содержание .. 1566 1567 1568 1569 ..

Nissan X-Trail 32. Manual - part 1568

MA-62

< PERIODIC MAINTENANCE >

CHASSIS MAINTENANCE

TRANSFER OIL [TY21C (QR25DE)] : Refilling

INFOID:0000000011008829

1.

Remove filler plug

and gasket. Then fill with new transfer oil

until oil level reaches the specified level near filler plug mounting

hole.

2.

Leave the vehicle for 3 minutes, and check the oil level again.

3.

Before installing filler plug, set a new gasket. Install filler plug to transfer assembly and tighten to the spec-

ified torque. Refer to

.

CAUTION:

Never reuse gasket.

TRANSFER OIL (TY30A)

TRANSFER OIL (TY30A) : Inspection

INFOID:0000000011008830

OIL LEAKAGE

Check transfer surrounding area (oil seal, drain plug, and filler plug etc.) for oil leakage.

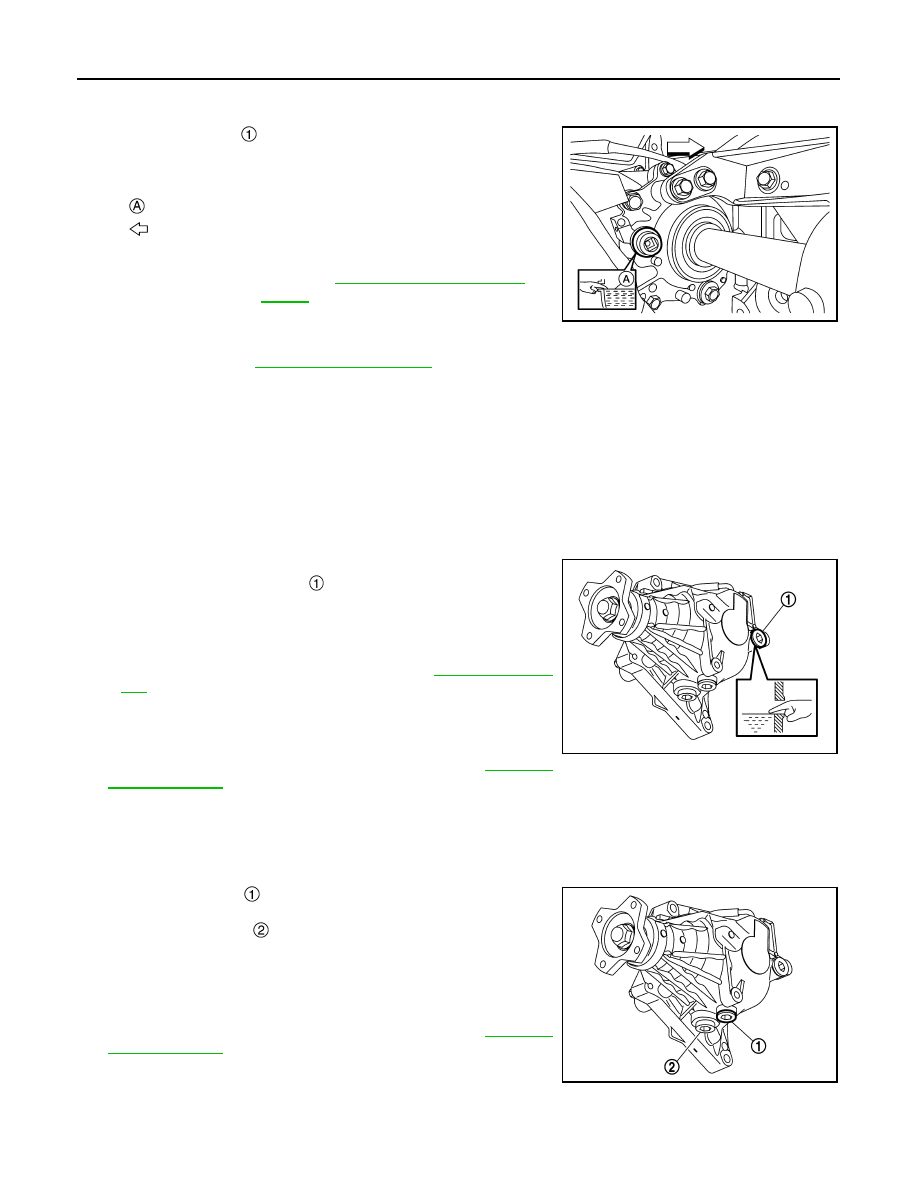

OIL LEVEL

1.

Check oil level from filler plug mounting hole as shown in the fig-

ure, after removing filler plug

and gasket from transfer assem-

bly.

CAUTION:

Turn the ignition switch OFF while checking oil level.

• Oil level should be level with bottom of filler plug mounting

hole. Add transfer oil if necessary. Refer to

.

2.

Set a gasket on filler plug and install it on transfer assembly.

CAUTION:

Never reuse gasket.

3.

Tighten filler plug to the specified torque. Refer to

TRANSFER OIL (TY30A) : Draining

INFOID:0000000011008831

1.

Run the vehicle to warm up the transfer unit sufficiently.

2.

Stop the vehicle and turn the ignition switch OFF.

3.

Remove drain plug

and gasket.

CAUTION:

Never remove plug

for tooth contact test.

4.

Drain transfer oil.

5.

Set a gasket on drain plug and install it to transfer assembly.

CAUTION:

Never reuse gasket.

6.

Tighten drain plug to the specified torque. Refer to

: Oil level

: Vehicle front

Recommended

oil and capacity

: Refer to

.

ALDIA0503ZZ

JSDIA6402ZZ

JSDIA6403ZZ