содержание .. 681 682 683 684 ..

Nissan Tiida C11. Manual - part 683

EM-84

< ON-VEHICLE REPAIR >

[HR16DE]

CYLINDER HEAD

6.

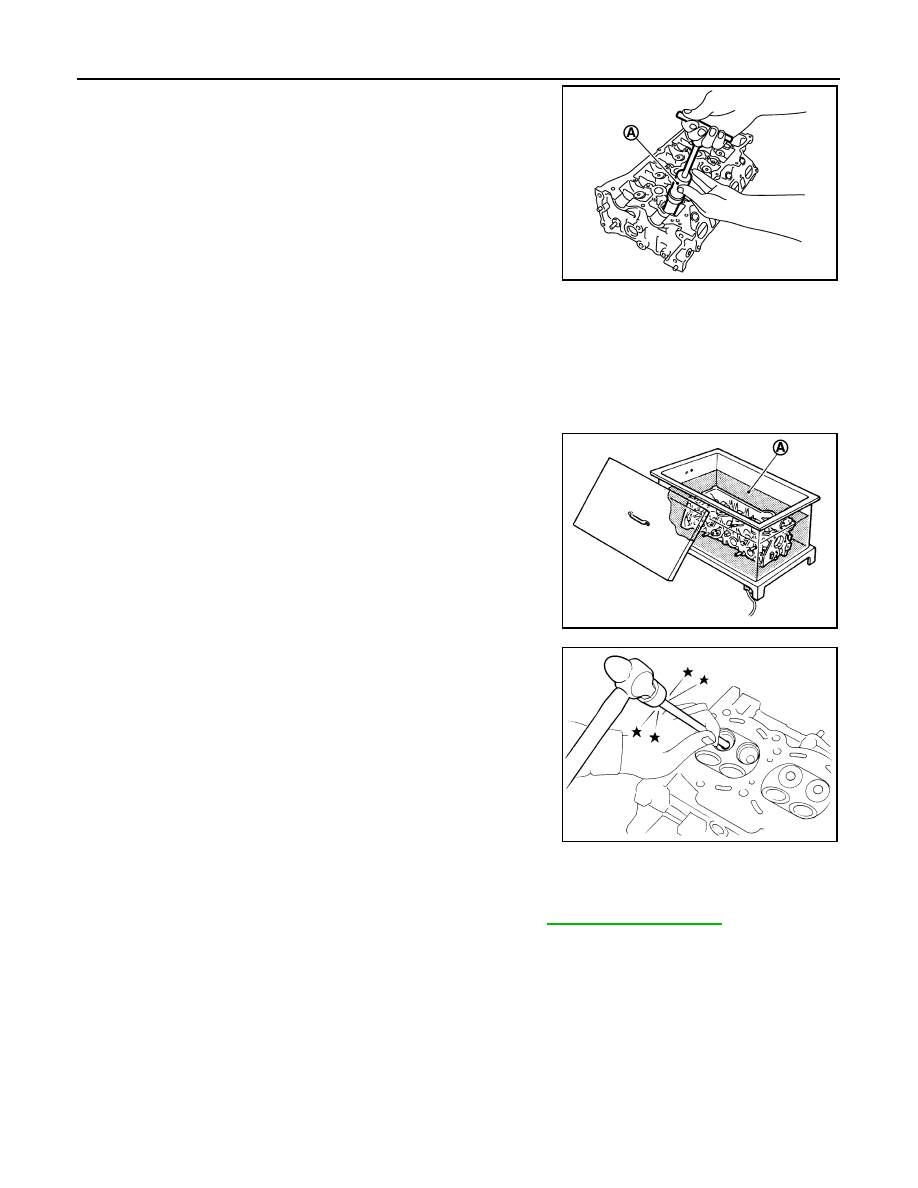

Remove valve oil seal with the valve oil seal puller [SST:

KV10107902] (A).

7.

Remove valve spring seat.

8.

Remove valve seat, if valve seat must be replaced.

• Bore out old seat until it collapses. Boring should not continue beyond the bottom face of the seat

recess in cylinder head. Set the machine depth stop to ensure this.

CAUTION:

Never bore excessively to prevent cylinder head from scratching.

9.

Remove valve guide, if valve guide must be replaced.

a.

To remove valve guide, heat cylinder head to 110 to 130

°

C (230

to 266

°

F) by soaking in heated oil (A).

b.

Drive out valve guide with a press [under a 20 kN (2 ton, 2.2 US

ton, 2.0 lmp ton) pressure] or a hammer and the valve guide drift

(commercial service tool).

WARNING:

Cylinder head contains heat. Wear protective equipment to

avoid getting burned.

INSPECTION AFTER DISASSEMBLY

Valve Dimensions

• Check the dimensions of each valve. For the dimensions, refer to

• If dimensions are out of the standard, replace valve and check valve seat contact. Check “VALVE SEAT

CONTACT”.

Valve Guide Clearance

Valve Stem Diameter

PBIC3728E

JPBIA0184ZZ

SEM931C