содержание .. 1115 1116 1117 1118 ..

Nissan X-Trail 32. Manual - part 1117

ENGINE ASSEMBLY

EM-365

< UNIT REMOVAL AND INSTALLATION >

[R9M]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

UNIT REMOVAL AND INSTALLATION

ENGINE ASSEMBLY

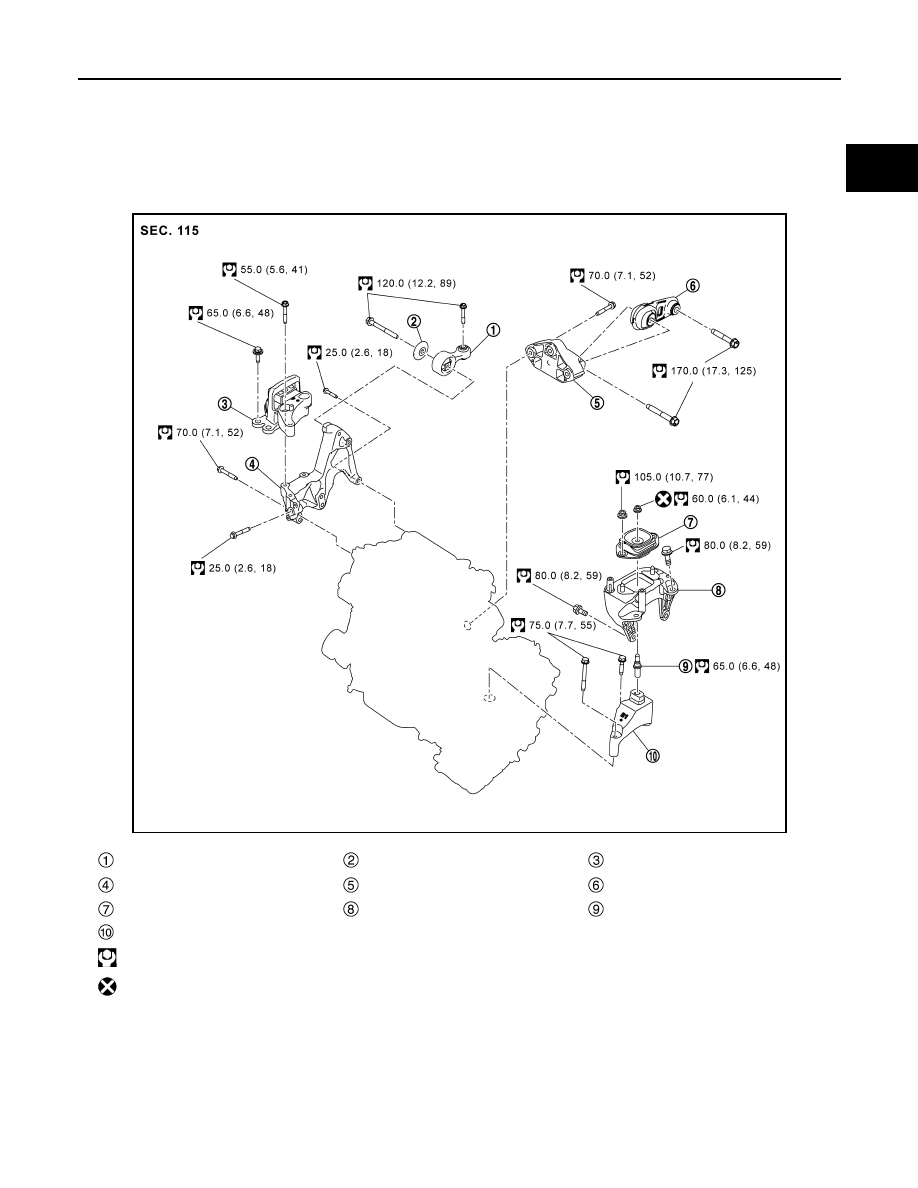

Exploded View

INFOID:0000000010784353

M/T models

JPBIA6927GB

Upper torque rod

Mass damper

Engine mounting insulator (RH)

Engine mounting bracket (RH)

Rear torque rod bracket

Rear torque rod

Engine mounting insulator (LH)

Engine mounting frame support (LH)

Stud bolt

Engine mounting bracket (LH)

: N·m (kg-m, ft-lb)

: Always replace after every disassembly.