Qashqai J11. Engine control system (K9K) - part 16

P0409 EGR VOLUME CONTROL VALVE POSITION SENSOR

ECK-241

< DTC/CIRCUIT DIAGNOSIS >

[K9K]

C

D

E

F

G

H

I

J

K

L

M

A

ECK

N

P

O

2.

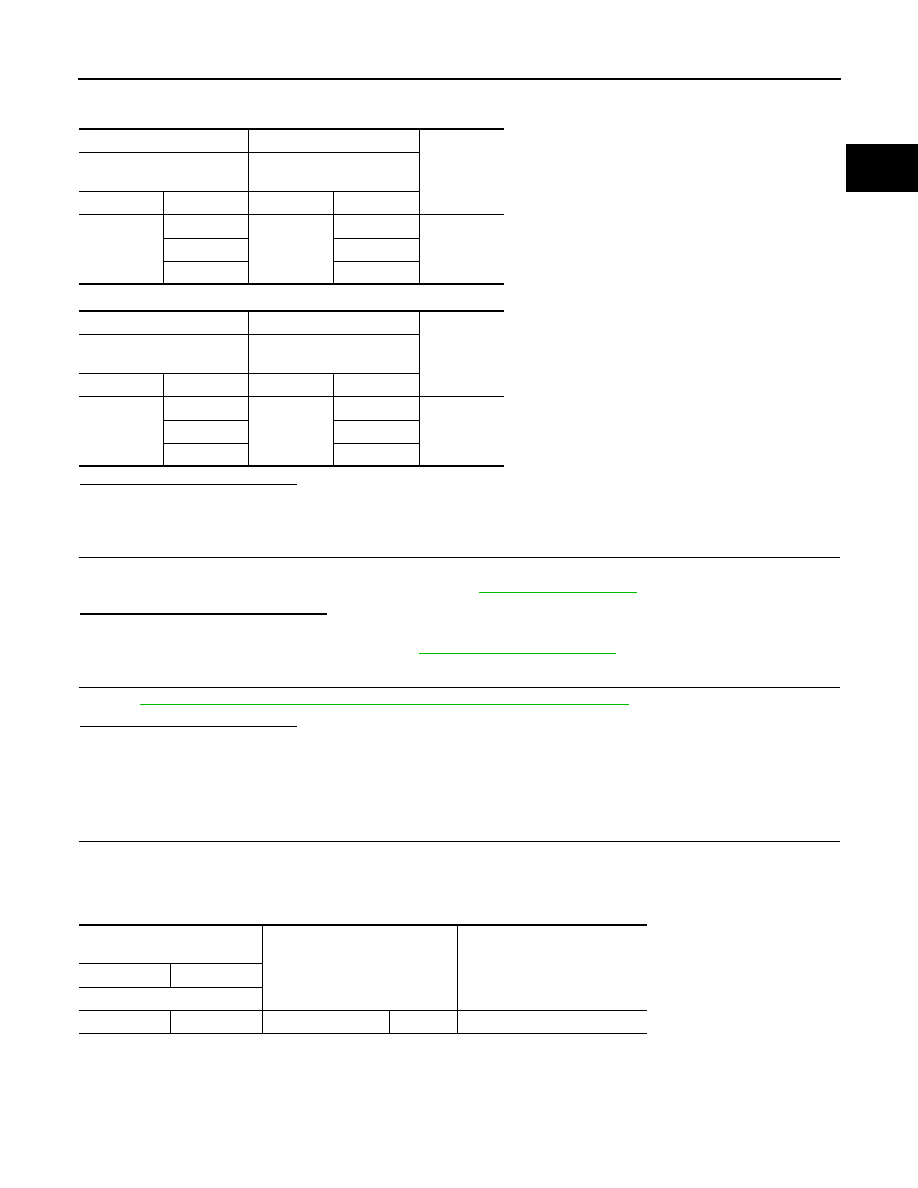

Check low pressure EGR valve and high pressure EGR valve position sensor circuit for open and short.

HIGH PRESSURE EGR VOLUME CONTROL VALVE

LOW PRESSURE EGR VOLUME CONTROL VALVE

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair or replace error-detected parts.

5.

DTC CONFIRMATION PROCEDURE

1.

Erase DTC.

2.

Perform DTC confirmation procedure again. Refer to

Is the DTC P0409 displayed again?

YES

>> GO TO 6.

NO

>> Check intermittent incident. Refer to

GI-41, "Intermittent Incident"

.

6.

CHECK LOW PRESSURE EGR VALVE MOTOR AND HIGH PRESSURE EGR VALVE MOTOR

ECK-241, "Component Inspection (EGR Volume Control Valve Motor)"

Is the inspection result normal?

YES

>> Replace high pressure EGR valve position sensor and low pressure EGR valve position sensor.

NO

>> Replace error-detected parts.

Component Inspection (EGR Volume Control Valve Motor)

INFOID:0000000010289829

1.

CHECK LOW PRESSURE EGR VALVE MOTOR AND HIGH PRESSURE EGR VALVE MOTOR

1.

Turn ignition switch OFF.

2.

Disconnect low pressure EGR valve and high pressure EGR valve harness connector.

3.

Check resistance between low pressure EGR valve and high pressure EGR valve terminals as follows.

HIGH PRESSURE EGR VOLUME CONTROL VALVE

+

-

Continuity

ECM

High pressure EGR volume

control valve

Connector

Terminal

Connector

Terminal

F80

69

F60

6

Existed

70

3

75

1

+

-

Continuity

ECM

Low pressure EGR volume

control valve

Connector

Terminal

Connector

Terminal

F80

65

F34

1

Existed

66

2

79

3

High pressure EGR volume

control valve

Condition

Resistance (Approx.)

+

-

Terminal

2

5

Temperature

°

C (

°

F)

23 (73)

2.4

Ω