Qashqai J11. Engine control system (MR20DD) - part 17

ECM-258

< DTC/CIRCUIT DIAGNOSIS >

[MR20DD]

P0327, P0328 KS

2.

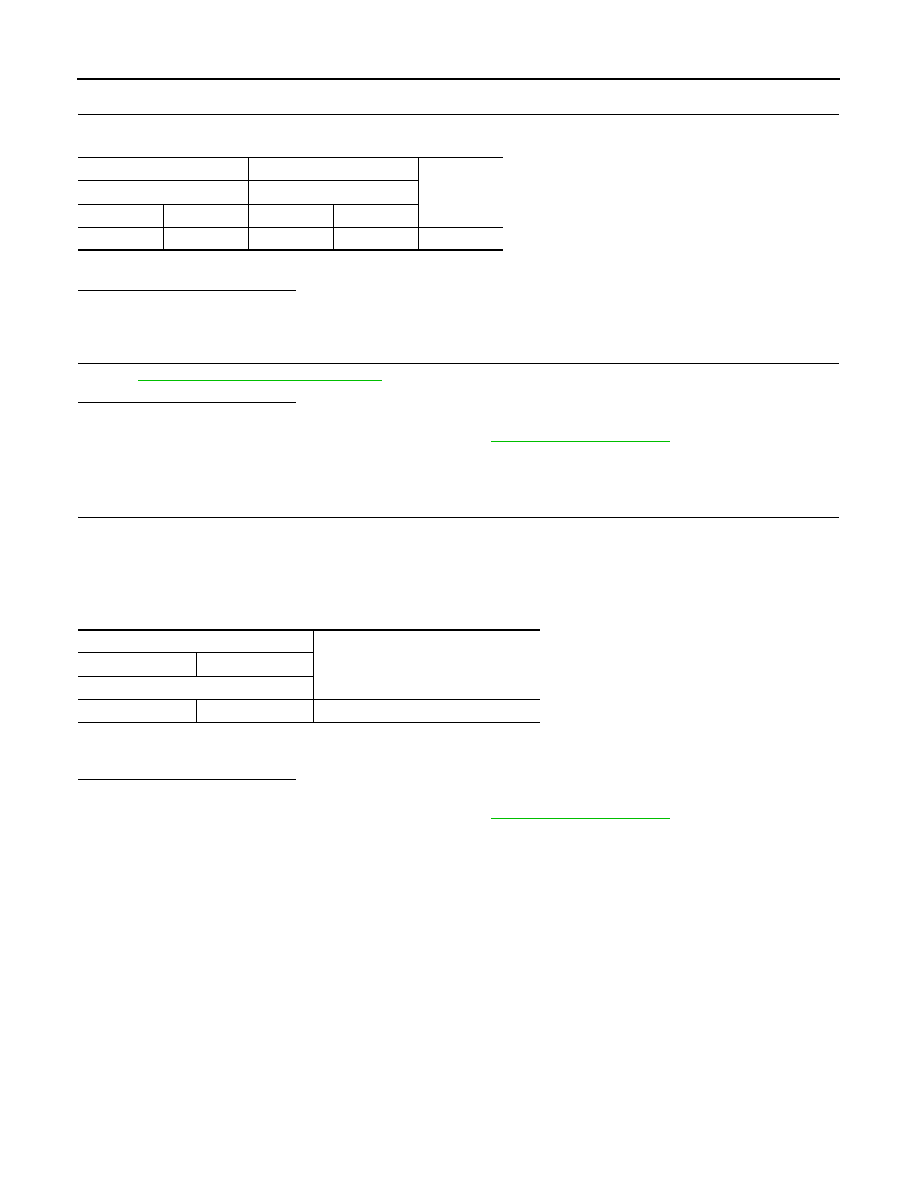

CHECK KNOCK SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1.

Check the continuity between knock sensor harness connector and ECM harness connector.

2.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair or replace malfunctioning part.

3.

CHECK KNOCK SENSOR

ECM-258, "Component Inspection"

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace malfunctioning knock sensor. Refer to

Component Inspection

INFOID:0000000010702957

1.

CHECK KNOCK SENSOR

1.

Turn ignition switch OFF.

2.

Disconnect knock sensor harness connector.

3.

Check resistance between knock sensor terminals as follows.

NOTE:

It is necessary to use an ohmmeter which can measure more than 10 M

Ω

.

CAUTION:

Do not use any knock sensors that have been dropped or physically damaged. Use only new ones.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace malfunctioning knock sensor. Refer to

+

−

Continuity

Knock sensor

ECM

Connector

Terminal

Connector

Terminal

F153

1

F15

40

Existed

Knock sensor

Resistance

+

−

Terminal

1

2

Approx. 532 - 588 k

Ω

[at 20

°

C (68

°

F)]