содержание .. 594 595 596 597 ..

Nissan Tiida C11. Manual - part 596

EC-1034

< PREPARATION >

[MR18DE]

PREPARATION

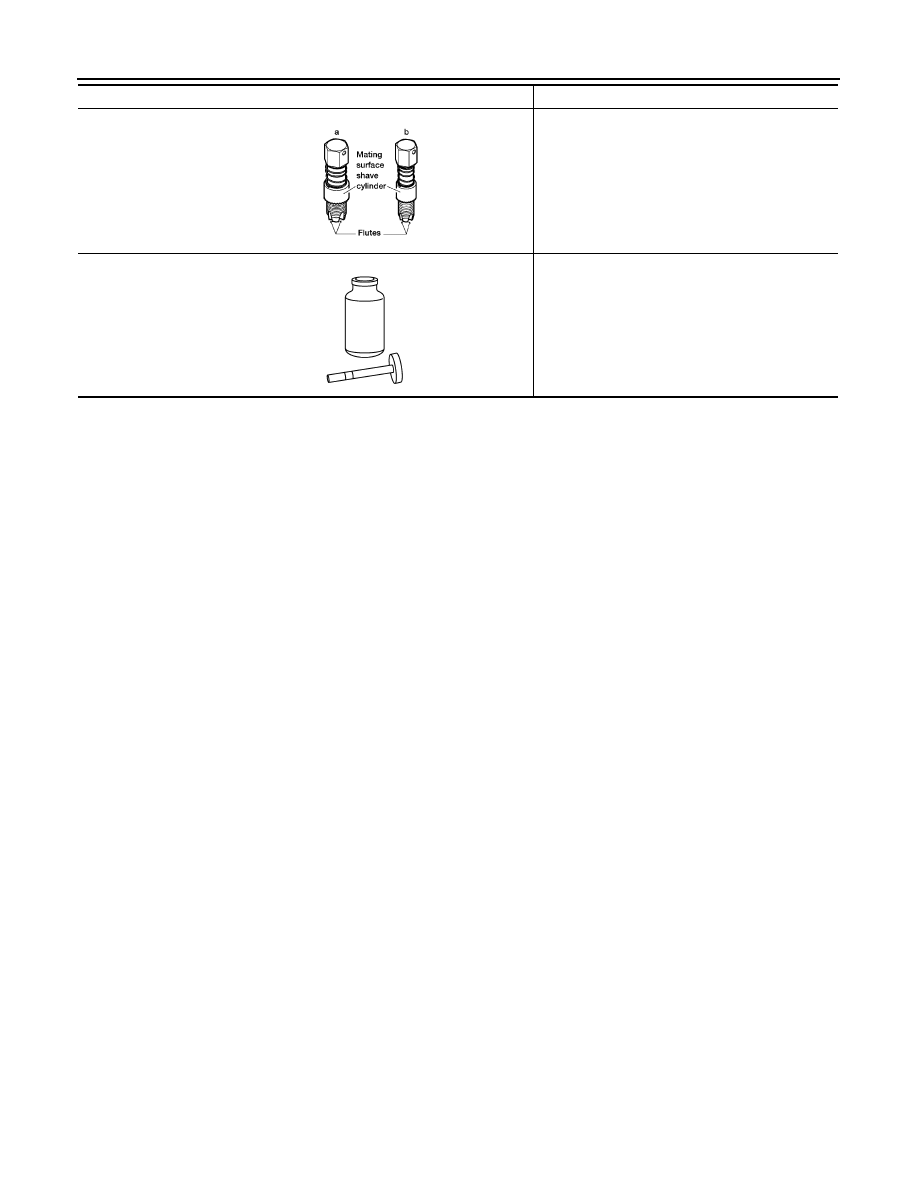

Oxygen sensor thread

cleaner

Reconditioning the exhaust system threads before

installing a new oxygen sensor. Use with anti-

seize lubricant shown below.

a: 18 mm diameter with pitch 1.5 mm for Zirco-

nia Oxygen Sensor

b: 12 mm diameter with pitch 1.25 mm for Tita-

nia Oxygen Sensor

Anti-seize lubricant

i.e.: (Permatex

TM

133AR or equivalent

meeting MIL specifica-

tion MIL-A-907)

Lubricating oxygen sensor thread cleaning tool

when reconditioning exhaust system threads.

Tool name

Description

AEM488

S-NT779