Nissan Juke F15. Manual - part 284

FRONT OIL SEAL

DLN-141

< REMOVAL AND INSTALLATION >

[REAR FINAL DRIVE: RTVS]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

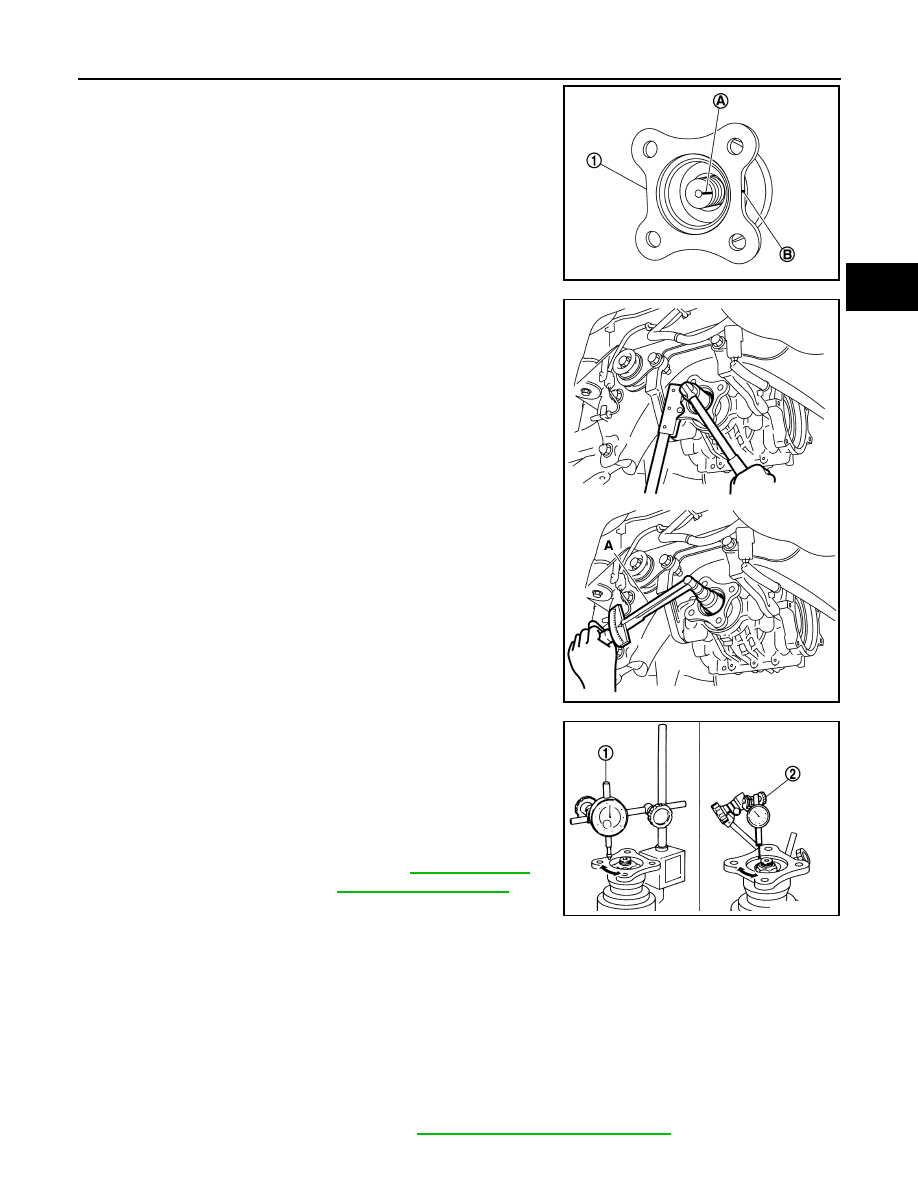

3. Align the matching mark (A) of drive pinion with the matching

mark (B) of companion flange (1), and then install the compan-

ion flange.

4. Temporarily tighten drive pinion lock nut to drive pinion, using

the flange wrench (Commercial service tool).

CAUTION:

• Never reuse drive pinion lock nut.

• Apply anti-corrosion oil to the thread and seat of new

drive pinion lock nut.

5. Tighten drive pinion lock nut within the limits of specified torque

so as to keep the pinion bearing preload within a standard val-

ues, using the preload gauge (A) [SST: ST3127S000 (J-25765-

A)].

CAUTION:

• Adjust to the lower limit of the drive pinion lock nut tight-

ening torque first.

• If the preload torque exceeds the specified value, replace

collapsible spacer and tighten it again to adjust. Never

loosen drive pinion lock nut to adjust the preload torque.

6. Check for companion flange runout as follows:

• For companion flange face, fit a dial indicator (1) onto the com-

panion flange face (inner side of the propeller shaft mounting

bolt holes). For inner side of the companion flange, fit a test

indicator (2) to the inner side of companion flange (socket

diameter).

• Rotate companion flange to check for runout.

• If the runout value is outside the runout limit, follow the proce-

dure below to adjust.

- Check for runout while changing the phase between companion flange and drive pinion by 90

° step, and

search for the position where the runout is the minimum.

- If the runout value is still outside of the limit after the phase has been changed, replace companion

flange.

- If the runout value is still outside of the limit after companion flange has been replaced, possible cause

will be an assembly malfunction of drive pinion.

7. Make a stamping for identification of front oil seal replacement frequency. Refer to “Identification stamp of

replacement frequency of front oil seal”.

CAUTION:

Make a stamping after replacing front oil seal.

8. Install electric controlled couplings. Refer to

DLN-145, "Removal and Installation"

.

JSDIA2118ZZ

Total preload torque

: A value that add 0.1 – 0.4

N·m (0.01 – 0.04 kg-m, 1.0 –

3.0 in-lb) to the measured

value before removing.

JSDIA2123ZZ

Companion flange runout : Refer to

.

JSDIA2539ZZ