Qashqai J11. Engine control system (K9K) - part 15

P025B FUEL PUMP CONTROL MODULE CONTROL

ECK-225

< DTC/CIRCUIT DIAGNOSIS >

[K9K]

C

D

E

F

G

H

I

J

K

L

M

A

ECK

N

P

O

P025B FUEL PUMP CONTROL MODULE CONTROL

DTC Logic

INFOID:0000000010434254

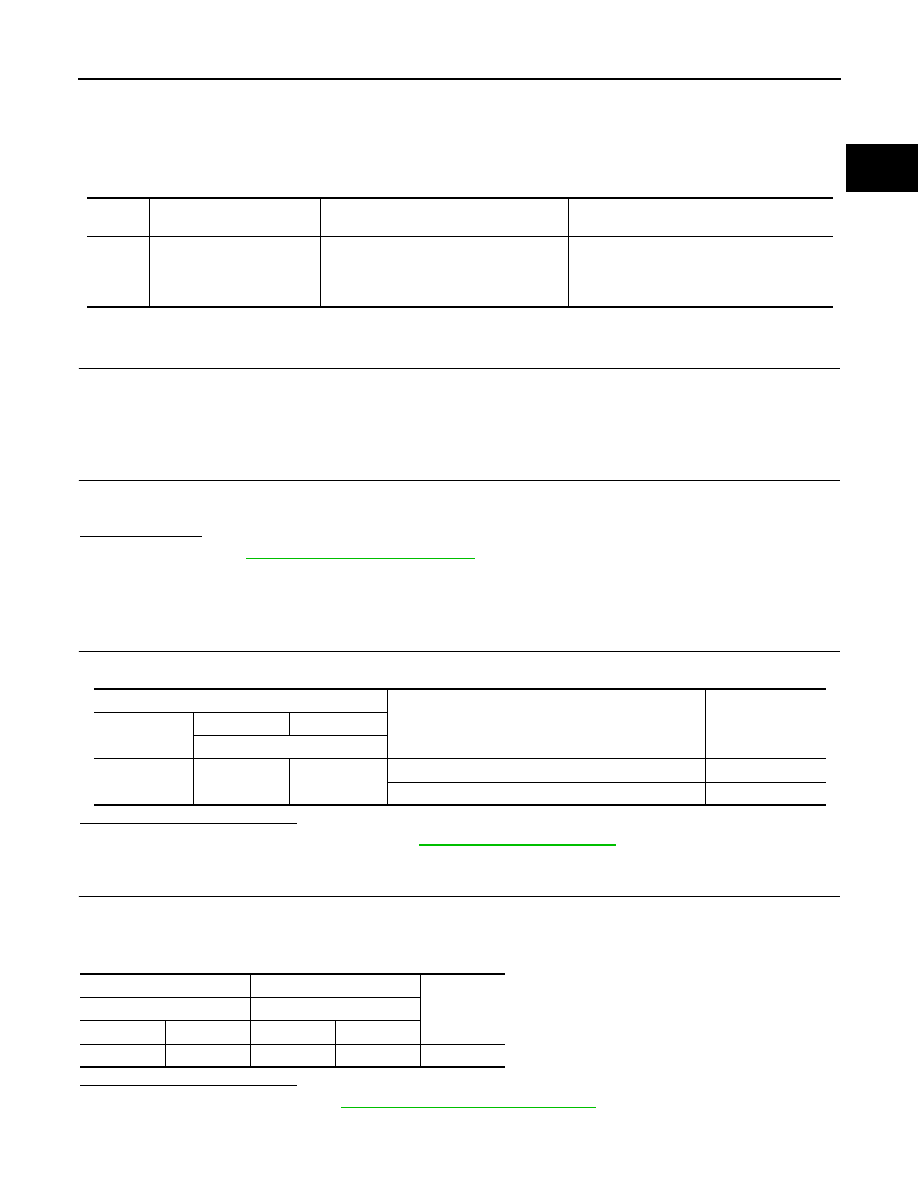

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 1 minute before conducting the next test.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

1.

Turn ignition switch ON and wait at least 1 second.

2.

Check DTC.

Is DTC detected?

YES

>> Proceed to

ECK-225, "Diagnosis Procedure"

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000010434255

1.

CHECK COMMAND VOLTAGE

Check FPCM command voltage as the following conditions.

Is the inspection result normal?

YES

>> Check intermittent incident. Refer to

GI-41, "Intermittent Incident"

.

NO

>> GO TO 2.

2.

CHECK FUEL PUMP CONTROL MODULE COMMAND CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector and FPCM harness connector.

3.

Check the continuity between ECM harness connector and FPCM harness connector.

Is the inspection result normal?

YES

>> Replace FPCM. Refer to

ECK-404, "Removal and Installation"

NO

>> Repair or replace error-detected parts.

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P025B

FUEL PUMP MODULE

CONTROL CIRCUIT

(Fuel pump module control

circuit range/performance)

• FPCM command circuit is open or short-

ed.

• ECU temperature is too high.

• Harness or connectors

(FPCM command circuit is open or short-

ed.)

• FPCM

ECM

Condition

Voltage

Connector

+

–

Terminal

E59

13

29

Ignition switch: OFF

⇒

ON (fuel pump activated)

0 – 6.74 V

Ignition switch ON (fuel pump not activated)

0.05 V

+

−

Continuity

ECM

FPCM

Connector

Terminal

Connector

Terminal

E59

13

B77

9

Existed