содержание .. 680 681 682 683 ..

Nissan Tiida C11. Manual - part 682

EM-80

< ON-VEHICLE REPAIR >

[HR16DE]

CYLINDER HEAD

CYLINDER HEAD

Removal and Installation

INFOID:0000000001381421

REMOVAL

1.

Release fuel pressure. Refer to

(EURO-OBD),

(WITHOUT

EURO-OBD).

2.

Drain engine coolant and engine oil. Refer to

CO-11, "Changing Engine Coolant"

.

CAUTION:

• Perform this step when the engine is cold.

• Never spill engine coolant and engine oil on drive belt.

3.

Remove the following components and related parts.

• Front fender protector (RH): Refer to

EXT-22, "Removal and Installation"

• Generator: Refer to

CHG-15, "Removal and Installation"

• Exhaust front tube: Refer to

.

• Exhaust manifold: Refer to

• Intake manifold: Refer to

• Fuel tube and fuel injector: Refer to

.

• Water outlet: Refer to

CO-24, "Removal and Installation"

• Drive belt: Refer to

EM-16, "Removal and Installation"

• Front cover: Refer to

• Camshaft: Refer to

.

4.

Remove cylinder head loosening bolts in reverse order as

shown with cylinder head wrench (commercial service tool).

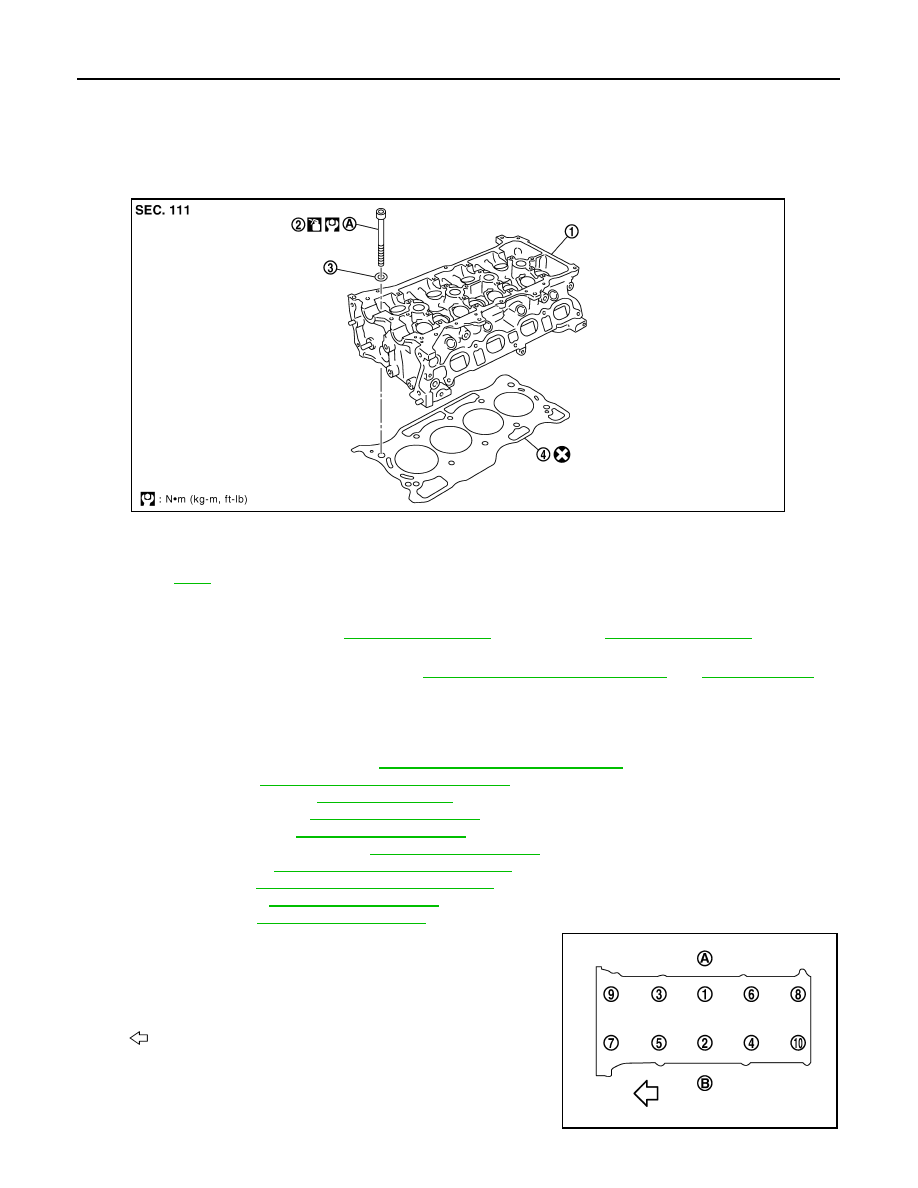

1.

Cylinder head assembly

2.

Cylinder head bolt

3.

Washer

4.

Cylinder head gasket

A.

Refer to

PBIC3731E

A

: EXH side

B

: INT side

: Engine front

PBIC3732E