содержание .. 1308 1309 1310 1311 ..

Nissan Tiida C11. Manual - part 1310

REPAIR FOR COMPONENT PARTS

TM-291

< DISASSEMBLY AND ASSEMBLY >

[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

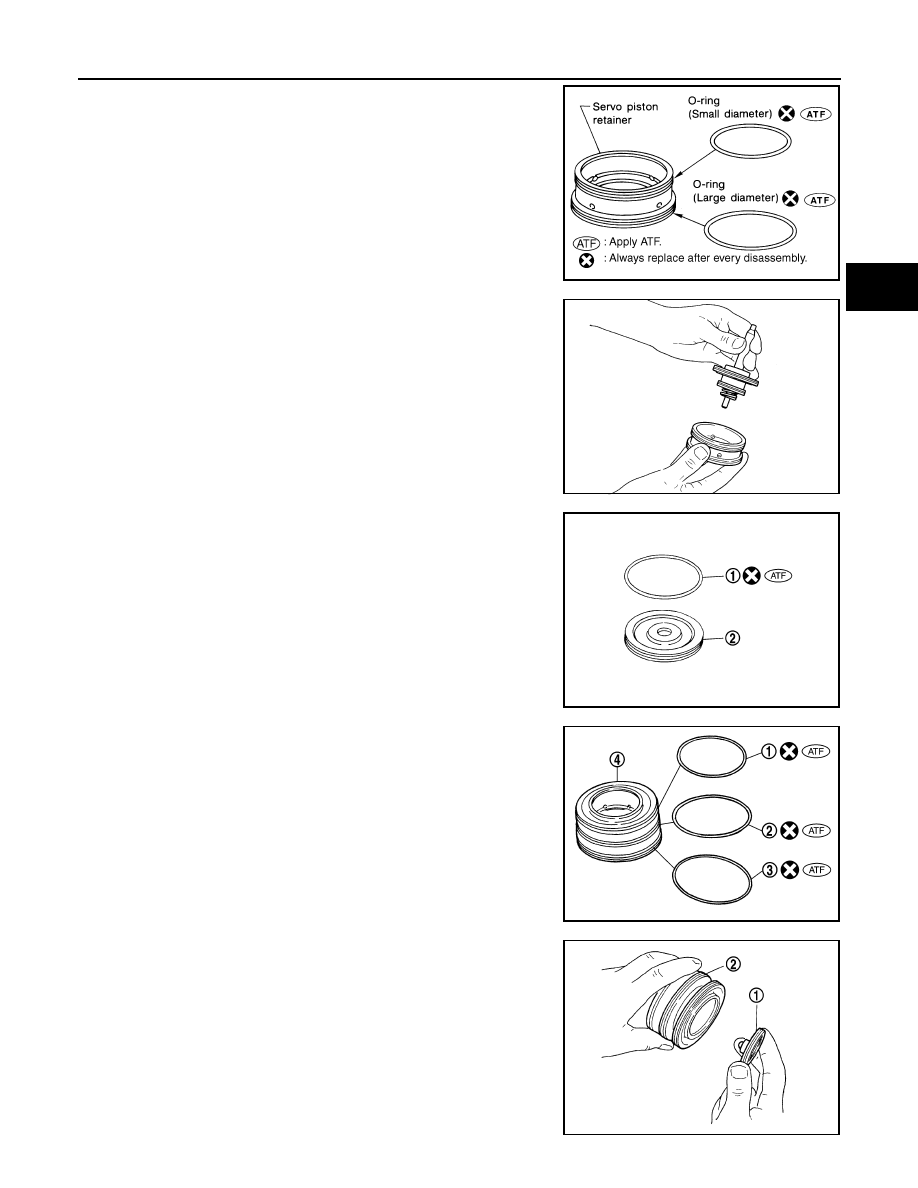

4.

Install O-rings to servo piston retainer

5.

Install band servo piston assembly to servo piston retainer by

pushing it inward.

6.

Install D-ring (1) to OD servo piston (2).

7.

Install O-rings (1), (2) and (3) to OD servo piston retainer (4).

(1): O-ring (small diameter)

(2): O-ring (medium diameter)

(3): O-ring (large diameter)

8.

Install OD servo piston (1) to OD servo piston retainer (2) as

shown.

SCIA3671E

SAT303D

SCIA7053E

SCIA6492J

SCIA7057E