Nissan Juke F15. Manual - part 784

FRONT DRIVE SHAFT BOOT

FAX-75

< REMOVAL AND INSTALLATION >

[TYPE 2]

C

E

F

G

H

I

J

K

L

M

A

B

FAX

N

O

P

CAUTION:

• Since the drive shaft is assembled by press-fitting, use the tightening torque range for the wheel

hub lock nut.

• Be sure to use torque wrench to tighten the wheel hub lock nut. Never use a power tool.

• Never reuse wheel hub lock nut.

NOTE:

Wheel hub lock nut tightening torque does not over torque for avoiding axle noise, and does not less than

torque for avoiding looseness.

22. When installing a cotter pin (1) and adjusting cap (2), securely

bend the basal portion to prevent rattles.

CAUTION:

Never reuse cotter pin.

23. Install tires. Refer to

.

24. Perform inspection after installation. Refer to

.

Transaxle Side

• Install drive shaft to vehicle.

- Installation: Refer to

FAX-83, "2WD : Removal and Installation"

- Assembly: Refer to

FAX-87, "2WD : Disassembly and Assembly"

.

2WD : Inspection

INFOID:0000000012201556

INSPECTION AFTER INSTALLATION

1. Check wheel sensor harness for proper connection. Refer to

BRC-147, "FRONT WHEEL SENSOR :

.

2. Check the wheel alignment. Refer to

.

3. Adjust neutral position of steering angle sensor. Refer to

.

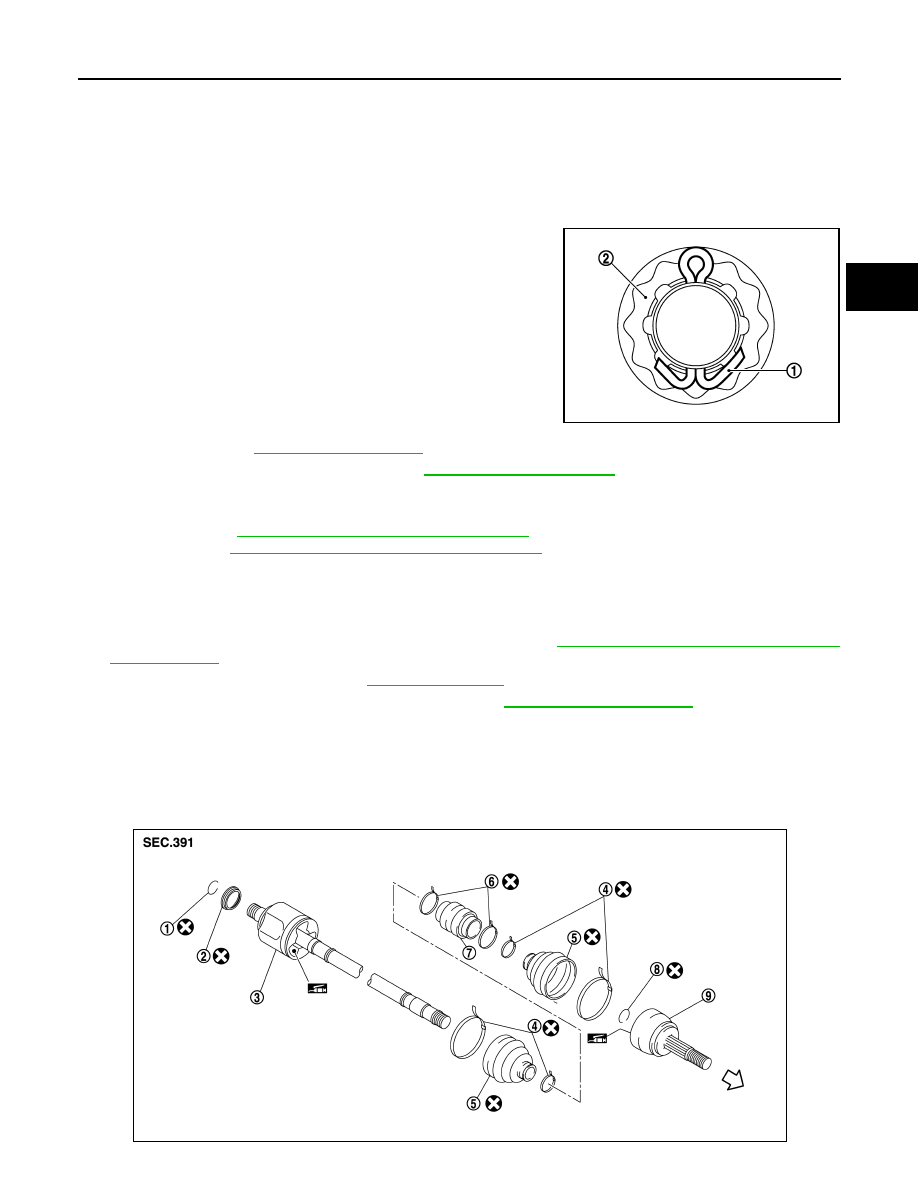

AWD

AWD : Exploded View

INFOID:0000000012201557

LEFT SIDE

JPDIF0295ZZ

JSDIA2093ZZ