Content .. 1206 1207 1208 1209 ..

Nissan Juke F15. Manual - part 1208

TM-22

< PERIODIC MAINTENANCE >

[6MT: RS6F94R]

GEAR OIL

PERIODIC MAINTENANCE

GEAR OIL

Inspection

INFOID:0000000012200760

OIL LEAKAGE

Make sure that gear oil is not leaking from transaxle or around it.

OIL LEVEL

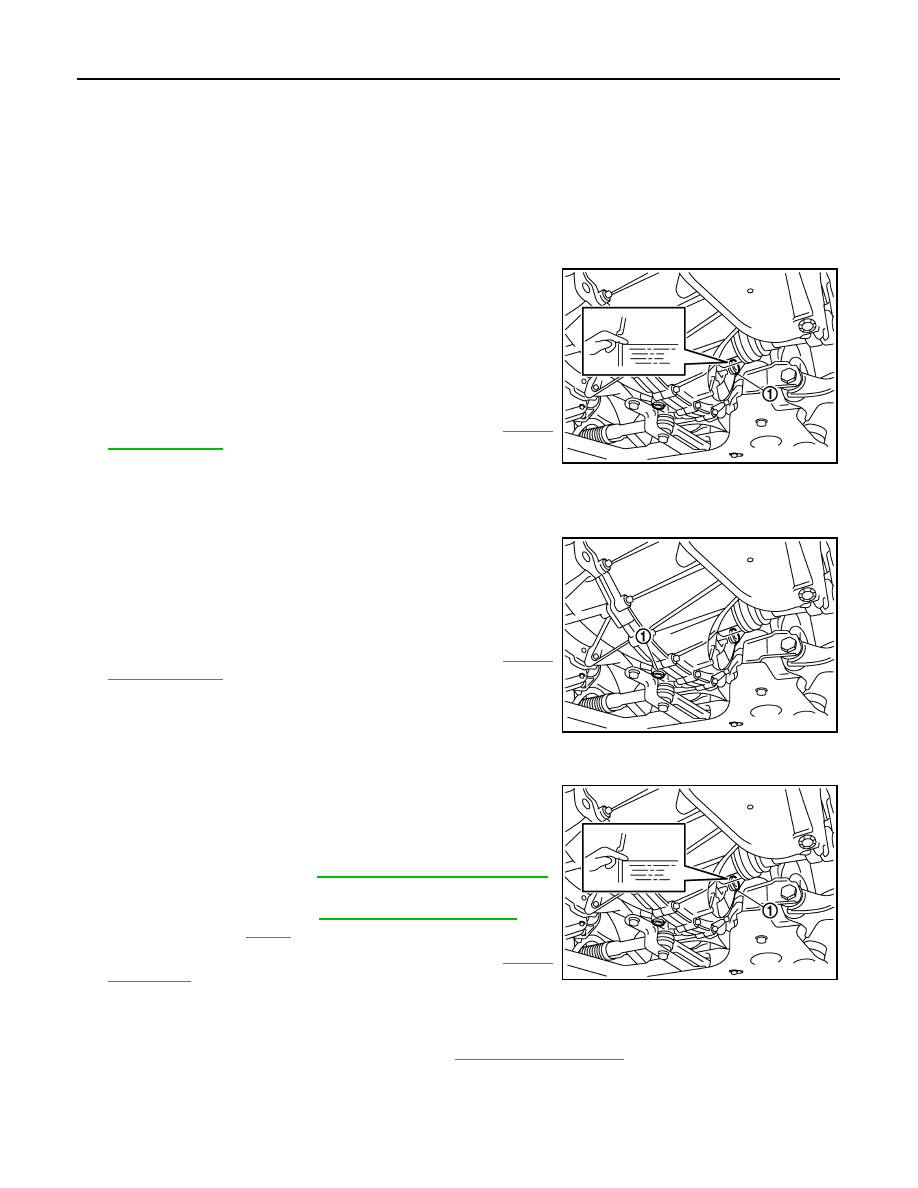

1. Remove filler plug (1) and gasket from transaxle case.

2. Check the oil level from filler plug mounting hole as shown in the

figure.

CAUTION:

Never start engine while checking oil level.

3. Set a gasket on filler plug and then install it to transaxle case.

CAUTION:

Never reuse gasket.

4. Tighten filler plug to the specified torque. Refer to

Draining

INFOID:0000000012200761

1. Start engine and let it run to warm up transaxle.

2. Stop engine. Remove drain plug (1) and gasket, using a socket

[Commercial service tool] and then drain gear oil.

3. Set a gasket on drain plug and install it to clutch housing, using

a socket [Commercial service tool].

CAUTION:

Never reuse gasket.

4. Tighten drain plug to the specified torque. Refer to

Refilling

INFOID:0000000012200762

1. Remove filler plug (1) and gasket from transaxle case.

2. Fill with new gear oil until oil level reaches the specified limit at

filler plug mounting hole as shown in the figure.

3. After refilling gear oil, check the oil level. Refer to

4. Set a gasket on filler plug and then install it to transaxle case.

CAUTION:

Never reuse gasket.

5. Tighten filler plug to the specified torque. Refer to

SCIA7623E

SCIA7622E

Oil grade and

viscosity

: Refer to

MA-11, "Fluids and Lubricants"

Oil capacity

: Refer to

SCIA7623E