Content .. 1229 1230 1231 1232 ..

Nissan Juke F15. Manual - part 1231

TM-114

< UNIT DISASSEMBLY AND ASSEMBLY >

[6MT: RS6F52H]

TRANSAXLE ASSEMBLY

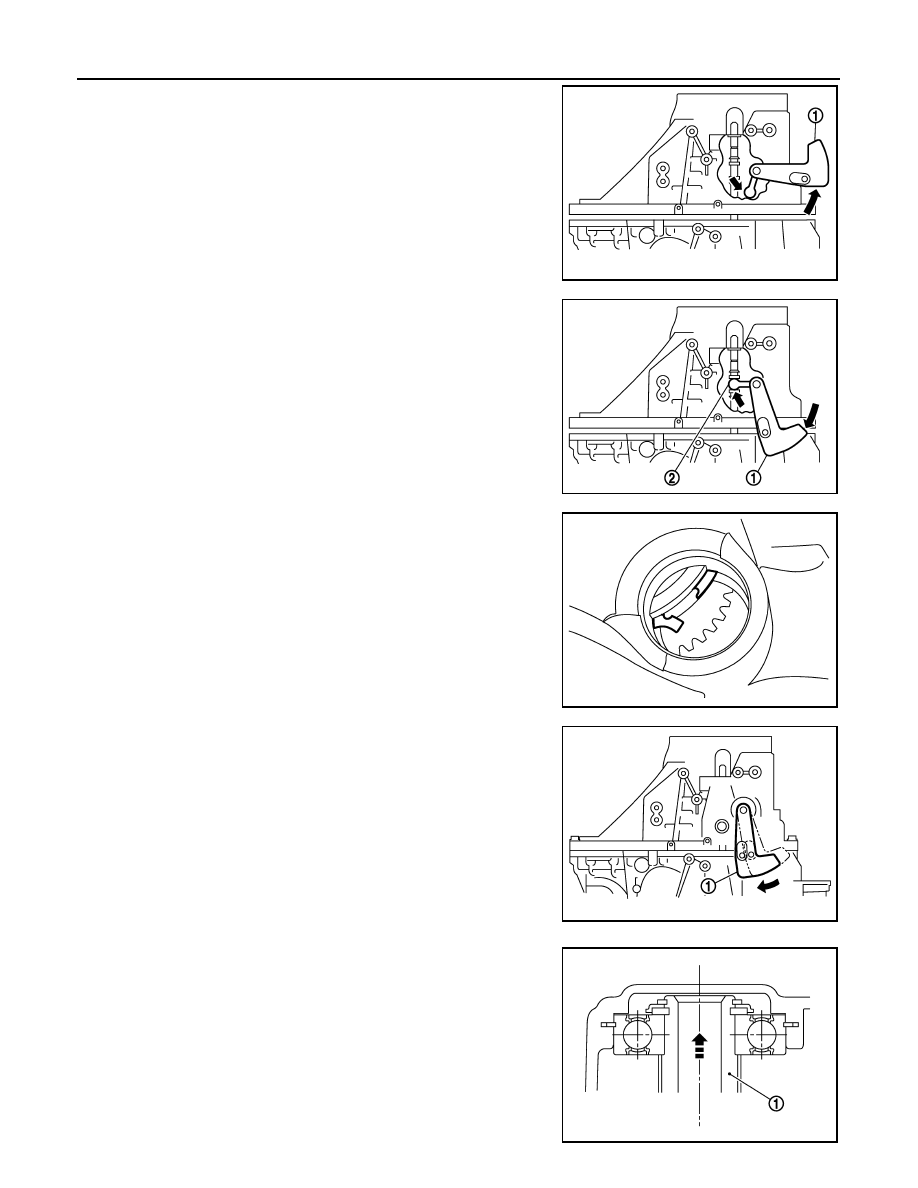

c.

With shifter lever A (1) held in the position shown, temporarily

assemble transaxle case to clutch housing.

CAUTION:

Do not damage striking rod oil seal.

NOTE:

Make sure to hold shifter lever A in the position shown. Other-

wise transaxle case cannot be installed to clutch housing.

d. While rotating shifter lever A (1) in the direction of the arrow

shown, assemble transaxle case to clutch housing.

e. Accessing from the bore plug hole, expand snap ring at main-

shaft rear bearing so that the ring catches the periphery of main-

shaft rear bearing.

f.

Temporarily tighten transaxle case bolts.

2. Shift the shifter lever A to 2nd gear position.

NOTE:

• The 2nd gear position is attained when shifter lever A (1) is in

the position shown.

• When transaxle is shifted to the 2nd gear position, mainshaft

assembly (1) is lifted.

PCIB1808E

2

: shifter lever B

PCIB1929E

PCIB1840E

PCIB1809E

PCIB1923E