содержание .. 108 109 110 111 ..

Nissan X-Trail 32. Manual - part 110

BR-34

< REMOVAL AND INSTALLATION >

[LHD]

BRAKE MASTER CYLINDER

• The piston

of the master cylinder assembly is exposed. Never

damage it when handling the master cylinder.

• Check that no dirt and dust are present on the piston before instal-

lation. Clean it with new brake fluid if necessary.

• The piston may drop off when pulled strongly. Never hold the pis-

ton. Hold the cylinder body when handling the master cylinder

assembly.

• Never deform or bend the brake tubes.

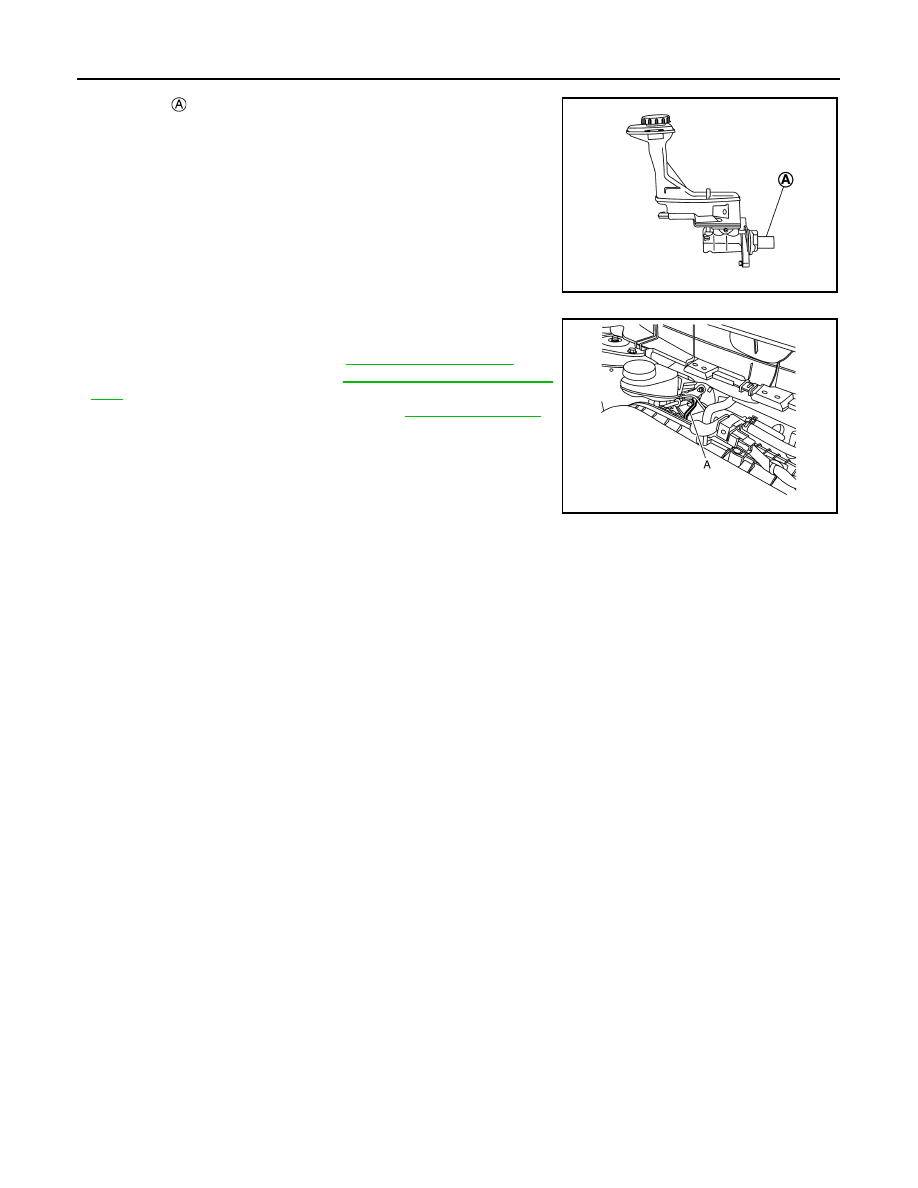

• Temporarily tighten the brake tube flare nut to the master cylinder

assembly by hand. Then tighten it to the specified torque with a

flare nut torque wrench (A). Refer to

• Perform the air bleeding. Refer to

• Perform inspection after installation. Refer to

Disassembly and Assembly

INFOID:0000000010838520

DISASSEMBLY

CAUTION:

• Never disassemble the cylinder body.

• Remove the reservoir tank only when necessary.

• Never drop parts to remove. Replace new parts when dropping.

1.

Fix the master cylinder assembly to a vise.

CAUTION:

• Always set copper plates or cloth between vise grips when fixing the cylinder body to a vise.

• Never overtighten the vise.

2.

Remove the reservoir tank mounting screw.

3.

Remove the reservoir tank and grommet from the cylinder body.

ASSEMBLY

CAUTION:

• Never use mineral oils such as kerosene or gasoline and rubber grease during the cleaning and

assembly process.

• Never allow foreign matter (e.g. dust) and oils other than brake fluid to enter the reservoir tank.

• Never drop when installing. The parts must not be reused if they are dropped.

1.

Apply new brake fluid to the grommet and install it to the cylinder body.

CAUTION:

Never reuse grommets.

2.

Install the reservoir tank to the cylinder body.

3.

Fix the cylinder body to a vise.

CAUTION:

JSFIA2382ZZ

JSFIA2238ZZ