содержание .. 595 596 597 598 ..

Nissan Tiida C11. Manual - part 597

EC-1038

< SERVICE DATA AND SPECIFICATIONS (SDS)

[MR18DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

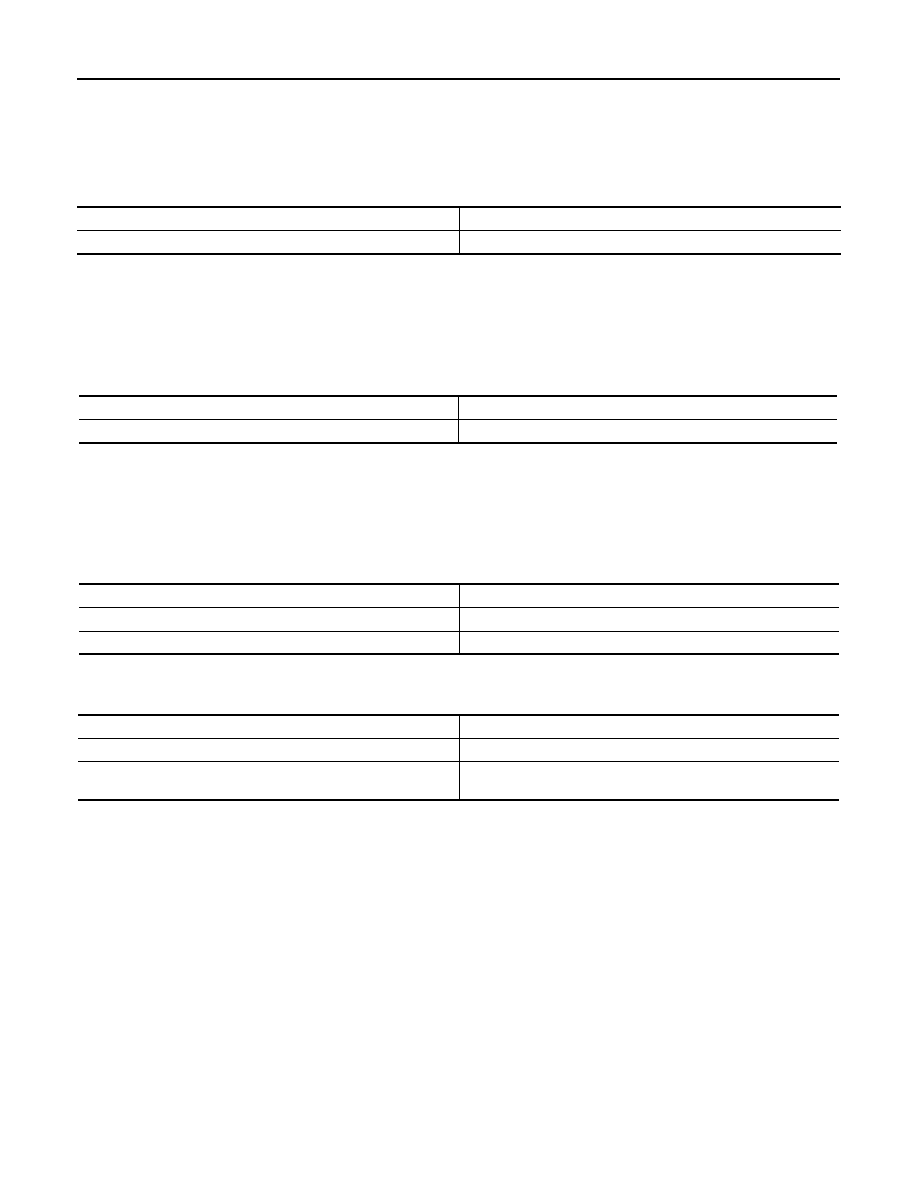

Idle Speed

INFOID:0000000001162007

*: Under the following conditions

• A/C switch: OFF

• Electric load: OFF (Lights, heater fan & rear window defogger)

• Steering wheel: Kept in straight-ahead position

Ignition Timing

INFOID:0000000001162008

*: Under the following conditions

• A/C switch: OFF

• Electric load: OFF (Lights, heater fan & rear window defogger)

• Steering wheel: Kept in straight-ahead position

Calculated Load Value

INFOID:0000000001162009

Mass Air Flow Sensor

INFOID:0000000001162010

*: Engine is warmed up to normal operating temperature and running under no load.

Condition

Specification

No load* (in Neutral position)

700

±

50 rpm

Condition

Specification

No load* (in Neutral position)

15

±

5

°

BTDC

Condition

Specification (Using CONSULT-III or GST)

At idle

10 – 35 %

At 2,500 rpm

10 – 35 %

Supply voltage

Battery voltage (11 – 14 V)

Output voltage at idle

0.8 – 1.1V*

Mass air flow (Using CONSULT-III or GST)

1.0 – 4.0 g·m/sec at idle*

2.0 – 10.0 g·m/sec at 2,500 rpm*