Nissan Qashqai J11. Manual - part 849

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

RAX-7

< SYMPTOM DIAGNOSIS >

[4WD]

C

E

F

G

H

I

J

K

L

M

A

B

RAX

N

O

P

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

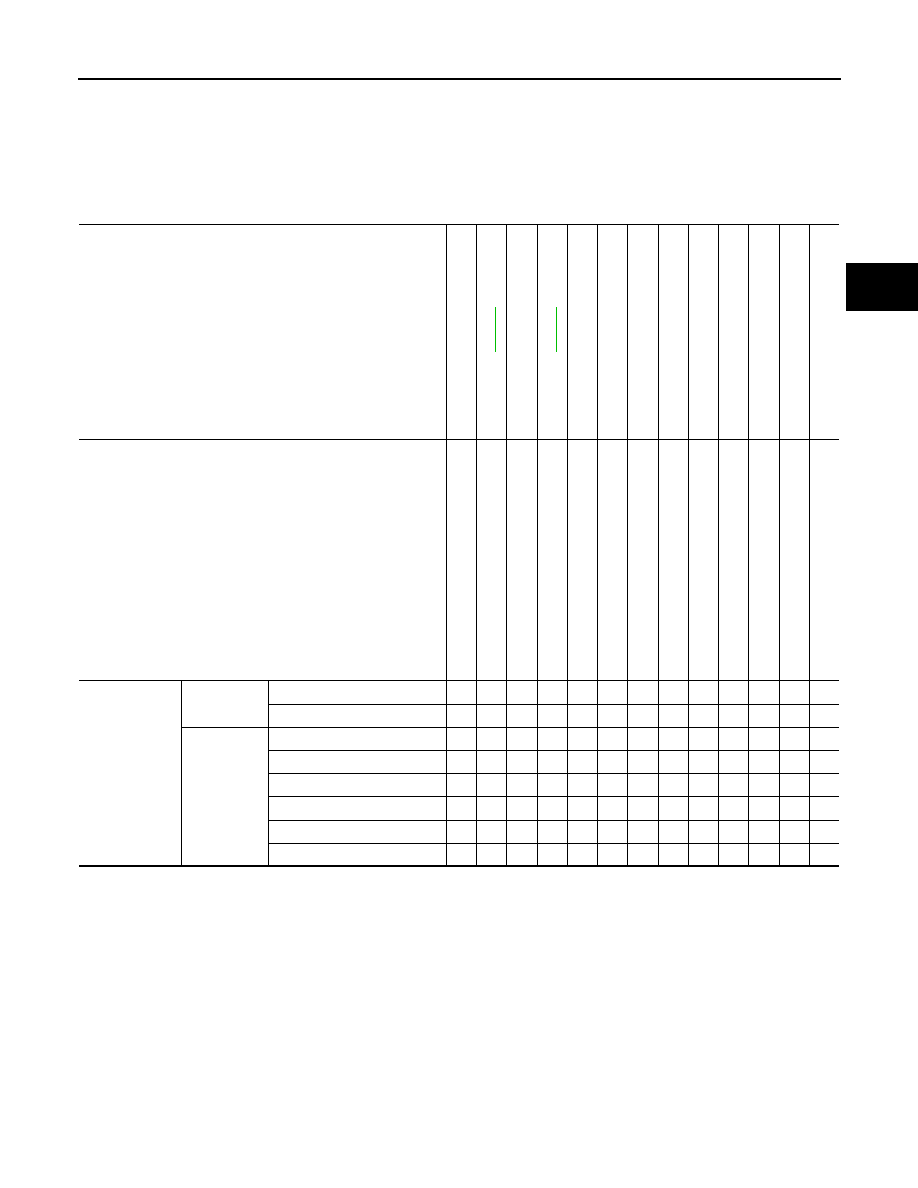

NVH Troubleshooting Chart

INFOID:0000000010297903

Use chart below you find the cause of the symptom. If necessary, repair or replace these parts.

×

: Applicable

Reference page

—

—

—

NVH in DLN section

NVH in DLN section

NVH in RAX

and RSU

sections

Refer to REAR AXLE i

n

t

h

is chart

NVH in WT

section

NVH in WT

section

Ref

e

r t

o

DRIVE

SHAFT

in this

chart

NVH in BR

section

Possible cause and SUSPECTED PARTS

Ex

ce

ss

iv

e j

o

in

t an

gl

e

Jo

in

t s

lid

in

g re

si

st

an

ce

Im

b

a

lanc

e

Im

p

rop

er i

n

s

ta

lla

tio

n

,

loo

s

en

es

s

P

a

rt

s interference

PR

OP

EL

LE

R

S

H

A

F

T

DIFFERENTIAL

REA

R

AXLE AND REAR S

U

SPENSION

REA

R

AXLE

TI

RE

ROAD W

H

EEL

DRIV

E

SHAFT

BR

AK

E

Symptom

DRIVE

SHAFT

Noise

×

×

×

×

×

×

×

×

×

Shake

×

×

×

×

×

×

×

×

REAR AXLE

Noise

×

×

×

×

×

×

×

×

×

Shake

×

×

×

×

×

×

×

×

Vibration

×

×

×

×

×

×

Shimmy

×

×

×

×

×

×

Judder

×

×

×

×

×

Poor quality ride or handling

×

×

×

×

×