Content .. 1227 1228 1229 1230 ..

Nissan Juke F15. Manual - part 1229

TM-106

< UNIT DISASSEMBLY AND ASSEMBLY >

[6MT: RS6F52H]

TRANSAXLE ASSEMBLY

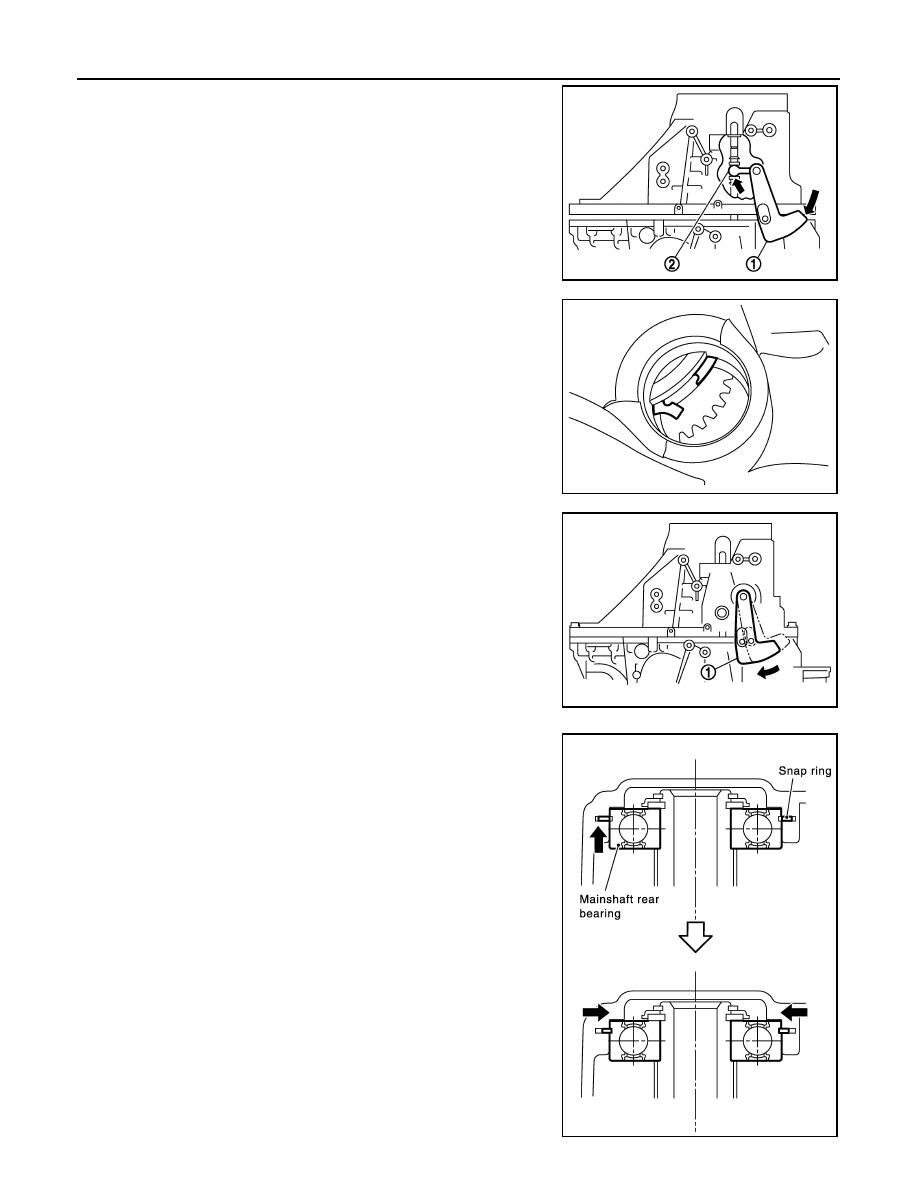

f.

While rotating shifter lever A (1) in the direction of the arrow

shown, assemble transaxle case to clutch housing.

g. Accessing from the bore plug hole, expand snap ring at main-

shaft rear bearing so that the ring catches the periphery of main-

shaft rear bearing.

h. Temporarily tighten transaxle case bolts.

i.

Shift the shifter lever A (1) to 2nd gear position.

NOTE:

• The 2nd gear position is attained when shifter lever A is in the

position shown.

• When transaxle is shifted to the 2nd gear position, mainshaft

assembly is lifted.

j.

Seat snap ring in the groove on mainshaft rear bearing. If snap

ring is not seated in the groove on mainshaft rear bearing,

remove transaxle case and repeat the procedure from step d.

2

: shifter lever B

PCIB1929E

PCIB1840E

PCIB1809E

SCIA0893E