содержание .. 1087 1088 1089 1090 ..

Nissan X-Trail 32. Manual - part 1089

CYLINDER BLOCK

EM-253

< UNIT DISASSEMBLY AND ASSEMBLY >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

ii.

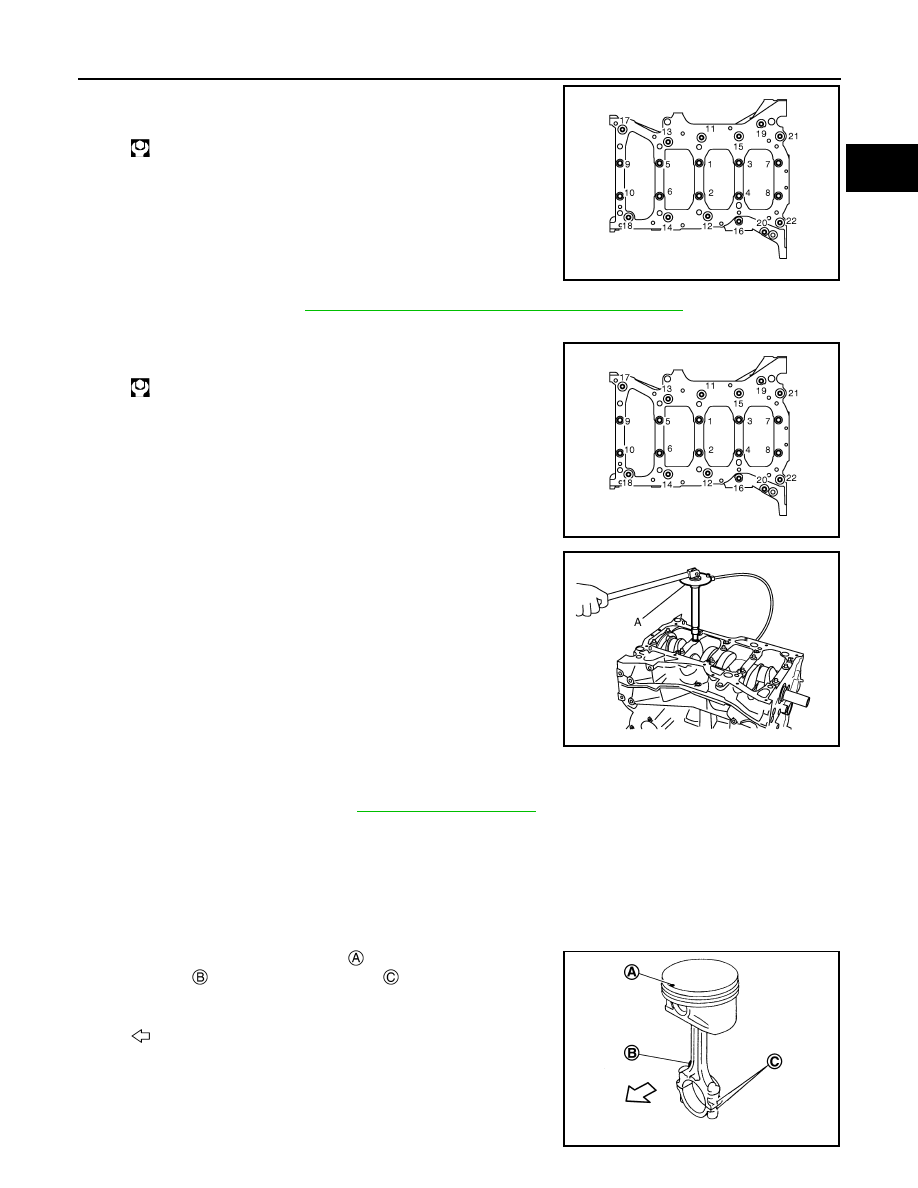

Tighten M8 bolts in numerical order from No. 11 to 22 in the fig-

ure.

NOTE:

There are more processes to complete the tightening of mount-

ing bolts. However stop procedure here to install rear oil seal.

c.

Install rear oil seal. Refer to

EM-198, "REAR OIL SEAL : Removal and Installation"

d.

Restart tightening of lower cylinder block mounting bolts with the following procedure:

i.

Tighten M10 bolts in numerical order from No. 1 to 10.

ii.

Turn M10 bolts 60 degrees clockwise (angle tightening) in order

from No. 1 to 10 in the figure.

CAUTION:

Check and confirm the tightening angle by using an angle

wrench [SST: KV10112100] (A) or protractor. Avoid judg-

ment by visual inspection without the tool.

• After installing mounting bolts, check that crankshaft can be rotated smoothly by hand.

• Wipe off completely any protruding liquid gasket on front side of engine.

• Check the crankshaft end play.refer to

8.

Install piston to connecting rod with the following procedure:

a.

Using snap ring pliers, install new snap ring to the groove of the piston rear side.

• Insert it fully into groove to install.

b.

Assemble piston to connecting rod.

• Using an industrial drier or similar tool, heat piston until piston pin can be pushed in by hand without

excess force [approximately 60 to 70

°

C (140 to 158

°

F)]. From the front to the rear, insert piston pin into

piston and connecting rod.

• Assemble so that the front mark

on the piston head and the

oil splash

and the cylinder number

on connecting rod are

positioned as shown in the figure.

c.

Install new snap ring to the groove of the piston front side.

• Insert it fully into groove to install.

• After installing, check that connecting rod moves smoothly.

: 25.1 N·m (2.6 kg-m, 19 ft-lb)

JPBIA0904ZZ

: 39.2 N·m (4.0 kg-m, 29 ft-lb)

JPBIA0904ZZ

JPBIA0687ZZ

: Engine front

JSBIA3397ZZ