Nissan Juke F15. Manual - part 685

EM-294

< UNIT DISASSEMBLY AND ASSEMBLY >

[MR EXCEPT FOR NISMO RS MODELS]

CYLINDER BLOCK

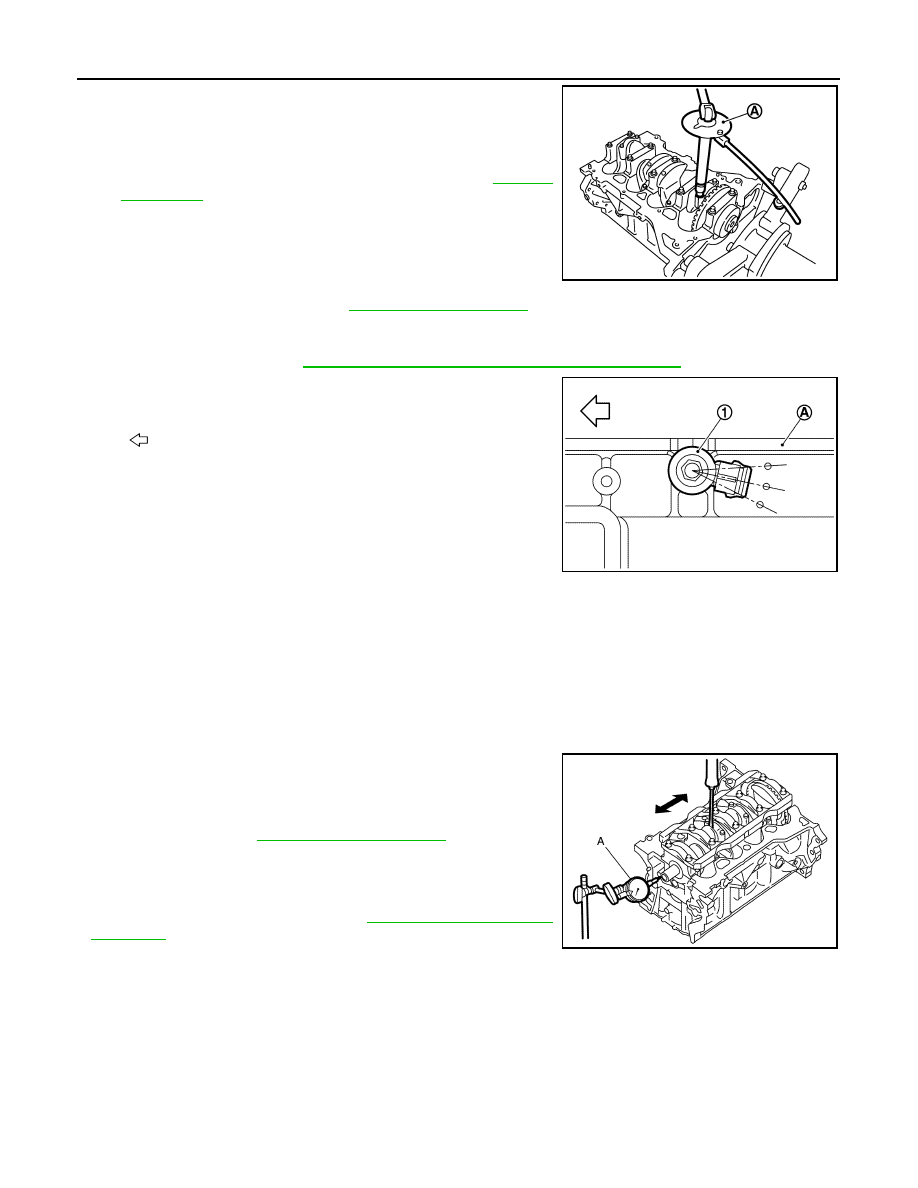

Check tightening angle with an angle wrench [SST:

KV10112100 (BT8653-A)] A or a protractor. Never estimate

tightening angle visually.

• Check that the crankshaft rotates smoothly by hand after tight-

ening the main bearing cap bolt.

• Check the connecting rod side clearance. Refer to

.

14. Install the oil pan (upper). Refer to

NOTE:

Install the rear oil seal after installing the oil pan (upper).

15. Install rear oil seal. Refer to

EM-271, "REAR OIL SEAL : Removal and Installation"

16. Install knock sensor (1) in the direction shown in the figure.

CAUTION:

• Never subject parts to impact. If any impact is applied,

replace it.

• Check that no foreign material adheres to cylinder block

and knock sensor mounting surfaces.

• Install connectors so that they are positioned toward

engine rear.

• Be sure to use specified bolts.

• Never hold connector while tightening bolts.

• Never allow installed sensor connector to interfere with other parts.

17. Assemble in the reverse order of disassembly.

Inspection

INFOID:0000000012197446

INSPECTION AFTER DISASSEMBLY

Crankshaft Side Clearance

• Move crankshaft to front or rear, and measure thrust bearing-to-

crank arm clearance using a dial indicator (A).

• If the limit is exceeded, replace the thrust bearing and then mea-

sure again. Replace the crankshaft if it still exceeds the limit.

- When replacing the crankshaft, refer to

and select the main bearing and connecting rod bear-

ing.

Connecting Rod Side Clearance

PBIC3245J

A

: Left side of cylinder block

: Engine front

JPBIA5163ZZ

Stan

dard

: Refer to

Limit

JPBIA4436ZZ