manual - part 1569

MA-66

< PERIODIC MAINTENANCE >

CHASSIS MAINTENANCE

c.

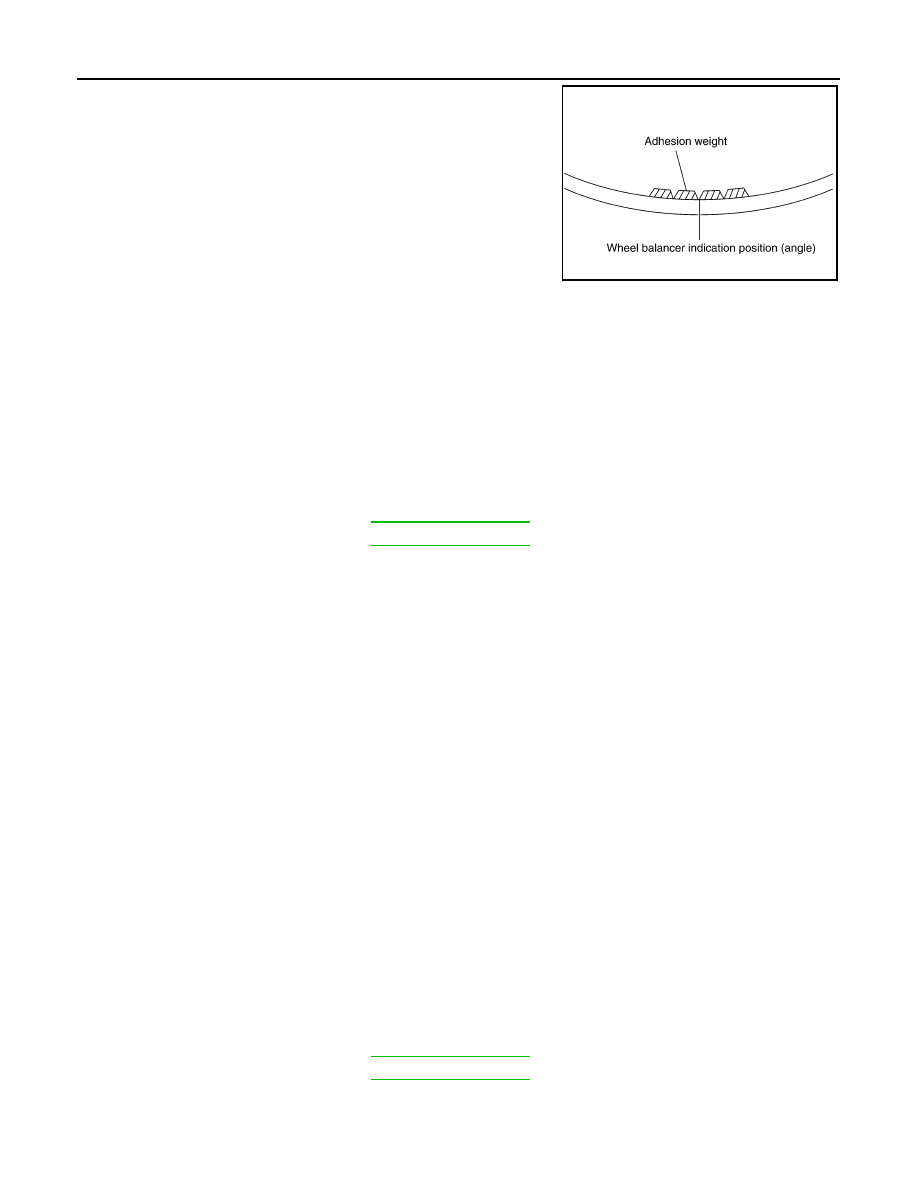

If calculated balance weight value exceeds 50 g (1.76 oz), install

two balance weight sheets in line with each other as shown in

the figure.

CAUTION:

Never install one balance weight sheet on top of another.

3.

Start the tire balance machine again.

4.

Install drive-in balance weight on inner side of road wheel in the tire balance machine indication position

(angle).

CAUTION:

Never install three or more balance weight.

5.

Start the tire balance machine. Check that the inner and outer residual unbalance value is within the

allowable unbalance value.

CAUTION:

If either residual unbalance value exceeds limit, repeat installation procedures.

WHEELS : Wheel Balance Adjustment (Steel Wheel)

INFOID:0000000010828075

PREPARATION BEFORE ADJUSTMENT

Remove balance weight from the road wheel.

CAUTION:

Never scratch the road wheel during removal.

ADJUSTMENT

• The details of the adjustment procedure are different for each model of wheel balancer. Therefore, refer to

each instruction manual.

• If a tire balance machine has adhesion balance weight mode settings and drive-in weight mode setting,

select and adjust a drive-in weight mode suitable for steel wheels.

1.

Set road wheel to wheel balancer, and then start wheel balancer.

2.

Install balance weight to road wheel according to the unbalance and position (angle) displayed on wheel

balancer.

CAUTION:

• Always use genuine NISSAN balance weights.

• Balance weights are non-reusable; always replace with new ones.

• Always use a plastic hammer when attaching the weight.

• Never install three or more balance weights on one side.

3.

Start the tire balance machine. Check that the inner and outer residual unbalance value is within the

allowable unbalance value.

CAUTION:

If either residual unbalance value exceeds limit, repeat installation procedures.

PEIA0033E

Allowable unbalance value

Dynamic (At flange)

: Refer to

.

Static (At flange)

: Refer to

.

Allowable unbalance value

Dynamic (At flange)

: Refer to

.

Static (At flange)

: Refer to

.