Content .. 1230 1231 1232 1233 ..

Nissan Juke F15. Manual - part 1232

TM-118

< UNIT DISASSEMBLY AND ASSEMBLY >

[6MT: RS6F52H]

INPUT SHAFT AND GEARS

Disassembly and Assembly

INFOID:0000000012200825

DISASSEMBLY

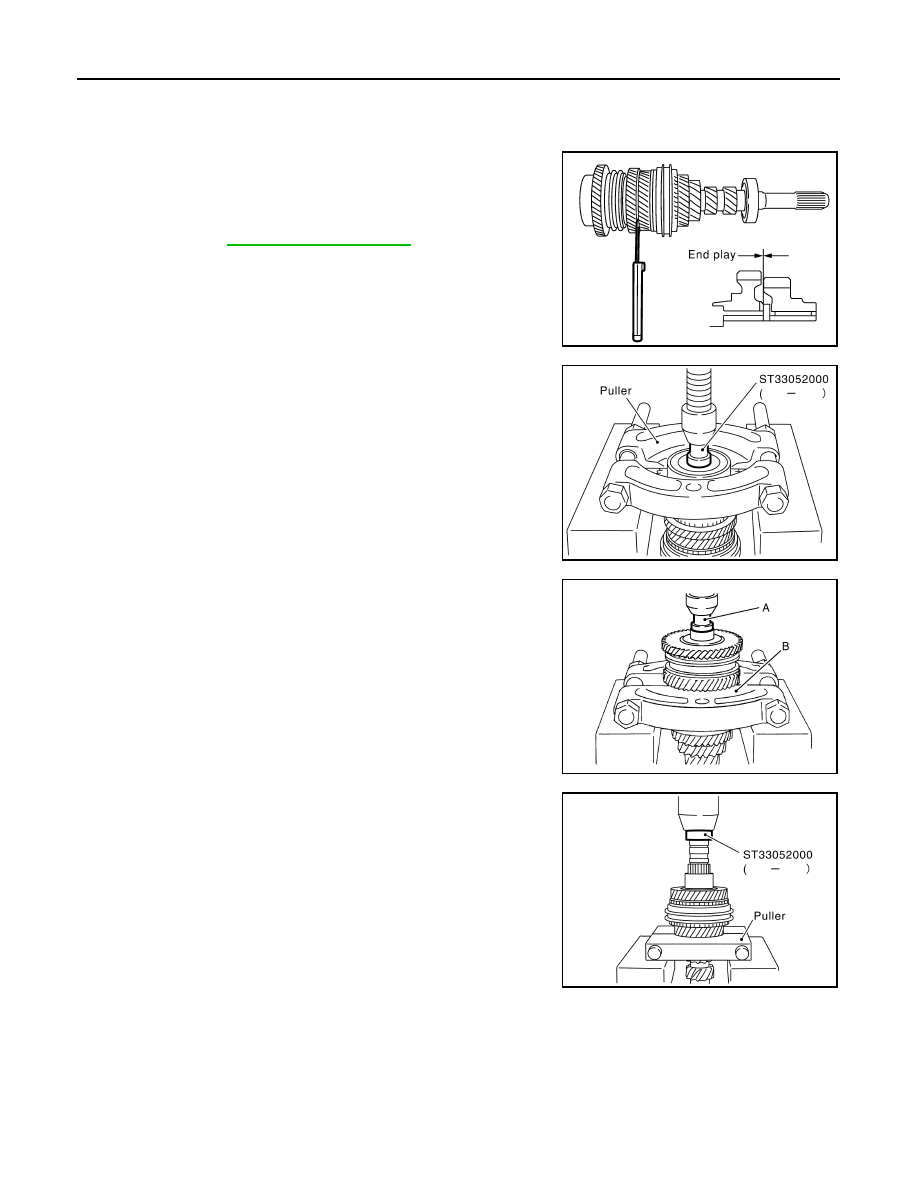

1. Before disassembling, measure end play for 3rd, 4th, 5th, and

6th input gears.

2. Remove oil channel.

3. Press out input shaft rear bearing using Tool and a puller.

4. Remove snap ring.

5. Press out 6th input gear, 6th needle bearing, 6th input gear

bushing, 5th-6th synchronizer hub assembly, and 5th input gear

using Tool (A) and a puller (B).

6. Remove 5th needle bearing.

7. Press out 5th input gear bushing, thrust washer, 4th input gear,

4th needle bearing, 4th input gear bushing, 3rd-4th synchronizer

hub assembly, and 3rd input gear using Tool and a puller.

8. Remove 3rd needle bearing.

End play standard value

: Refer to

SCIA0966E

Tool number

: ST33052000 ( — )

SCIA1037E

Tool number

A: ST33052000 ( — )

PCIB1882E

Tool number

: ST33052000 ( — )

SCIA1030E