содержание .. 1085 1086 1087 1088 ..

Nissan X-Trail 32. Manual - part 1087

OIL PAN (UPPER) AND OIL STRAINER

EM-245

< UNIT DISASSEMBLY AND ASSEMBLY >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

b.

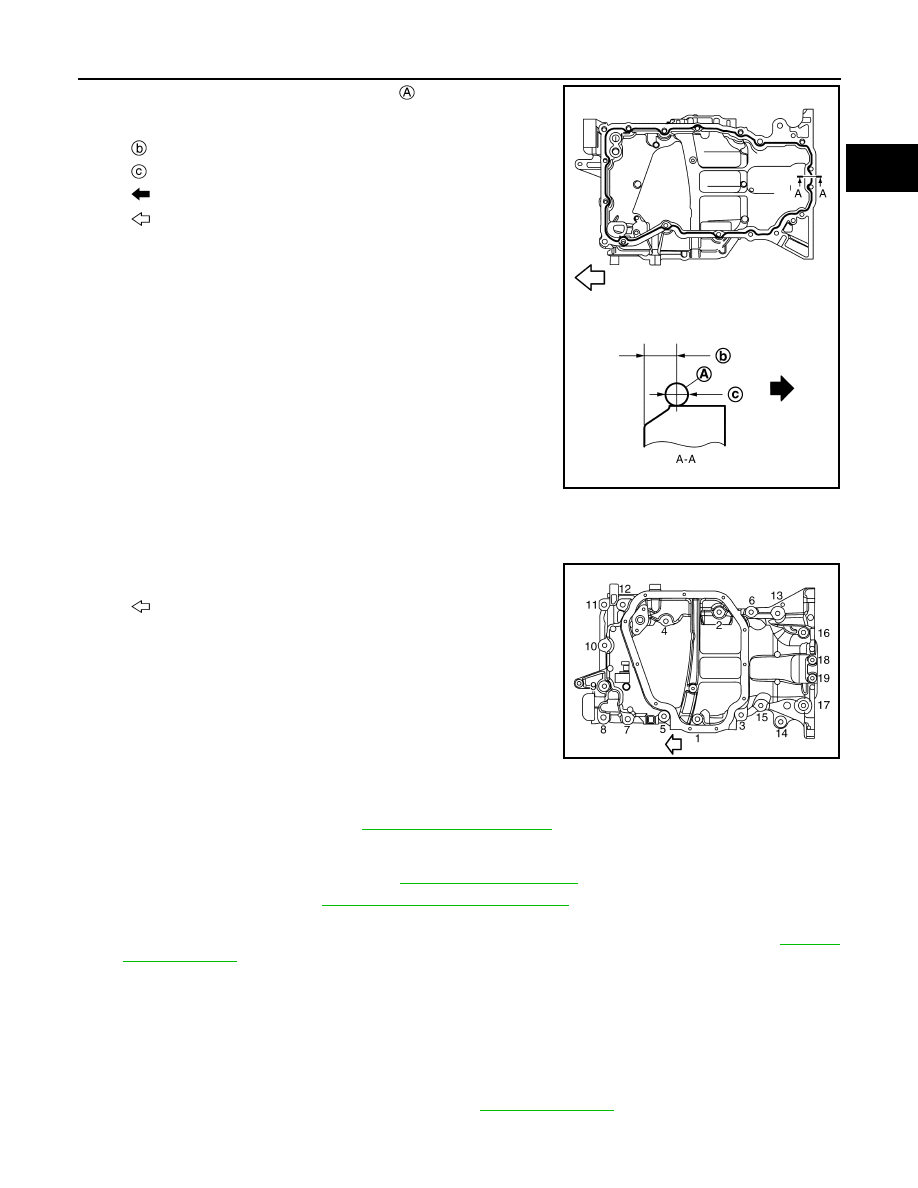

Apply a continuous bead of liquid gasket

with a tube presser

(commercial service tool) as shown in the figure.

Use Genuine Liquid Gasket or equivalent.

CAUTION:

• Attaching should be done within 5 minutes after liquid

gasket application.

c.

Install new O-rings at front cover side.

CAUTION:

Do not reuse O-rings.

d.

Tighten bolts in numerical order as shown in the figure.

NOTE:

Refer to the following for locating bolts.

2.

Install oil strainer.

3.

Install front suspension member. Refer to

4.

Install oil pan (lower). Refer to

EM-194, "Removal and Installation"

5.

Install oil pan drain plug.

• Refer to the figure of components of former page for installation direction of washer. Refer to

.

6.

Install in the reverse order of removal after this step.

NOTE:

Pour engine oil at least 30 minutes after oil pan is installed.

Inspection

INFOID:0000000010783821

INSPECTION AFTER INSTALLATION

1.

Check engine oil level and adjust engine oil. Refer to

.

2.

Start engine, and check there is no leaks of engine oil.

: 5.5 - 7.5mm (0.216 - 0.295 in)

:

φ

4.0 - 5.0 mm (0.157 - 0.197 in)

: Engine outside

: Engine front

JSBIA3338ZZ

: Engine front

M6

×

22 mm (0.87 in)

: No. 18, 19

M8

×

27 mm (1.06 in)

: No. 2, 4, 6, 11, 15, 16, 17

M8

×

58 mm (2.28 in)

: No. 7, 8, 9, 10

M8

×

77 mm (3.03 in)

: No. 1, 3, 5, 12

M8

×

100 mm (3.94 in)

: No. 13, 14

Tightening torque

JSBIA3337ZZ