Nissan Qashqai J11. Manual - part 851

REAR DRIVE SHAFT

RAX-15

< REMOVAL AND INSTALLATION >

[4WD]

C

E

F

G

H

I

J

K

L

M

A

B

RAX

N

O

P

3.

Remove disc rotor.

4.

Remove cotter pin, then loosen hub lock nut.

5.

Patch hub lock nut with a piece of wood. Hammer the wood to

disengage wheel hub and bearing assembly from drive shaft.

Remove the hub lock nut.

CAUTION:

• Never place drive shaft joint at an extreme angle. Also be

careful not to overextend slide joint.

• Never allow drive shaft to hang down without support for

housing (or joint sub-assembly), shaft and the other parts.

NOTE:

Using a suitable puller if the wheel hub and bearing assembly

and drive shaft cannot be separated even after performing the

above procedure.

6.

Remove wheel sensor from axle housing. Refer to

BRC-139, "REAR WHEEL SENSOR : Exploded

.

7.

Remove stabilizer link. Refer to

8.

Set suitable jack under suspension arm.

9.

Remove shock absorber from suspension arm. Refer to

10. Remove upper link from suspension arm. Refer to

11. Remove lower link from suspension arm. Refer to

.

12. Remove drive shaft from final drive assembly.

INSTALLATION

Note the following, and install in the reverse order of removal.

• Perform final tightening of bolts and nuts at suspension arm (rubber bushing), under unladen conditions with

tires on level ground.

Disassembly and Assembly

INFOID:0000000010297914

DISASSEMBLY

Final Drive Side

1.

Fix shaft with a vise.

CAUTION:

Protect shaft using aluminum or copper plates when fixing with a vise.

2.

Remove boot bands, and then remove boot from housing.

3.

Put matching marks on housing and shaft.

CAUTION:

Use paint or an equivalent for matching marks. Never scratch the surface.

4.

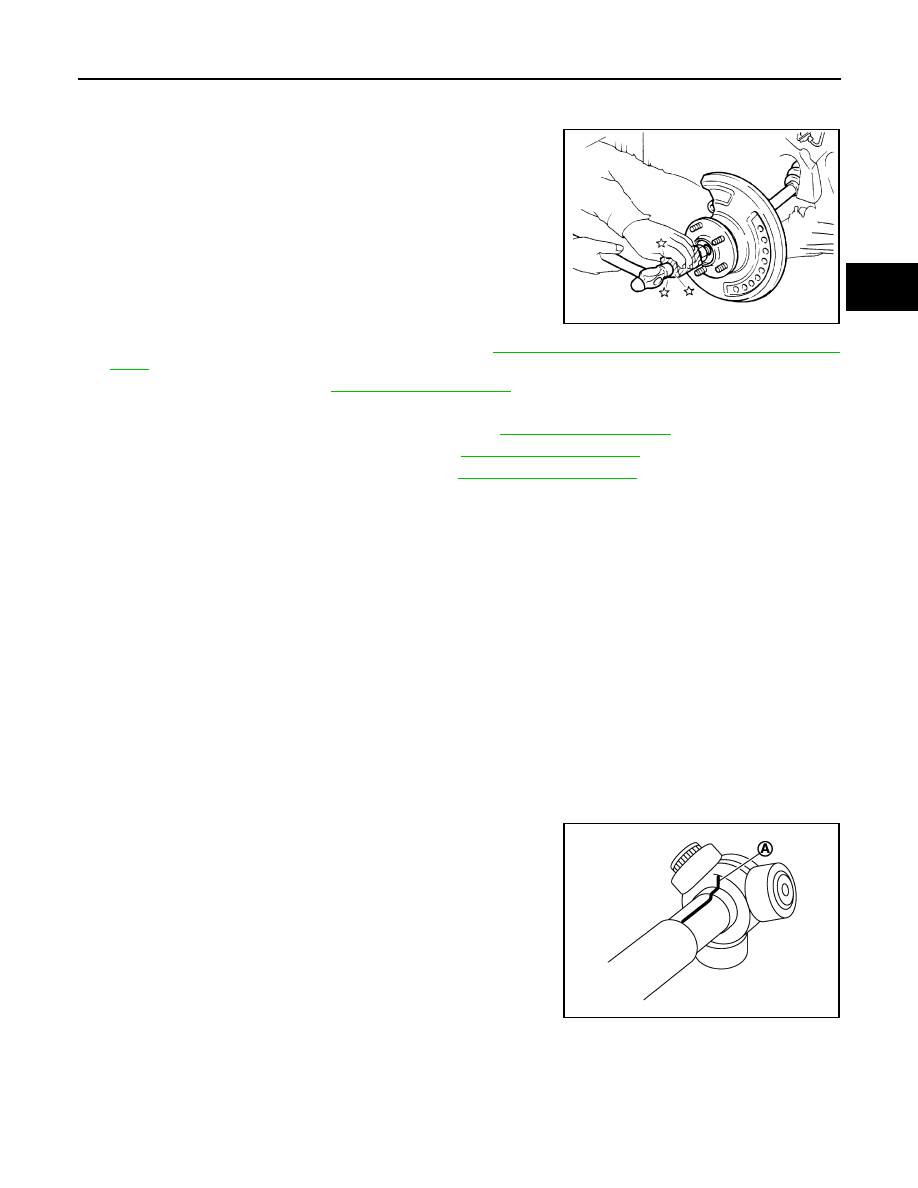

Put matching marks (A) on the spider assembly and shaft.

CAUTION:

Use paint or an equivalent for matching marks. Never

scratch the surface.

JPDIF0003ZZ

JPDIF0006ZZ