содержание .. 109 110 111 112 ..

Nissan X-Trail 32. Manual - part 111

BR-38

< REMOVAL AND INSTALLATION >

[LHD]

BRAKE BOOSTER

CAUTION:

Never reuse brake fluid to drain.

• Check each item of brake pedal. Adjust it if the measurement value is not the standard. Refer to

.

Inspection and Adjustment

INFOID:0000000010838524

INSPECTION BEFORE REMOVAL

Air Tight

CAUTION:

Check the air tight condition when the master cylinder and the brake booster is installed.

1.

Check the air tight use a handy vacuum pump.

2.

If the air tight condition cannot be maintained, perform the following operation.

a.

Check the no dirt and dust are present on the brake booster and brake master cylinder mating faces.

Clean it if necessary.

b.

Check the O-ring on the master cylinder. If anything is found, replace the O-ring. Refer to

c.

Check the air tight condition again. If the condition still cannot be maintained, replace the brake booster.

INSPECTION AFTER REMOVAL

Check Valve Inspection

1.

Check the check valve to use a handy vacuum pump.

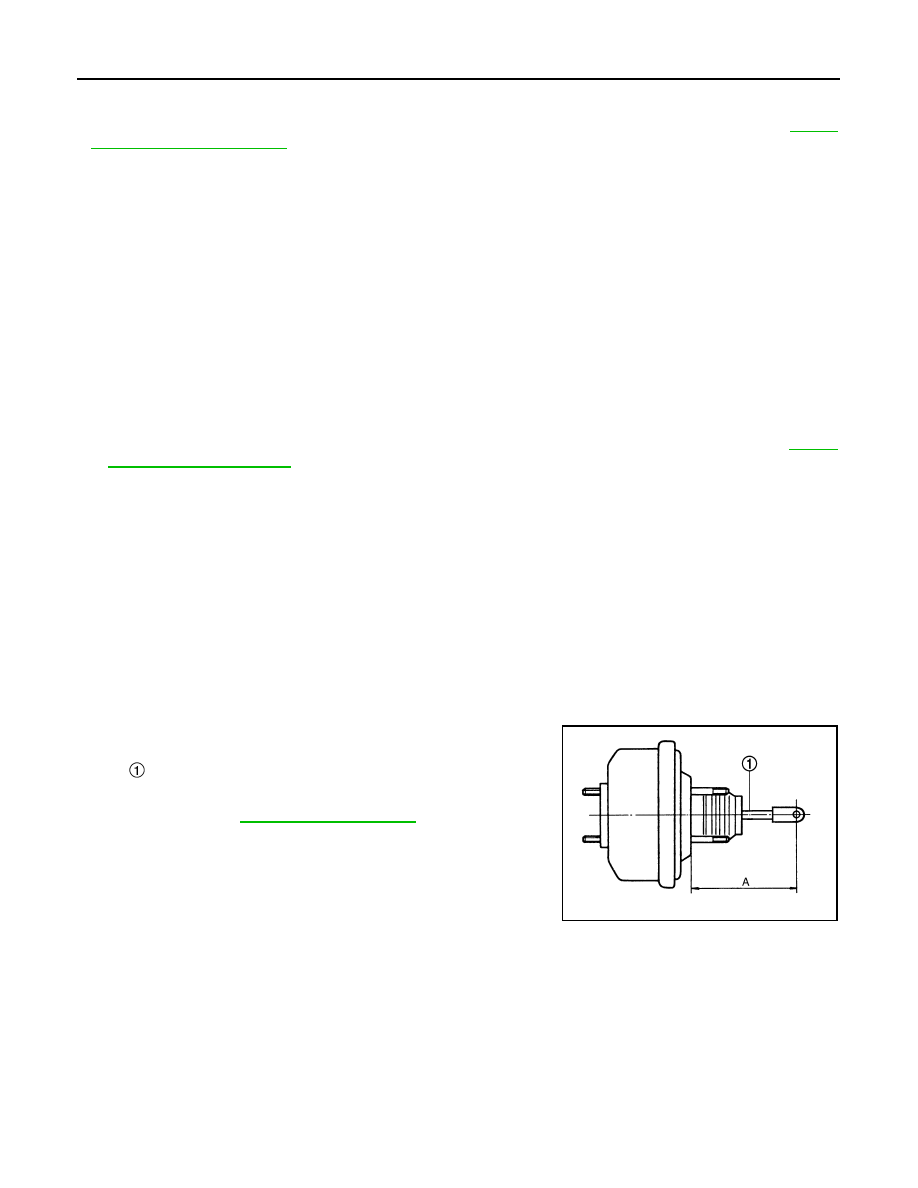

Input Rod Length rod Inspection

1.

Check the input length (A).

2.

Replace the brake booster if the input rod length is not the stan-

dard.

INSPECTION AFTER INSTALLATION

Operation

Depress the brake pedal several times at 5-second intervals with the engine stopped. Start the engine with the

brake pedal fully depressed. Check that the clearance between brake pedal and dash lower panel decreases.

NOTE:

A slight impact with a small click may be felt on the pedal when the brake pedal is fully depressed. this is nor-

mal phenomenon due to the brake system operation.

Air Tight

1.

Run the engine at idle for 1 minute to apply vacuum to the brake booster, and stop the engine.

At vacuum of

−

66.7 kPa (

−

500 mmHg,

−

19.69 inHg,

−

0.067 bar)

: Vacuum should decrease within 3.3 kPa (24.8 mmHg,

0.98 inHg, 0.033 bar) for 15 seconds.

In the case of connecting to brake

booster

: Vacuum should decrease within 3.3 kPa (24.8 mmHg,

0.98 inHg, 0.033 bar) for 15 seconds at vacuum of

−

66.7 kPa (

−

500 mmHg,

−

19.69 inHg,

−

0.067 bar).

In the case of connecting to vacuum

hose

: Vacuum should not exist.

:Input rod

A

: Refer to

.

JSFIA2251ZZ