содержание .. 1117 1118 1119 1120 ..

Nissan X-Trail 32. Manual - part 1119

ENGINE ASSEMBLY

EM-373

< UNIT REMOVAL AND INSTALLATION >

[R9M]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

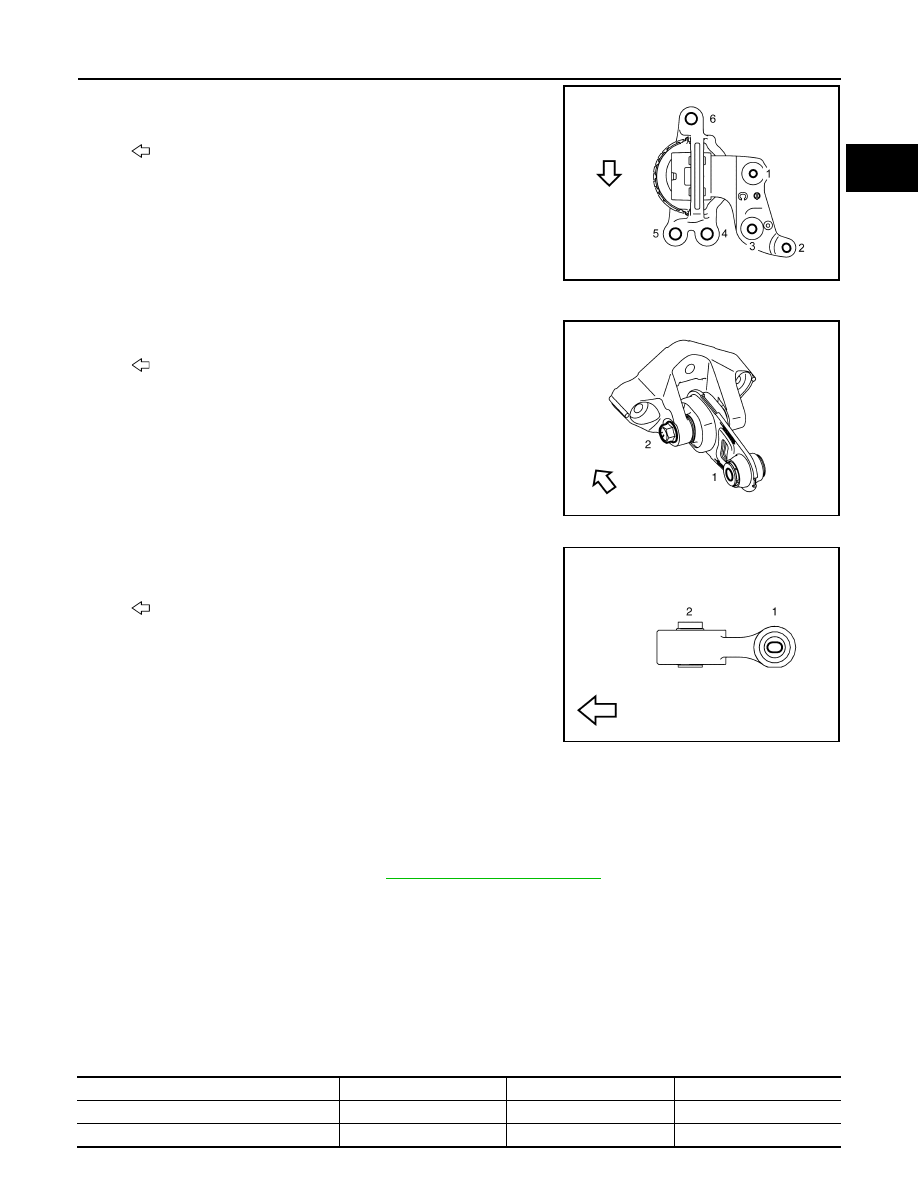

a.

Tighten the bolts in order of No. 1 to 3 as shown in the figure.

(specified torque)

b.

Tighten the bolts in order of No. 4 to 6 as shown in the figure

after removing the jack. (specified torque)

3.

Install the rear torque bolts as follows:

a.

Tighten the bolts as shown in the figure (specified torque).

4.

Install the upper torque rod bolt (RH).

• Tighten the bolts in order of No. 2 to 1 as shown in the figure.

(specified torque)

Inspection

INFOID:0000000010784355

INSPECTION AFTER INSTALLATION

Inspection for Leaks

• Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to

MA-23, "Fluids and Lubricants"

.

• Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gases, or any oil/fluids includ-

ing engine oil and engine coolant.

• Bleed air from lines and hoses of applicable lines, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

: Vehicle front

JPBIA6995ZZ

: Vehicle front

JPBIA6935ZZ

: Vehicle front

JSBIA4537ZZ

Items

Before starting engine

Engine running

After engine stopped

Engine coolant

Level

Leakage

Level

Engine oil

Level

Leakage

Level