Nissan Juke F15. Manual - part 787

FRONT DRIVE SHAFT

FAX-87

< REMOVAL AND INSTALLATION >

[TYPE 2]

C

E

F

G

H

I

J

K

L

M

A

B

FAX

N

O

P

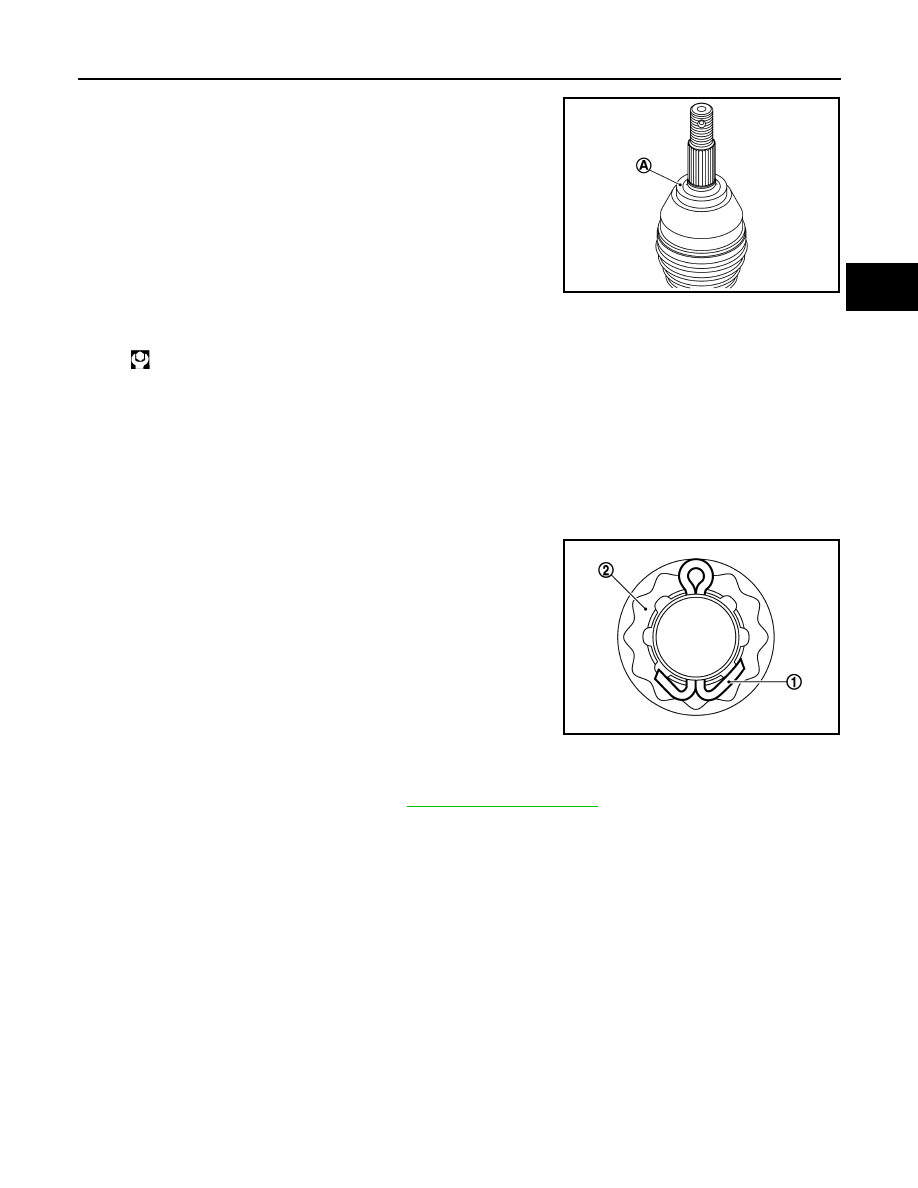

• Clean the matching surface of drive shaft and wheel hub assembly.

And then apply paste [service parts (440037S000)] to surface (A)

of joint sub-assembly of drive shaft.

CAUTION:

Apply paste to cover entire flat surface of joint sub-assembly

of drive shaft.

• Use the following torque range for tightening the wheel hub lock nut.

CAUTION:

• Since the drive shaft is assembled by press-fitting, use the tightening torque range for the wheel

hub lock nut.

• Be sure to use torque wrench to tighten the wheel hub lock nut. Never use a power tool.

• Never reuse wheel hub lock nut.

NOTE:

Wheel hub lock nut tightening torque does not over torque for avoiding axle noise, and does not less than

torque for avoiding looseness.

• Align the matching marks that have been made during removal when reusing the disc rotor.

• When installing a cotter pin (1) and adjusting cap (2), securely

bend the basal portion to prevent rattles.

CAUTION:

Never reuse cotter pin.

• Perform the final tightening of each of parts under unladen conditions, which were removed when removing

wheel hub assembly and steering knuckle.

• Perform inspection after installation. Refer to

.

2WD : Disassembly and Assembly

INFOID:0000000012201562

DISASSEMBLY

Wheel Side

1. Fix shaft with a vise.

CAUTION:

Protect shaft using aluminum or copper plates when fixing with a vise.

2. Remove boot bands, and then remove boot from joint sub-assembly.

Amount paste

: 1.0 – 3.0 g (0.04 – 0.10 oz)

JSDIA2844ZZ

: 180 – 185 N·m (18.4 – 18.8 kg-m, 133 – 136 ft-lb)

JPDIF0295ZZ