Nissan Juke F15. Manual - part 786

FRONT DRIVE SHAFT

FAX-83

< REMOVAL AND INSTALLATION >

[TYPE 2]

C

E

F

G

H

I

J

K

L

M

A

B

FAX

N

O

P

2WD : Removal and Installation

INFOID:0000000012201561

REMOVAL

Left Side

1. Remove tires with power tool. Refer to

WT-39, "Removal and Installation"

.

2. Remove wheel sensor and sensor harness. Refer to

BRC-147, "FRONT WHEEL SENSOR : Exploded

.

3. Remove lock plate from strut assembly. Refer to

BR-25, "FRONT : Removal and Installation"

.

4. Remove caliper assembly. Hang caliper assembly not to interfere with work. Refer to

CALIPER ASSEMBLY : Removal and Installation"

.

CAUTION:

Never depress brake pedal while brake caliper is removed.

5. Remove disc rotor.

CAUTION:

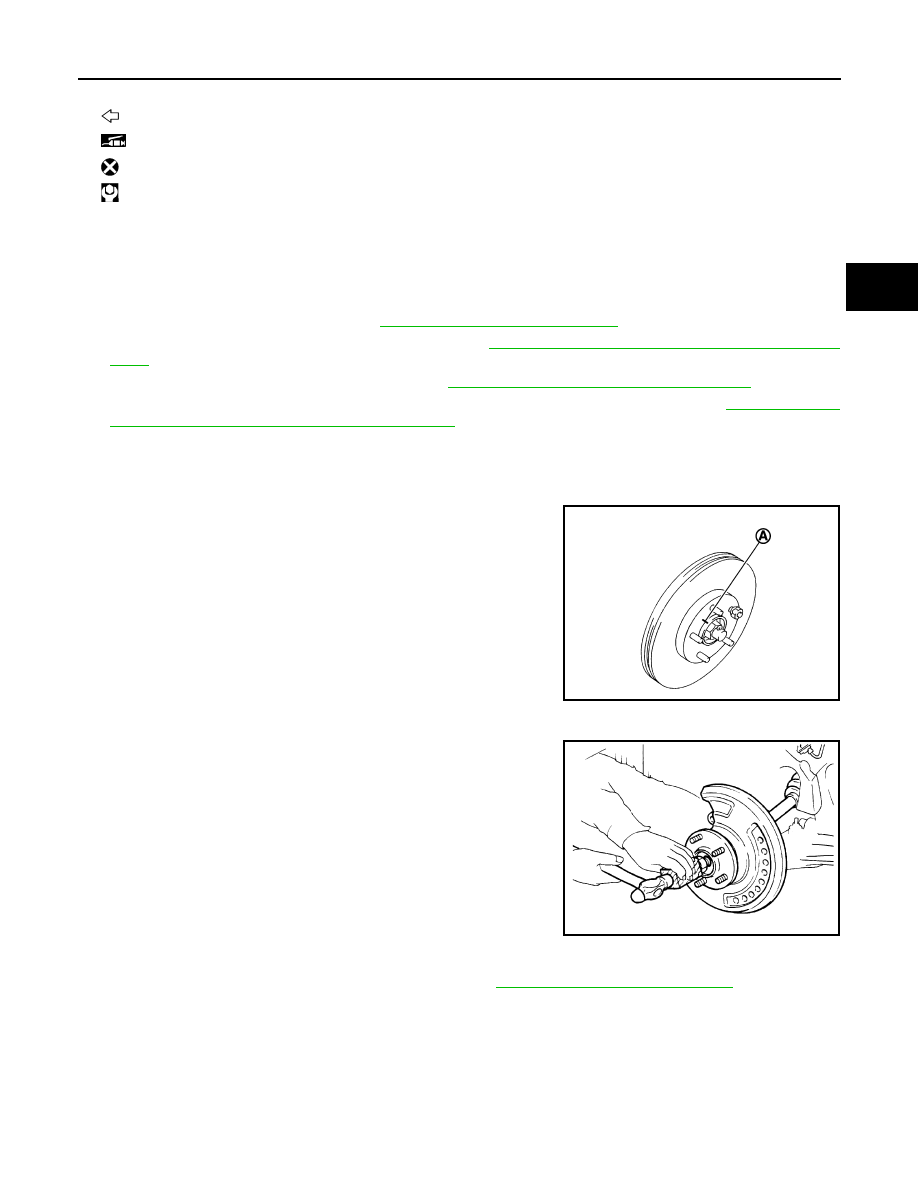

• Put matching marks (A) on the wheel hub assembly and

the disc rotor before removing the disc rotor.

• Never drop disc rotor.

6. Remove cotter pin, and adjusting cap, and then loosen wheel hub lock nut with power tool.

7. Patch wheel hub lock nut with a piece of wood. Hammer the

wood to disengage wheel hub assembly from drive shaft.

NOTE:

Use suitable puller, if wheel hub assembly and drive shaft can-

not be separated even after performing the above procedure.

8. Remove wheel hub lock nut.

9. Remove strut assembly from steering knuckle. Refer to

FSU-9, "Removal and Installation"

.

10. Remove drive shaft from wheel hub assembly.

CAUTION:

• Never place drive shaft joint at an extreme angle. Also be careful not to overextend slide joint.

• Never allow drive shaft to hang down without support for joint sub-assembly, shaft and the other

parts.

13. Heat insulator

: Wheel side

: Fill NISSAN Genuine grease or equivalent.

: Always replace after every disassembly.

: N·m (kg-m, ft-lb)

JPDIG0066ZZ

JPDIG0070ZZ