Nissan Juke F15. Manual - part 616

EM-18

< SYMPTOM DIAGNOSIS >

[MR FOR NISMO RS MODELS]

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

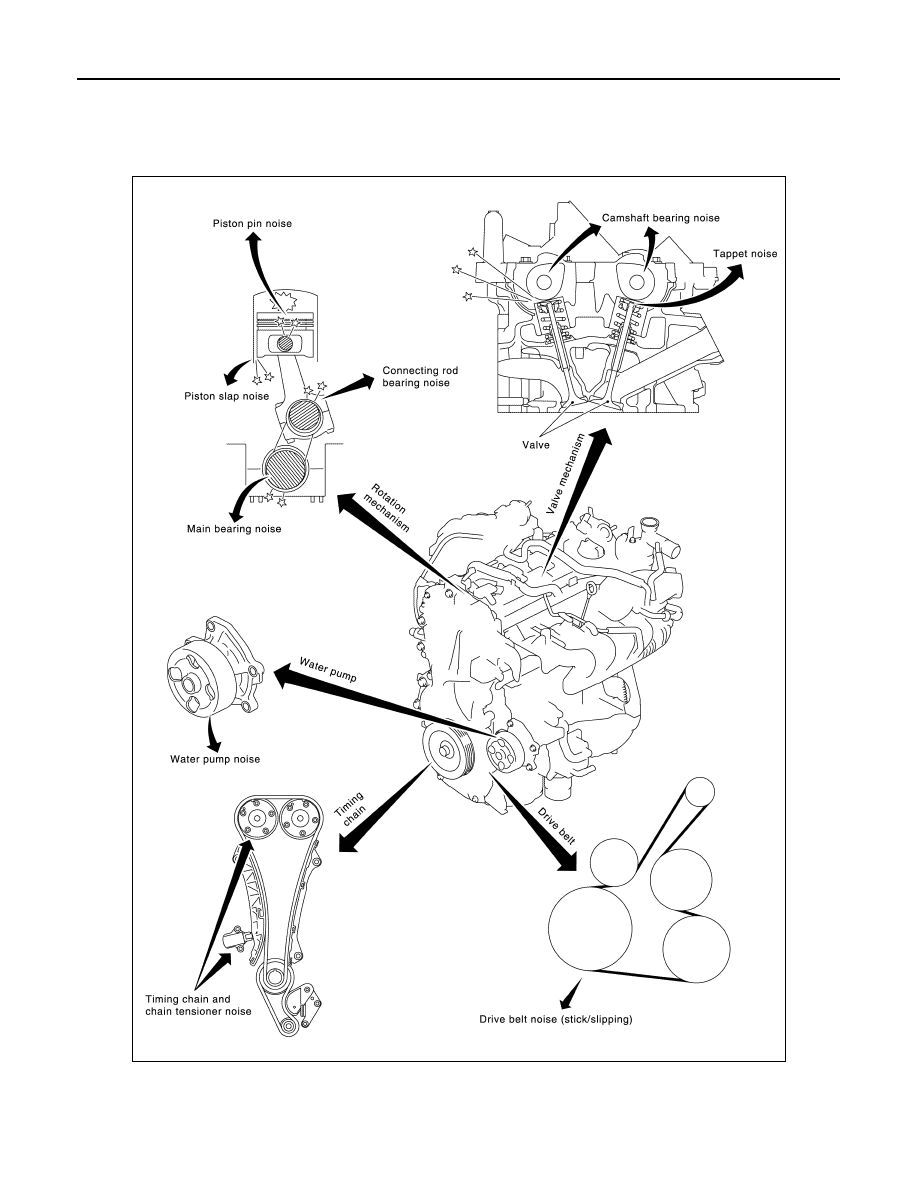

NVH troubleshooting Chart

INFOID:0000000012197239

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

JPBIA4301GB