Nissan Juke F15. Manual - part 686

EM-298

< UNIT DISASSEMBLY AND ASSEMBLY >

[MR EXCEPT FOR NISMO RS MODELS]

CYLINDER BLOCK

NOTE:

Piston and piston pin are service parts for assembly.

- When replacing the connecting rod, refer to

EM-304, "Selective-fit Service Parts"

rod bearing.

Cylinder Block Upper Surface Distortion

• Remove old gasket on cylinder block upper surface using a scraper. Also remove oil, scale, and carbon

deposits.

CAUTION:

Never allow gasket fragments to enter oil or engine coolant passages.

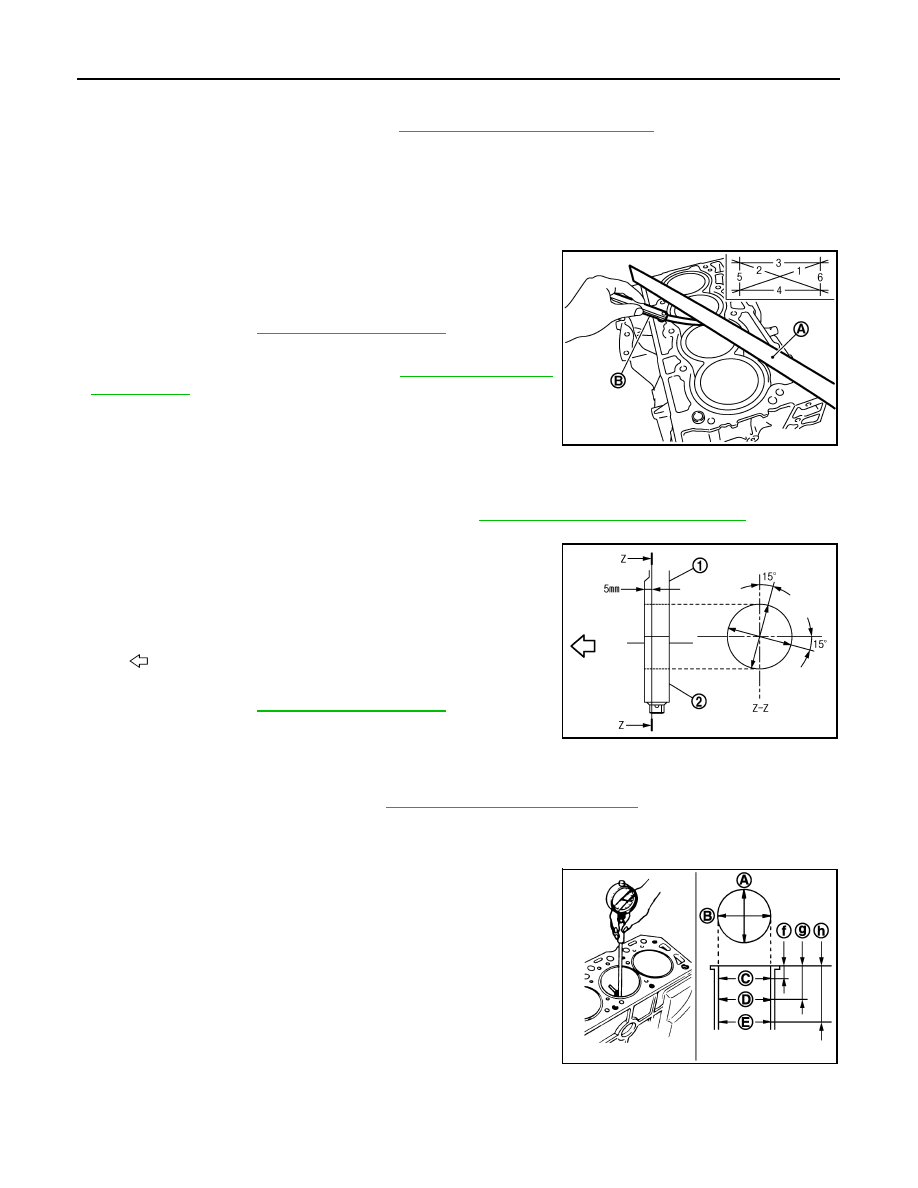

• Check flatness of cylinder block upper surface using a straight-

edge (A) and a feeler gauge (B). Measure distortion, at several

points each in six directions.

• If the limit is exceeded, replace the cylinder block.

- When replacing the cylinder block, refer to

Main Bearing Housing Inner Diameter

• Without installing main bearing, install main bearing cap, and tighten main bearing cap bolts to the specified

torque.

- For main bearing cap bolt tightening procedure, refer to

EM-287, "Disassembly and Assembly"

.

• Measure the main bearing housing inside diameter with a bore gauge.

• Measure the position shown in the figure (5 mm rearward from

main bearing housing front side end surface) in two directions, as

shown in the figure. Use the smaller one as the measured value.

• If the result is outside the standard, replace the cylinder block.

NOTE:

Main bearing cap is machined together with cylinder block, so they cannot be replaced separately.

- When replacing the cylinder block, refer to

EM-304, "Selective-fit Service Parts"

and select the main bearing.

Piston-to-cylinder Bore Clearance

Cylinder bore inner diameter

• Use a bore gauge and measure at three points from the top of the

engine (upper, middle, lower: “C”, “D”, and “E” as shown in the fig-

ure) in two directions (“A”, “B”) for measurement at a total of six

points.

NOTE:

The measurement point for bore grade is 60 mm below the cylin-

der head mounting surface (position “D” in the figure). Measure the

dimension in the engine LH/RH directions (“B” in the figure).

Limit : Refer to

PBIC3250J

1

: Cylinder block

2

: Main bearing cap

: Engine front

Stan

dard

: Refer to

PBIC3271J

f

: 10 mm (0.39 in)

g

: 60 mm (2.36 in)

h

: 130 mm (5.12 in)

JPBIA2059ZZ