содержание .. 1283 1284 1285 1286 ..

Nissan Tiida C11. Manual - part 1285

CONTROL SYSTEM

TM-191

< ON-VEHICLE REPAIR >

[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

CONTROL SYSTEM

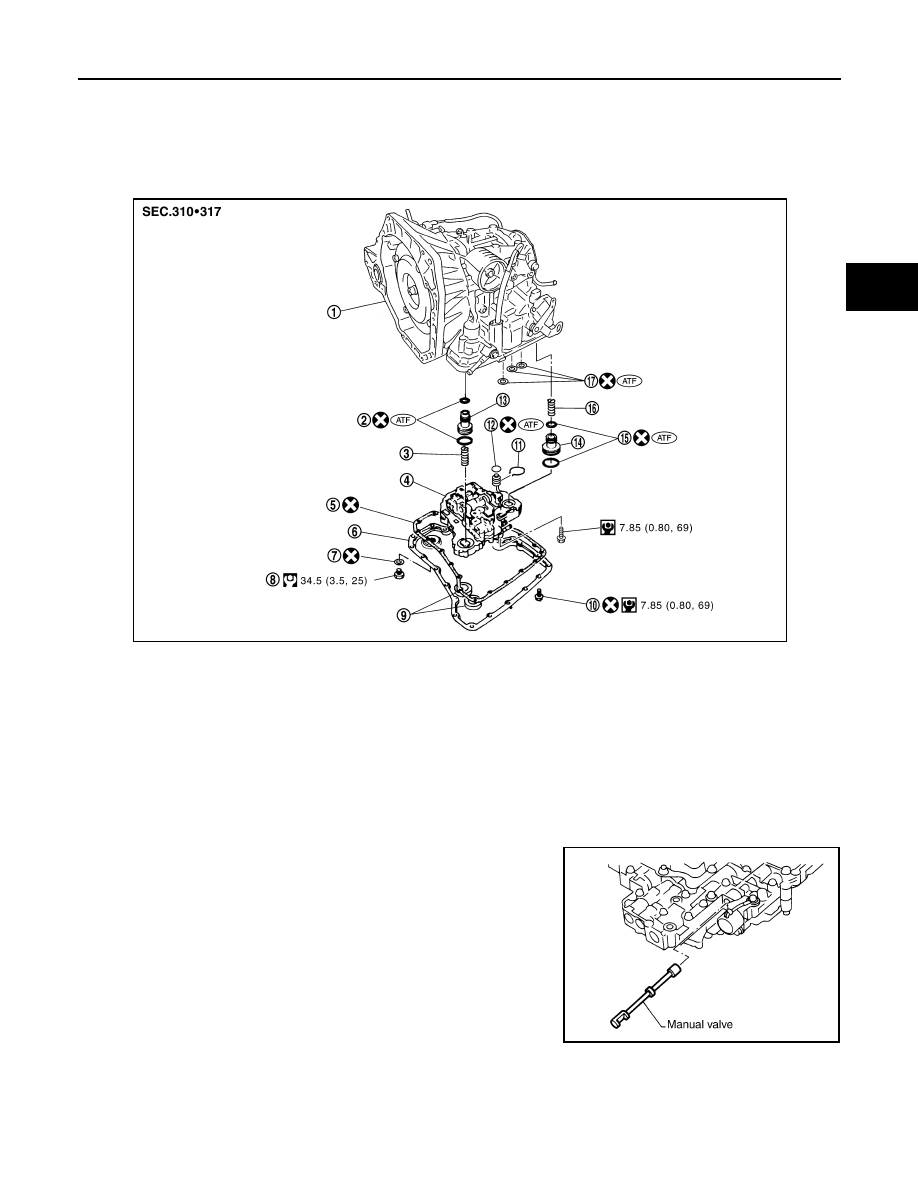

Control Valve Assembly and Accumulators

INFOID:0000000001733158

COMPONENTS

REMOVAL

Refer to the figure for control valve assembly and accumulators removal procedure.

CAUTION:

• Do not drop manual valve and servo release accumulator

return spring.

1.

A/T

2.

O-ring

3.

Return spring

4.

Control valve assembly

5.

Oil pan gasket

6.

Oil pan

7.

Drain plug gasket

8.

Drain plug

9.

Magnet

10. Oil pan fitting bolt

11.

Snap ring

12. O-ring

13. Servo release accumulator piston

14. N-D accumulator piston

15. O-ring

16. Return spring

17. Lip seal

SCIA6216J

SCIA3150E