содержание .. 682 683 684 685 ..

Nissan Tiida C11. Manual - part 684

EM-88

< ON-VEHICLE REPAIR >

[HR16DE]

CYLINDER HEAD

6.

Install valve spring.

NOTE:

It can be installed in either direction.

7.

Install valve spring retainer.

8.

Install valve collet.

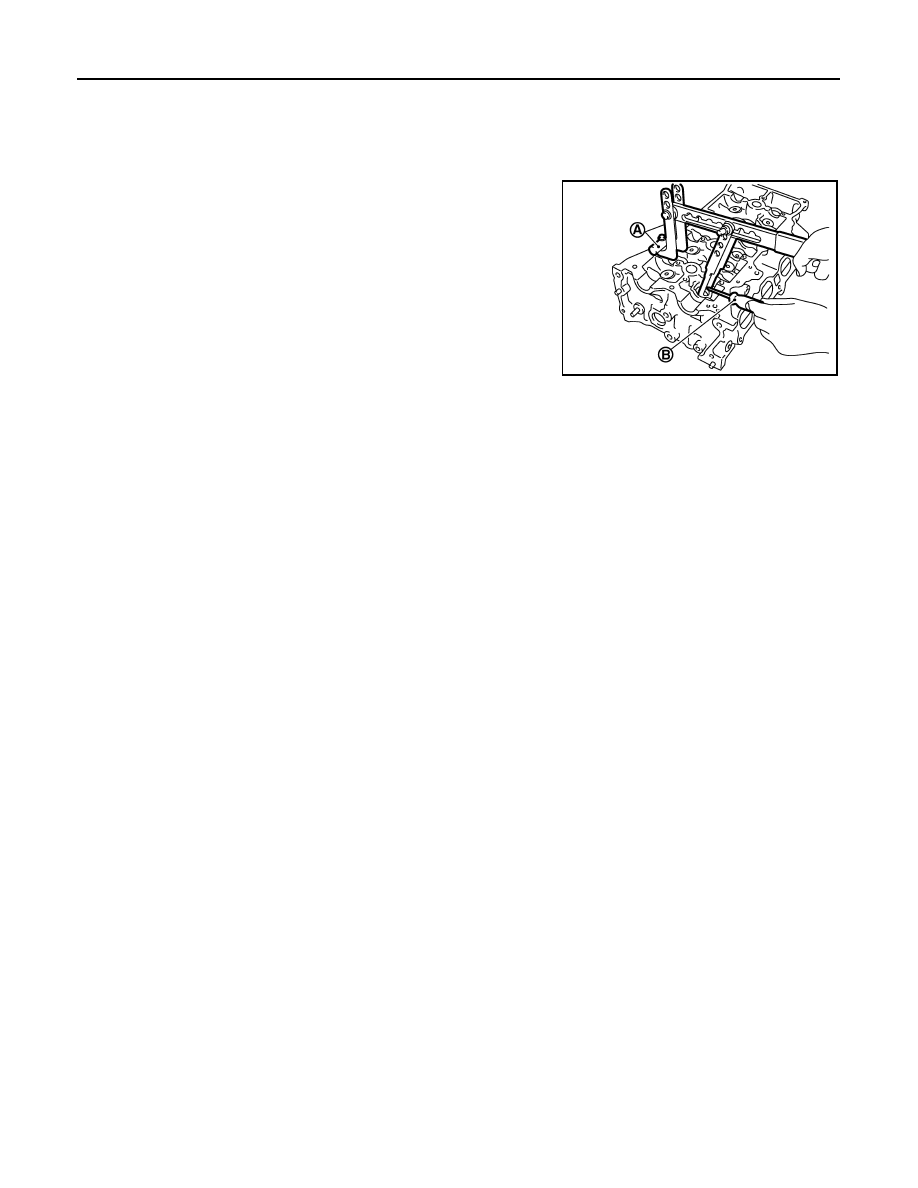

• Compress valve spring with the valve spring compressor, the

attachment and the adapter [SST: KV10116200] (A). Install

valve collet with a magnet hand (B).

CAUTION:

Be careful not to damage valve lifter holes.

• Tap valve stem edge lightly with a plastic hammer after instal-

lation to check its installed condition.

9.

Install valve lifter.

10. Install spark plug with a suitable tool.

PBIC3727E