содержание .. 593 594 595 596 ..

Nissan Tiida C11. Manual - part 595

EC-1030

< PRECAUTION >

[MR18DE]

PRECAUTIONS

On Board Diagnostic (OBD) System of Engine

INFOID:0000000001679887

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MI) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

• Be sure to turn the ignition switch OFF and disconnect the negative battery cable before any repair

or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc. will

cause the MI to light up.

• Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MI to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

• Certain systems and components, especially those related to OBD, may use a new style slide-lock-

ing type harness connector. For description and how to disconnect, refer to

XX-XX, "*****"

.

• Be sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MI to light up due to the short circuit.

• Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MI to light up due to the malfunction of the EVAP system or fuel injection system, etc.

• Be sure to erase the unnecessary malfunction information (repairs completed) from the ECM before

returning the vehicle to the customer.

General Precautions

INFOID:0000000001162002

• Always use a 12 volt battery as power source.

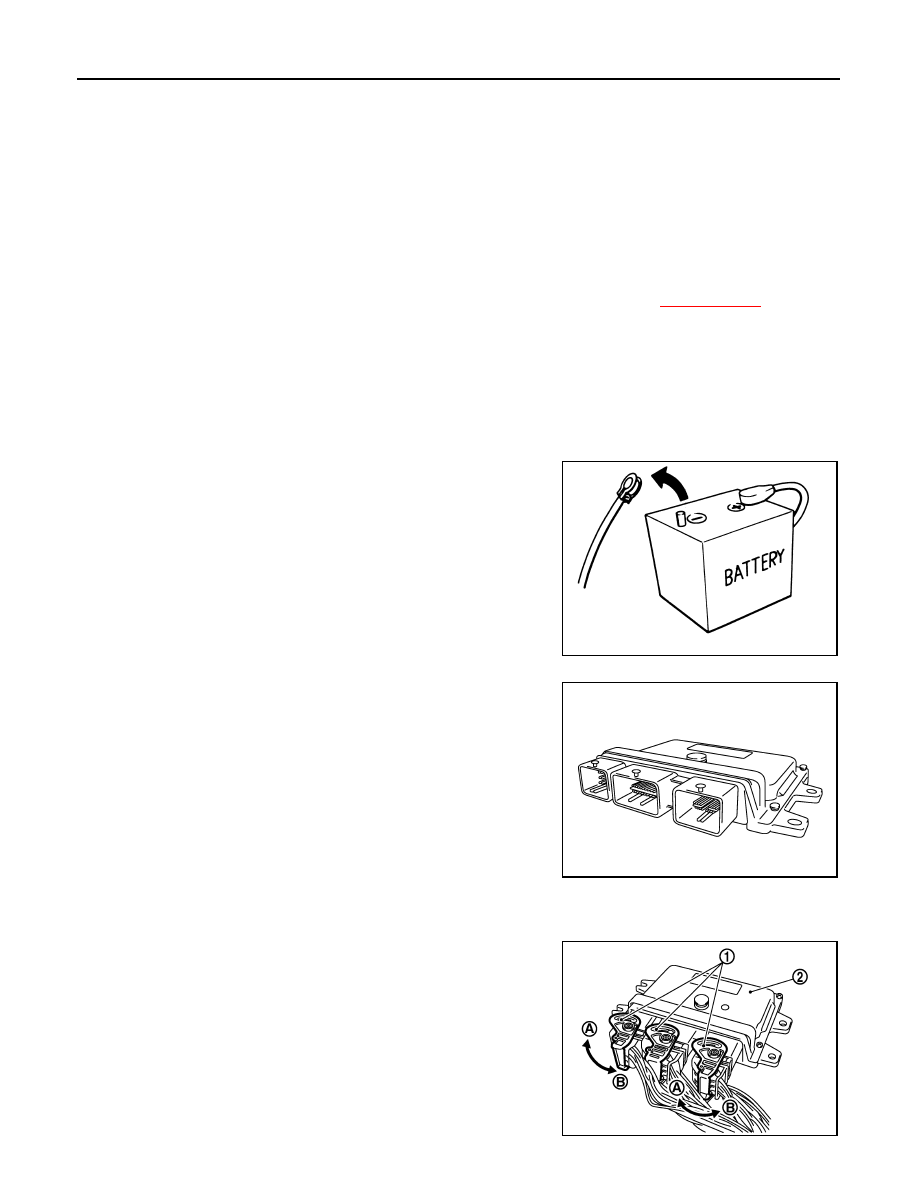

• Do not attempt to disconnect battery cables while engine is

running.

• Before connecting or disconnecting the ECM harness con-

nector, turn ignition switch OFF and disconnect negative bat-

tery cable. Failure to do so may damage the ECM because

battery voltage is applied to ECM even if ignition switch is

turned OFF.

• Before removing parts, turn ignition switch OFF and then dis-

connect battery ground cable.

• Do not disassemble ECM.

• If a battery cable is disconnected, the memory will return to

the ECM value.

The ECM will now start to self-control at its initial value.

Engine operation can vary slightly when the terminal is dis-

connected. However, this is not an indication of a malfunc-

tion. Do not replace parts because of a slight variation.

• If the battery is disconnected, the following emission-related

diagnostic information will be lost within 24 hours.

- Diagnostic trouble codes

- 1st trip diagnostic trouble codes

- Freeze frame data

- 1st trip freeze frame data

- System readiness test (SRT) codes

- Test values

• When connecting ECM harness connector (1), fasten (B) it

securely with a lever as far as it will go as shown in the figure.

SEF289H

2.

ECM

A.

Loosen

PBIA9222J

PBIB2947E