Qashqai J11. Engine control system (K9K) - part 14

P0190 FRP SENSOR

ECK-209

< DTC/CIRCUIT DIAGNOSIS >

[K9K]

C

D

E

F

G

H

I

J

K

L

M

A

ECK

N

P

O

P0190 FRP SENSOR

DTC Logic

INFOID:0000000010289793

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PERFORM DIAGNOSIS PROCEDURE

NOTE:

DTC P0190 can not duplicate.

>> Proceed to

ECK-209, "Diagnosis Procedure"

Diagnosis Procedure

INFOID:0000000010289794

1.

CHECK ECM HARNESS CONNECTOR CONNECTIONS

1.

Turn ignition switch OFF.

2.

Check ECM harness connector connection F80.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace error-detected parts.

2.

CHECK FUEL RAIL PRESSURE SENSOR HARNESS CONNECTOR CONNECTIONS

Check fuel rail pressure sensor harness connector connection F40.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair or replace error-detected parts.

3.

CHECK FUEL PIPING

Check fuel hoses and fuel tubes for clogging.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair or replace error-detected parts.

4.

CHECK FUEL RAIL PRESSURE SENSOR POWER SUPPLY CIRCUIT

1.

Turn ignition switch ON.

2.

Check the power supply of the fuel rail pressure sensor.

Is the inspection result normal?

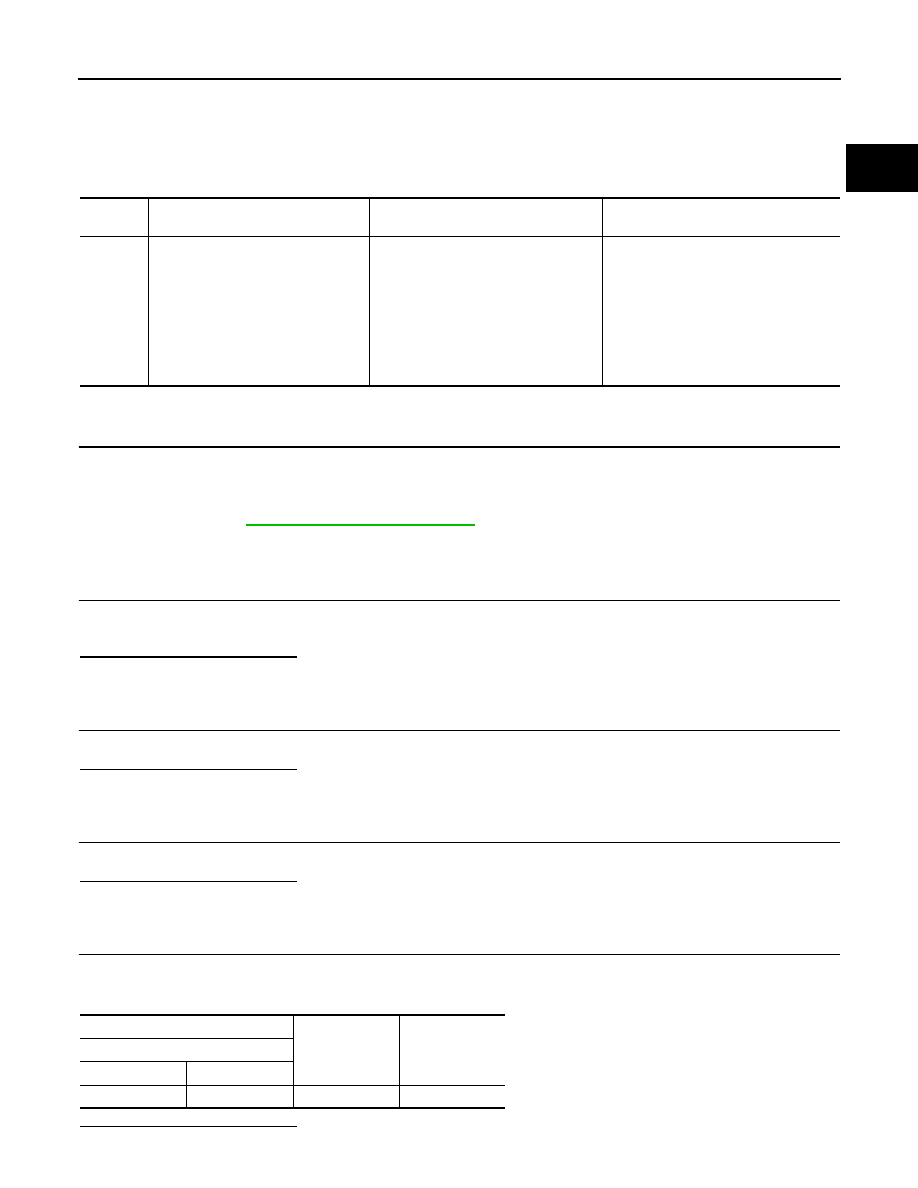

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0190

RAIL PRESSURE SENSOR CIR-

CUIT

(Fuel rail pressure sensor “A” circuit)

• 1.DEF: VOLTAGE TOO LOW

• 2.DEF: VOLTAGE TOO HIGH

• 3.DEF: ABOVE THE MAX LEVEL

• 4.DEF: SIGNAL INCOHERENCE

• 5.DEF: INTERMITTENT SIGNAL

INCOHERENCE

• An excessively low voltage from the

sensor is sent to ECM.

• An excessively high voltage from the

sensor is sent to ECM.

• An improper voltage signal from sen-

sor is sent to ECM.

• Harness or connectors

(Fuel rail pressure sensor circuit is

open or shorted.)

• Fuel rail pressure sensor

• ECM

+

-

Voltage

(Approx.)

Fuel rail pressure sensor

Connector

Terminal

F40

3

Ground

5.0 V