содержание .. 1086 1087 1088 1089 ..

Nissan X-Trail 32. Manual - part 1088

CYLINDER BLOCK

EM-249

< UNIT DISASSEMBLY AND ASSEMBLY >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

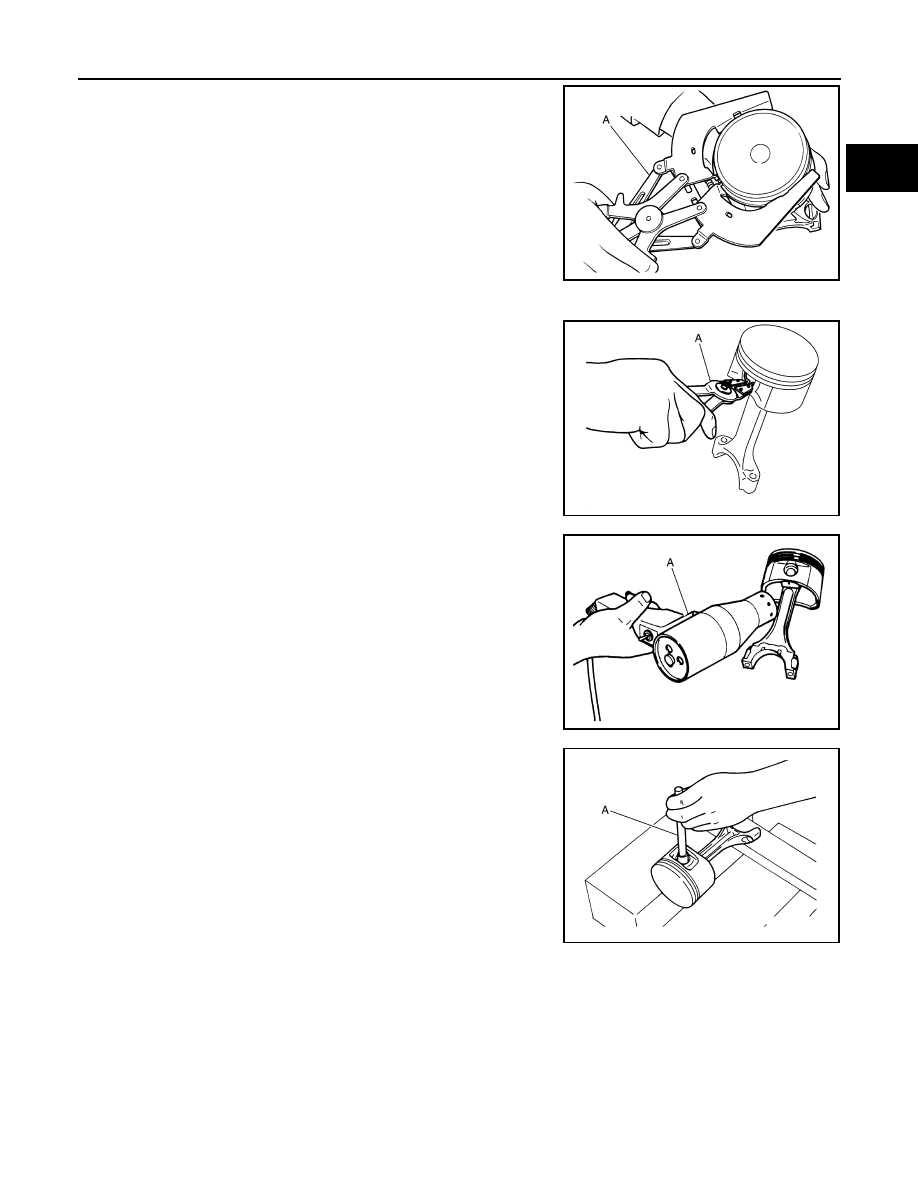

• Use a piston ring expander (commercial service tool) (A).

CAUTION:

• When removing piston rings, be careful not to damage

the piston.

• Be careful not to damage piston rings by expanding

them excessively.

7.

Remove piston from connecting rod with the following procedure:

a.

Using snap ring pliers (A), remove snap ring.

b.

Heat piston to 60 to 70

°

C (140 to 158

°

F) with an industrial use

drier (A) or equivalent.

c.

Push out piston pin with stick (A) of outer diameter approxi-

mately 19 mm (0.75 in).

8.

Remove lower cylinder block mounting bolts.

JSBIA2493ZZ

JSBIA2494ZZ

JSBIA2495ZZ

JSBIA2496ZZ