содержание .. 683 684 685 686 ..

Nissan Tiida C11. Manual - part 685

EM-92

< REMOVAL AND INSTALLATION >

[HR16DE]

ENGINE ASSEMBLY

4.

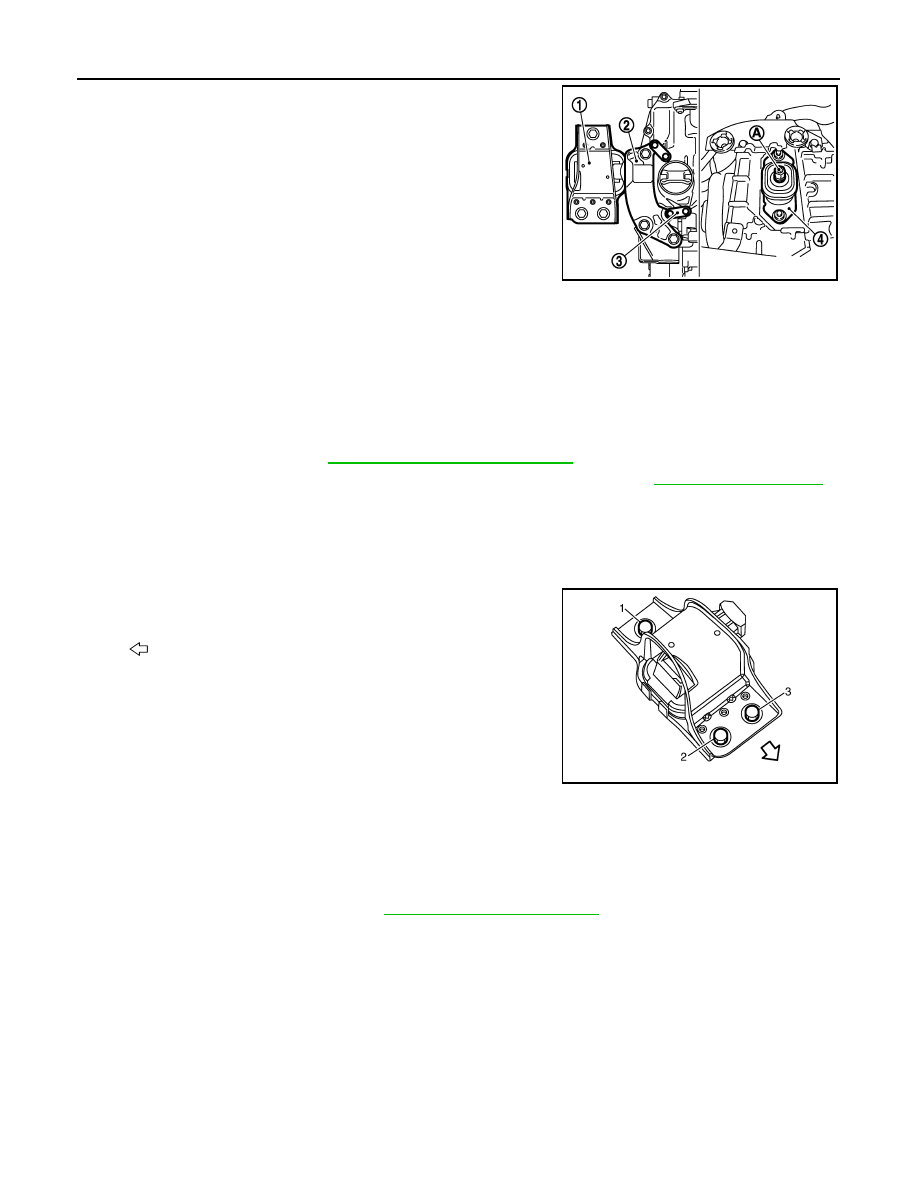

Remove engine mounting insulator (RH) (1), engine mounting

bracket (RH) (2) and engine mounting stay (3).

5.

Remove engine mounting through bolt-securing nut (A).

6.

Carefully lower jack, or raise lift to remove the engine and the transaxle assembly.

CAUTION:

• Make sure that no part interferes with the vehicle side.

• Before and during this lifting, always check if any harnesses are left connected.

• During the removal, always be careful to prevent the vehicle from falling off the lift due to

changes in the center of gravity.

• If necessary, support the vehicle by setting jack or suitable tool at the rear.

Separation

1.

Remove starter motor. Refer to

STR-13, "Removal and Installation"

.

2.

Lift with a hoist and separate the engine from the transaxle assembly. Refer to

.

INSTALLATION

Installation is in the reverse order of removal.

• Do not allow engine oil to get on engine mounting insulator. Be careful not to damage engine mounting insu-

lator.

• Make sure that each mounting insulator is seated properly, and tighten mounting nuts and bolts.

• Tighten engine mounting insulator (RH) bolts in the numerical

order shown.

Inspection

INFOID:0000000001381426

INSPECTION AFTER INSTALLATION

Inspection for Leaks

• Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to

MA-19, "Fluids and Lubricants"

.

• Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gases, or any oil/fluids includ-

ing engine oil and engine coolant.

• Bleed air from lines and hoses of applicable lines, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

4

: Engine mounting insulator (LH)

JPBIA0512ZZ

: Vehicle front

JPBIA0280ZZ